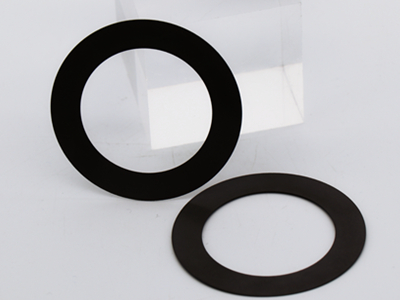

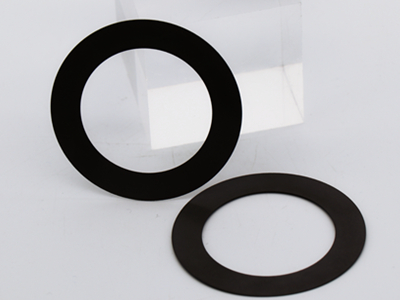

Resin diamond dicing blade for QFN package

Bond: resin bond

Model: 1A8

Used for processing: DFN, QFN, PCB, BGA, LGA, glass, and other materials.

Machine: ADT, DISCO, Infratec,etc…

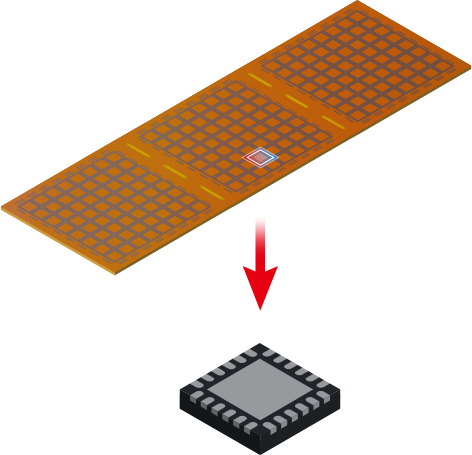

In order to meet the market demand, the manufacturing process of all kinds of electronic control components is also developing towards the direction of small volume, excellent performance and low energy consumption. Such as IC packaging DFN, QFN, BGA and other process types.

QFN packaging

QFN (Qual Flat No-lead Package) package is an extended package of QFN package. The pins of the DFN package are distributed on both sides of the package and the overall appearance is rectangular, while the pins of the QFN package are distributed on all four sides of the package and the overall appearance is square. The function of a QFN package is to connect the silicon die of the lC to the circuit board.

Characteristics of QFN package

Mainly reflected in three aspects: physical aspect, quality aspect and cost-effectiveness.

1. Physical aspects: small size and light weight

From the perspective of packaging efficiency (the ratio of chip area to packaging area tends to 1 for high efficiency), QFN packaging has the highest packaging efficiency among traditional packaging types. DIP packaging efficiency: 0.05~0.1, SOP: 0.1~0.2, QFN can achieve 0.3~0.4, QFN without heat dissipation pad can even achieve 0.5, description.

2. Quality: good heat dissipation, good electrical performance, and good reliability

There is usually a large-area exposed pad at the center of the bottom of the QFN package for heat conduction. This pad can be used as a direct heat dissipation channel to conduct the heat generated by the chip operation in the package; the pad is directly welded to the PCB after surface mounting. , PCB heat dissipation holes can diffuse excess power consumption into the copper ground plate to absorb excess heat, greatly improving the heat dissipation of the chip.

3. High cost performance

At present, IC packaging finished product cutting to the overall soft dicing blade, how to ensure the qualified rate of packaging finished product cutting? In addition to the product structure design, equipment precision, manufacturing process, and production environment, can not do without the precise selection of cutting blade and blade overall stability. The following is a brief introduction of our independent design, research and development, production of the overall soft blades, and actual processing cases.

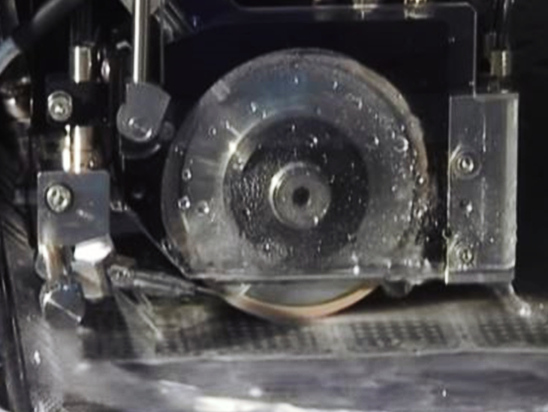

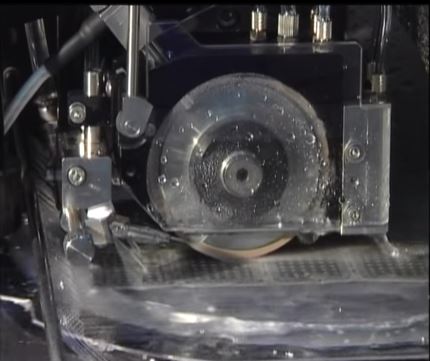

Principle of solid dicing blade machining QFN

The cutting blade is mounted on the soft blade flange of the cutting equipment’s spindle. Under high-speed rotation of the spindle at 20,000 to 30,000 RPM, diamond particles on the blade are impacted to break parts of the workpiece that need to be cut, and a Chip Pocket is used to timely remove cutting fragments to ensure product quality.

Introduction of solid dicing blade

Resin dicing blade is suited for cutting hard and brittle materials, such as QFN, sapphire, quartz glass, etc.

Application of resin diamond dicing blade

Main processing: DFN, QFN, PCB, BGA, LGA, glass, and other materials.

Through concentration, binder and diamond particle adjustment, it can effectively improve the processing quality, and blade utilization rate and solve common quality problems, such as metal burr, product layering, pin tin-melting, cutting process cutter, serpentine cutting, breakage, etc.

Case of resin diamond blade for QFN package

| Machine Type | DISCO 3350 |

| Product Type | DFN 2*2 |

| Product Size | 256*70mm |

| Coolant temperature | 12±2° |

| Product Material | Copper+Epoxy Resin |

| Cutting Mode | Single shaft cut through |

| Processing Method | UV film cut |

| Product Thickness | 0.75mm |

| Cutting slot width | 0.3mm |

| Dicing Blade | 1A8 SD240 58*0.3*40 |

| Speed of mainshaft | 25000rpm |

| Die size | 2.0mm*2.0mm |

| Flow rate | 1.5L/m |

| Feed Speed | 40mm/s |

| Machining Efficiency | 15 minutes |

| Cutting Depth | 0.1mm |

| Film Thickness | 0.15mm |

| Cutting Life | About 2000m |

Cutting Effect:

No burr, fracture and metal lamination were examined under 40 power microscope.

By selecting the suitable processing consumables, cooperating with scientific processing parameters, makes the cutting processing easier, we can offer high performance, high precision, difficult to market, good quality, long service life, reasonable price cutting blade, as well as the overall solution, to help customers enhance the level of technology and win more market.

| Grit Type | OD (mm) | ID(mm) | T(mm) | Grit Size |

| 1A8 SD / CBN | 50.8 | 25.4 | 0.07 – 0.3 | #200 – #3000 |

| 57.1 | 38.1 | |||

| 50.8-76.2 | 40 | |||

| 101.6 ,114.3 | 69.8 | |||

| 101.6, 114.3, 127 | 76.2 | |||

| 108.1, 127 | 88.82 | |||

| 108.1, 127 | 88.9 | |||

| Special size can be designed depending on customers’ requirement | ||||

Related Products

-

Metal bond Diamond Dicing Blades

Metal bond Diamond Dicing BladesMetal bond Diamond Dicing Blades

-

Electroformed Diamond Dicing Blade - Hub Type

Electroformed Diamond Dicing Blade - Hub TypeElectroformed Diamond Dicing Blade – Hub Type

-

Resin Diamond Dicing Blade for Silicon Wafer

Resin Diamond Dicing Blade for Silicon WaferResin Diamond Dicing Blade for Silicon Wafer

-

Diamond Dicing Blades For Wafer Scribing

Diamond Dicing Blades For Wafer ScribingDiamond Dicing Blades For Wafer Scribing

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.