Precision Pinch and Peel Grinding

What is pinch and peel grinding ?

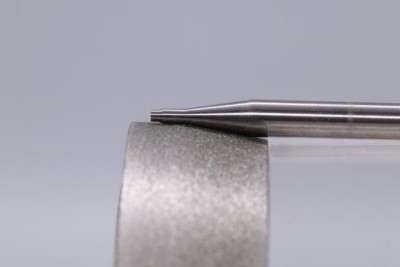

Precision Pinch and Peel Grinding belongs to cylindrical grinding, which refers to high-speed cylindrical grinding of various cylindrical and non-cylindrical shaft workpieces. During grinding, the grinding wheel rotates at high speed (usually 90-150 m/s), and moves axially with a certain grinding depth to achieve axial feed (>100 mm/min), and peel the material from the surface of the workpiece. Very thin, the rotational speed of the workpiece during grinding needs to be high enough to avoid the helical pattern.

Application field of peel step grinding (can replace traditional form plunge grinding and hard turning)

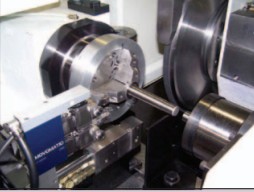

– Used for high-precision CNC cylindrical grinding machines. It is widely used in milling cutters, drills, taps, non-standard carbide rotary tools and other front-process forming step difference cylindrical grinding.

– The automotive industry is mainly used for the grinding of transmissions, drive shafts, gears, etc.

– The two main markets for peel (and extrusion) grinding are ground components and cutting tool blanks. Suitable for grinding precision punches, miniature pins, mold parts, etc.

– Not only for the preparation of cylindrical blanks, but also for non-circular applications. Especially suitable for applications requiring flat, threaded and non-circular punches

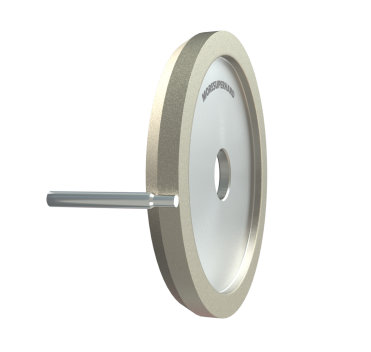

Specifications and parameters of peel grinding wheel

– When choosing a peel grinder, you need overall high stiffness and a good bearing system. Wheel speed should be in the range of 90-140 m/sec and rp in the range of 1000 to 10,000

– Grinding workpiece diameter range: 0.05 – 20.0mm

– Narrow wheels typically 0.25″ (6.4 mm) wide or less to grind parts

– Sintered electroplated bond wheels are recommended. Only about 25% of applications use vitrified superabrasives. Wheel speed is usually in the range of 80-110 m/sec

– Vitrified cbn wheel for peel grinding, which has also been shown to be more efficient on difficult-to-cut materials such as Inconel and soft stainless steel

Case- Aerospace manufacturer

Application: Tapered Bolt Grind

(Inconel 718)

Configuration: Straight wheel, CBN (vitrified)

Process: High-speed “peel” grind: multi-pass. Grinds head-end shoulder, fillet radius, tapered body diameter, transition angle, thread-roll diameter and nose-end angle

Attributes: Diameter tolerance +/- .0002”

Surface finish: 16 Ra

Dressing: rotary diamond dresser