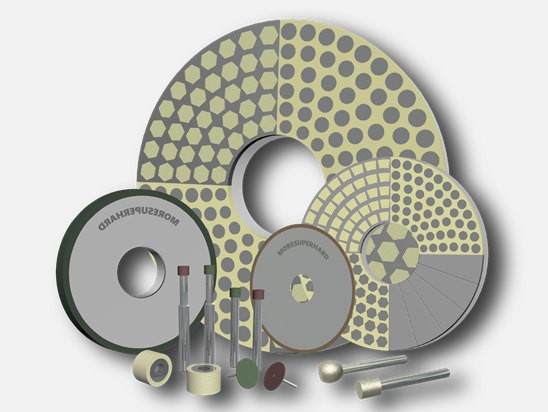

Grinding Wheels for Photovoltaic Industry

Soulution for Photovoltaic Industry:

Metal bond diamond grinidng wheel for cylinrical and flat grinding ingot rod

Electropalted band saw balde for cutting ingot

Diamond double disc grinding wheel for lapping silicon wafer

Polishing pad and diamond paste ,diamond compound foe polishing silicon wafer

Vitrified diamond back grinding wheel for back grinding silicon wafer

Diamond dicing blade(hubless/ hub-type) for dicing silicon wafer

Monocrystalline Silicon and Polycrystalline Silicon

Silicon is a hard and brittle material with a Mohs hardness of 6.5. It can be made into polycrystalline silicon and monocrystalline silicon according to the application.

Monocrystalline silicon is a relatively active non-metallic element. This crystal has a basically complete lattice structure and is a good semiconductor material with a purity of 99.9999%. It is mainly used in the manufacture of semiconductor devices and solar cells. The manufacturing method of monocrystalline silicon is usually to prepare polycrystalline silicon or amorphous silicon first, and then grow rod-shaped monocrystalline silicon from the melt by Czochralski method or suspension zone melting method.

Polycrystalline silicon is a form of elemental silicon. When molten elemental silicon is solidified under supercooled conditions, silicon atoms are arranged in the form of diamond lattices to form many crystal nuclei. If these nuclei grow into crystal grains with different crystal plane orientations, and these The grains combine to crystallize into polysilicon.

Polycrystalline silicon is the direct raw material for the production of monocrystalline silicon, and is the basic electronic information material for semiconductor devices such as contemporary artificial intelligence, automatic control, information processing, and photoelectric conversion. Known as “the cornerstone of the microelectronics building”.

Diamond grinding wheels are most widely used in the processing of hard and brittle materials such as crystalline silicon and sapphire. In the photovoltaic industry, it is mainly used in the cylindrical grinding of monocrystalline silicon, and the flat grinding, chamfering polycrystalline silicon rods.

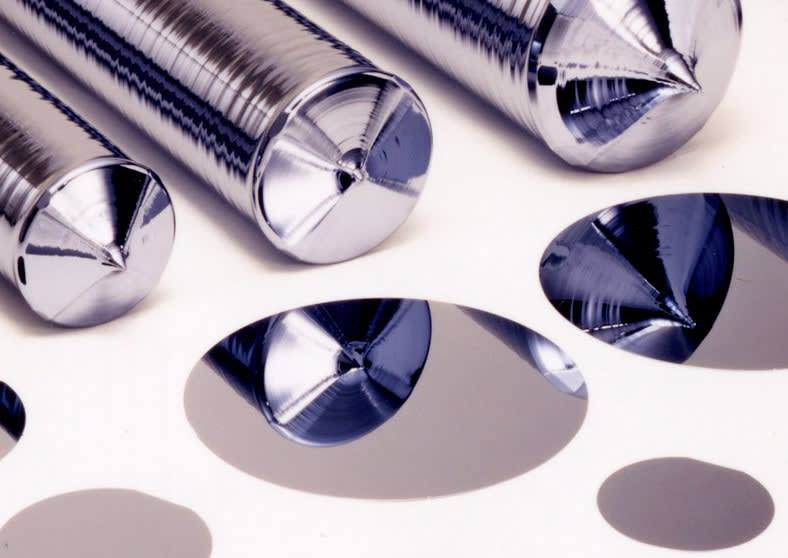

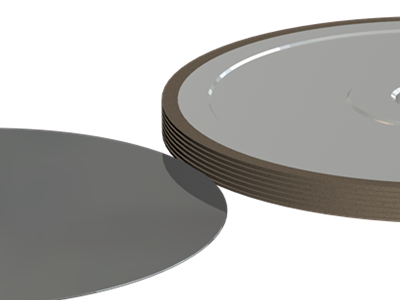

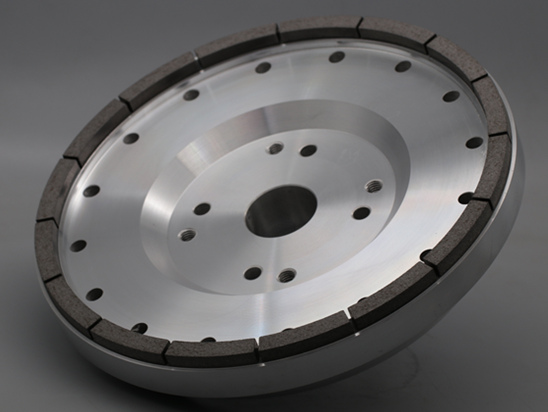

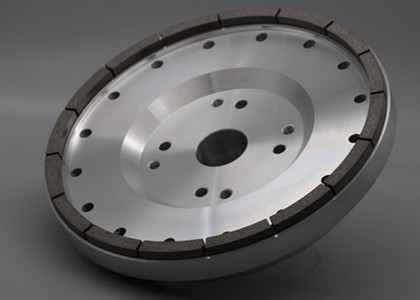

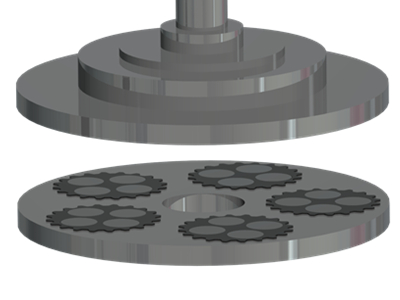

Cylindrical grinding wheel for monocrystal silicon rod

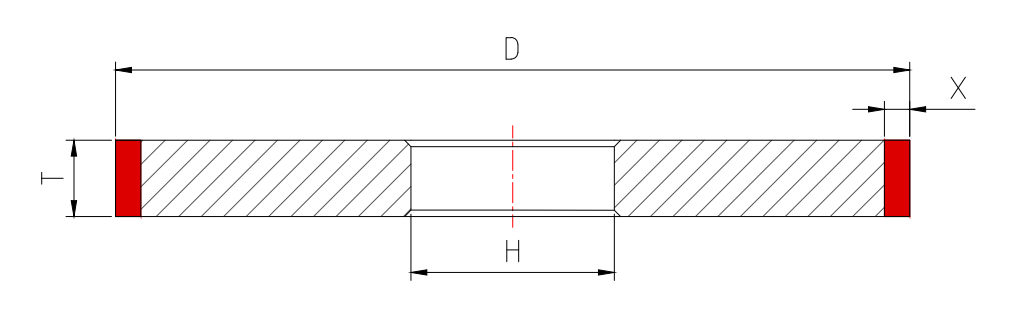

Moreduperhard metal diamond cylindrical grinding wheel for singlecrystal silicon, the general size specification is 1A1 300*25 (35, 40)*127*7, there are two types of single diamond layer and double diamond layer.

Combined spherical grinding wheel, multi-grain size (D 120/140, 200/230, W40) combination, can obtain high processing efficiency and surface quality at the same time.

Application of cylindrical diamond grinding wheel

Cylindrical diamond grinding wheel mainly used for flat grinding and chamfering of polycrystalline silicon, flat and cylindrical grinding monocrystalline silicon.

Characteristics of cylindrical diamond grinding wheel:

* High speed and high efficiency grinding

* Long life span

* High efficiency on stock removal

* Less damage and good finish of workpiece surface

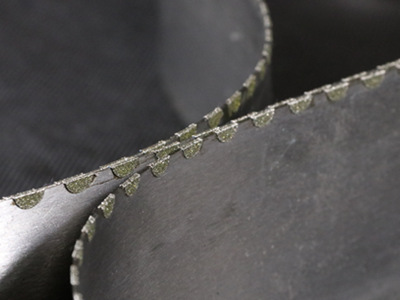

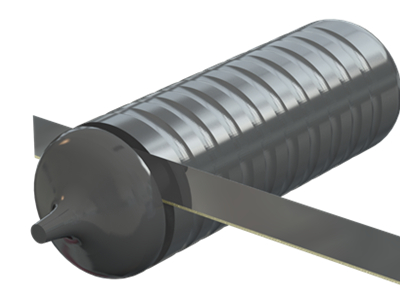

Cutting crystal silicon

Moresuperhard provide electropalted diamond band saw with excellent cutting surface, the highest level of precision at high cutting speeds and performance and high efficiency to cut the sapphire crystal rod into thin wafers. The electroplated diamond abnd saw has three tooth edge for selection: Continuous Shape, Segmented Shape(half-moon shape) and Serrated Shape.

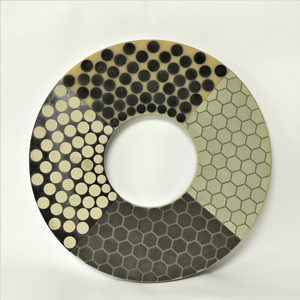

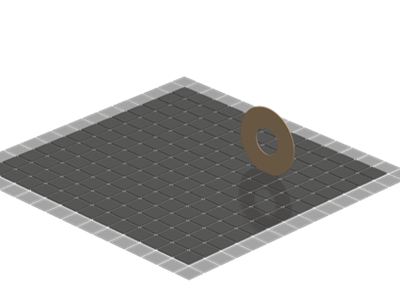

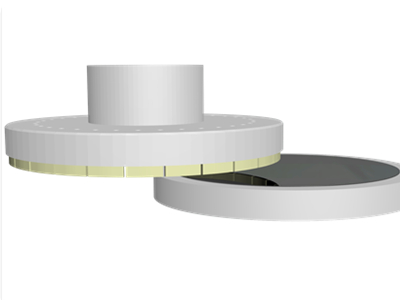

Grinding and lapping

Remove the chip cutting damage layer caused by slicing and improve the wafer flatness. It is divided into coarse grinding and fine grinding, and the abrasive products mainly include diamond double sided grinding disc, PU polishing pad, diamond paste and so on.

CMP polishing improves wafer roughness by CMP polishing, and makes its surface reach epitaxial wafer epitaxial precision. Polishing pad and polishing compound are often used, suitable for precision grinding and polishing of silicon carbide, silicon nitride, gallium arsenide and other semiconductor materials.

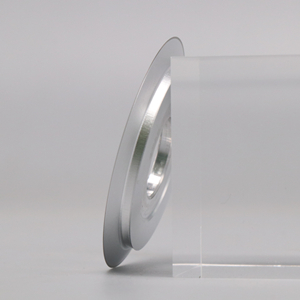

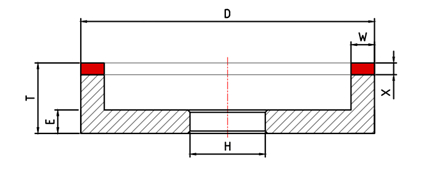

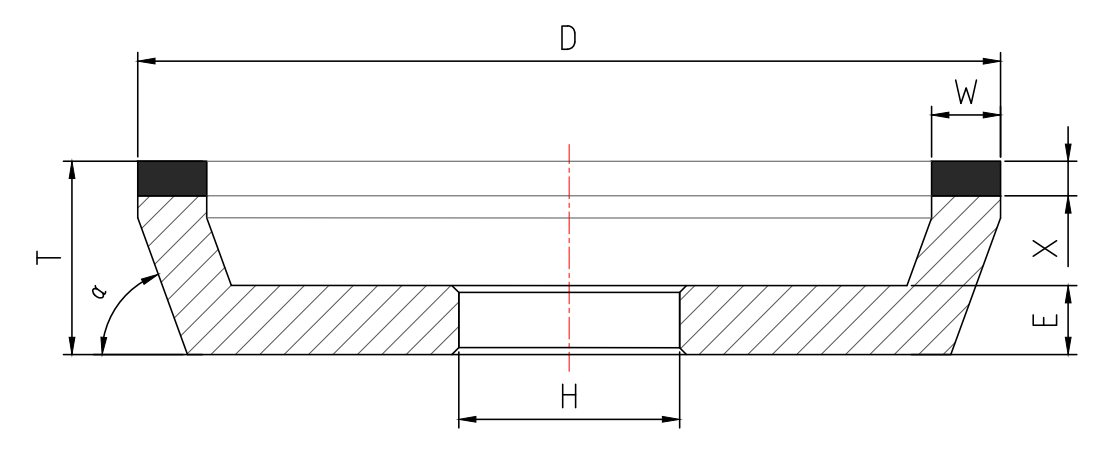

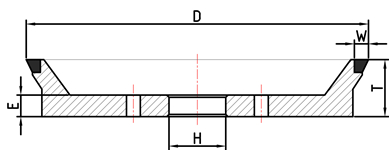

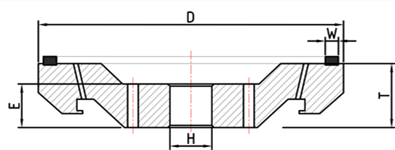

Chamfering grinding wheel

Metal bond diamond edge grinding wheel is used to trim the wafer edge into an arc shape to improve the mechanical strength of the wafer edge and avoid defects caused by stress concentration. The 45 degree chamfering Angle is 0 ~ 0.2mm. Common size: 1FF1V/9 202*20*30*2.5, Moresuperhard metal diamond edge grinding wheel has high toughness and strength, high groove precision, long service life.

Metal diamond grinding wheel widely used for chamfering monocrystalline silicon grinding surface and polycrystalline silicon surface. The processing process is divided into rough grinding and fine grinding. The grit usually used 120/140,W40,W28,W20,etc…Size of chamfering grinding wheel:6A2 220*65*130*5*5 /6A2 200*60*80*5*5/ 11A2 100*28(40)*31.75(20)*5*5, etc.

Polishing tools for wafer

Wafer has a certain strength, the thinning wheel is used to control the wafer thickness, the wafer roughness is improved by polishing, and the surface reaches epitaxial wafer epitaxial precision. CMP polishing fluid is often used.

–CMP polishing pad, dressing tool

-Diamond paste and diamond compound

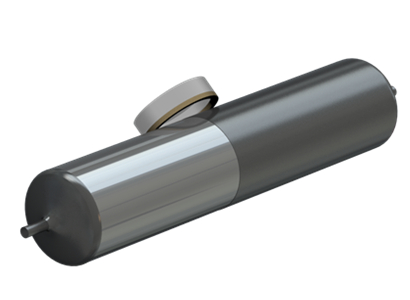

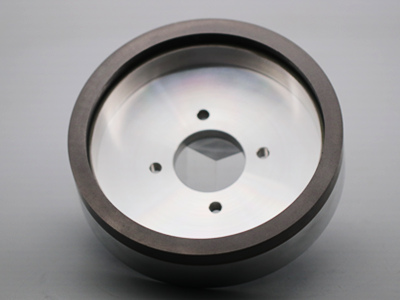

Back grinding wheel

Back grinding wheel for back thinning, front grinding and fine grinding of discrete devices, integrated circuit substrate silicon wafers, sapphire epitaxial wafers, silicon wafers, arsenide, GaN wafers, silicon-based chips, etc

Diamond dicing blade

The ultra-thin diamond dicing blade used in the sapphire industry is mainly divided into two types of bond: metal diamond dicing blade and resin diamond dicing blade.

Moresuperhard provide diamond dicing blade and diamond hubless dicing blade.

The diamond particle size is 270#-600#. Common specifications and models are 1A8, 58*0.2*40; 58 * 0.15 * 40; 56 * 0.1 * 40; 56 * 0.15 * 40, etc.

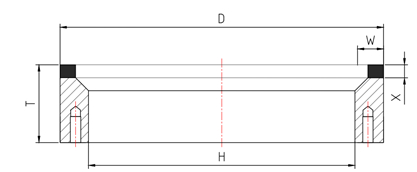

Specification of cylindrical diamond grinding wheel

| Type | Drawing | Dimension(D*T*H*X) |

| 6A2T |  |

220*65*130*5 |

| 6A2H |  |

200*35*76*5 |

| 200*60*80*5 | ||

| 11A2 |  |

100*28*34.75*5 |

| 100*40*20*5 | ||

| 1A1 |  |

300*35*127*5 |

| 300*35*127*7 | ||

| 300*35*127*10 | ||

| 6B9H/C |  |

300*50*48*10 |

| 300*50*48*20 | ||

| 6A2T/C |  |

250*60*38.1*10 |

| 250*60*38.1*15 |

Related Products

-

Back Grinding Wheel for LED Substrate

Back Grinding Wheel for LED Substrate

-

Diamond Wheels for Silicon Ingot, Cylindrical Grinding/ OD Grinding

Diamond Wheels for Silicon Ingot, Cylindrical Grinding/ OD Grinding

-

Polyurethane (PU) Polishing Pad for Wafer Surface

Polyurethane (PU) Polishing Pad for Wafer Surface

-

Electroplated Diamond Band Saw Blades

Electroplated Diamond Band Saw Blades

-

Back Grinding Wheel for Surface Grinding Various Silicon Wafer

Back Grinding Wheel for Surface Grinding Various Silicon Wafer

-

Electroformed Diamond Dicing Blade - Hub Type

Electroformed Diamond Dicing Blade – Hub Type

-

Diamond Dicing Blades For Wafer Scribing

Diamond Dicing Blades For Wafer Scribing

-

MoreSuperhard offers custom precision ceramic grinding, lapping and polishing service and solution.

High Precision Ceramic Grinding Lapping

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.