Vitrified CBN Grinding Wheel for Camshaft, Crankshaft, Bear Shaft

CBN Grinding wheel for grinding crankshaft , camshaft, cylinder head,, shaft, brake disc, etc

Model: 1A1 / 3A1 CBN wheel

Grinding Machine: Toyota (JKT), German Junker and Schaudt etc

High precision, good surface quality

High adhesion strength

Excellent performance

Reduced grinding forces

Easy dressing

Automotive Industry Grinding Solution

MORESUPERHARD provides a full grinding solution for engine machining,and transmission components grinding in automotive industry. We design and make special grinding wheels for cylinder block, cylinder head, crankshaft, camshaft, connecting rod, transmission case, gearbox shaft, clutch housing, and brake disc.

Vitrified bond CBN Grinding Wheel is suitable for precise and high-speed grinding the camshaft, crankshatf, gear shaft and crankpin, main journal, flange neck, thrust face and end face.

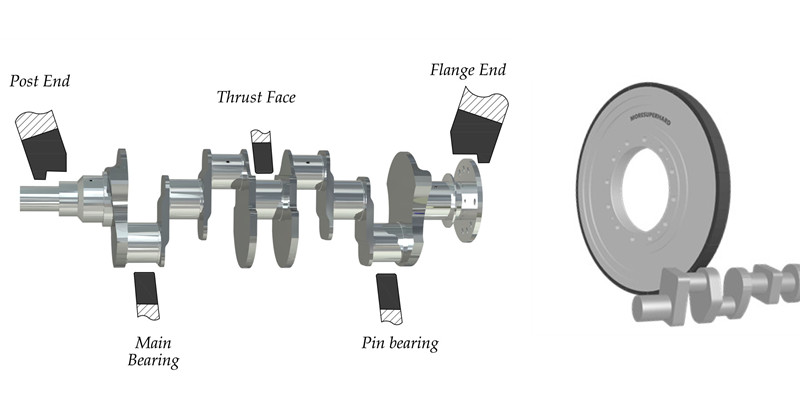

Crankshaft Grinding – Vitrified bonded CBN Wheel

Vitrified CBN grinding wheels are remarkable for preventing grinding burns to the shoulder of the Crankshaft. CBN grinding wheel for crankshaft can equip with various high precision CNC crankshaft grinding machines, Suitable for high efficient, heavy grinding of Crankshaft pin grinding, Journal grinding. The wheel speed is generally 80m/s-120m/s.

The main parts of the crankshaft to grind and regrind, include

► Main Bearing

► Rod Journals / Crankpin Journals

► Flywheel Flange End

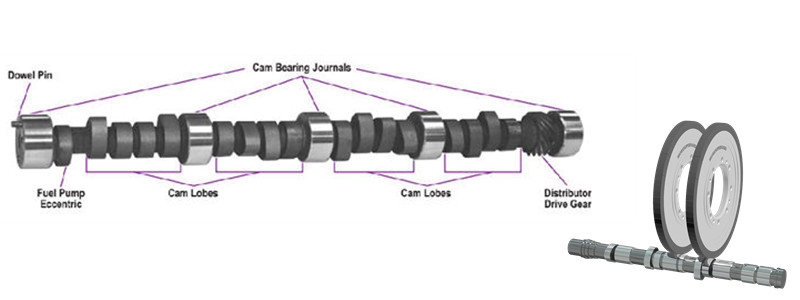

Camshaft Grinding – Vitrified bonded

The main parts of the camshaft to grind and regrind, include

► Camshaft main journals

► Cam (fixed on shaft)

► Cams (single)

► Camshaft tube

Materials to grind

Cast iron: Chilled cast iron, nodular cast iron, grey cast iron, alloy cast iron and etc

Steel: 20Cr, GCr15, CF53, 45# steel, 55# steel, 80B high carbon steel and etc

Suitable grinding machines

LANDIS: LT1, LT2

SCHAUDT: CF41, CF61, ZEUSMX, ZX

NAXOS: NAXOS-UNION, P310*1250, Gf70

JUNKER: JUCAM5002/10, JUCAM500, JUCRANK5000,6000

TOYODA: GCS63, GL5P-63, GL6P-100, GCH120B, GC32M-63, GCH63B, GL63M-T

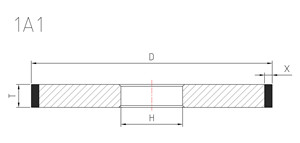

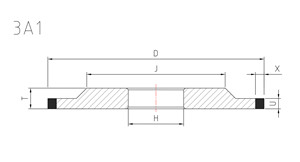

| Models | Profile Sketches | Spec. | |

| 1A1 |  |

1A1-D-T-H-X | |

| D | 200-750 | ||

| T | 15-70 | ||

| X | 3-10 | ||

| 3A1 |  |

3A1-D*T*H*X | |

| D | 300-950 | ||

| T | 5-10 | ||

| X | 10-500 | ||

The case of double ends vitrified cbn wheel for grinding cam lobes of camshaft

| Model/ Size | 120*15*66*(21+17) Double ends vitrified bond CBN grinding wheel | |

| Grinding Machine | Applicable Grinding Machine | Toyoda (JKT) |

| Workpiece | Workpiece | Cam lobes of camshaft |

| Workpiece Material | GCr15 | |

| Hardness of grinding layer | HRC58-62 | |

| Grinding allowance | Diameter: 1.2mm Rough grinding (Φ0.99mm, speed 0.08mm/r) Semi-finishing( Φ0.11mm, speed 0.03mm/ r) Fine grinding (Φ0.02mm, speed 0.01mm/r) |

|

| Grinding Parameter | Wheel speed (m/s) | 72m/s |

| Roughness after grinding | Ra≤0.64 | |

| Grinding time | 66″ | |

| Dressing Parameter | Dressing Tool | Sintering diamond roller |

| Cooling Liquid

|

oil cooling | |

| Grinding Wheel Life | grind about 8750 pieces | |

Related Products

-

Moresuperhard produce various type vitrified diamond and CBN grinding wheel for different industries parts grinding

Vitrified diamond and CBN grinding wheel

-

Diamond Pencil Edge Grinding Wheel for Auto Glass

Diamond Pencil Edge Grinding Wheel for Auto Glass

-

Vitrified CBN Wheel for finishing grinding cam lobes Camshaft

Vitrified CBN Wheel for finishing grinding cam lobes Camshaft

-

Vitrified bond CBN Groove Grinding wheels is suitable for rotary vane compressor, steering pump, vane pump rotor groove grinding, drive shaft grooving

Vitrified CBN Grinding Wheel for Rotor Slot

-

Vit CBN Grinding Wheel for steel part for automobile industry

CBN Grinding Wheel for steel part for automobile industry

-

CBN Grinding Wheel for Grinding camshaft

Vitrified CBN Grinding Wheel for Camshaft

-

CBN Grinding wheel for grinding crankshaft , camshaft, cylinder head,, shaft, brake disc, etc

Vitrified CBN Grinding Wheel for Camshaft, Crankshaft, Bear Shaft

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.