Engine Valve Grinding, CBN Grinding Wheel

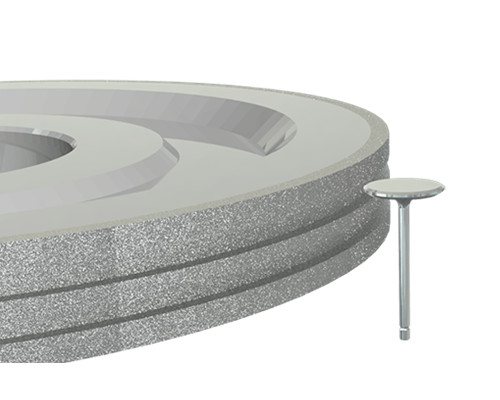

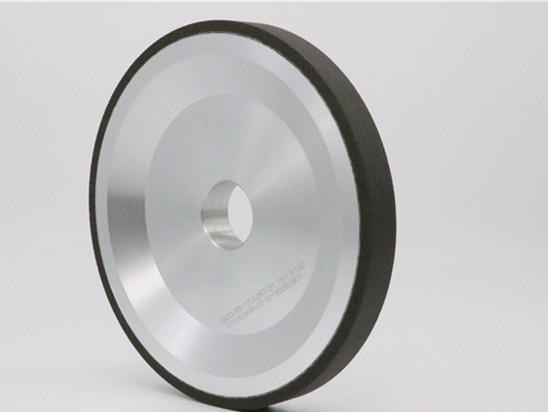

Elcetroplated /Vitrified / Metal CBN grinding wheel

Application: Grinding engine valves (inlet valves and exhasut valves) in cars, motorcycles, trucks, and other engine valves

Speed of CBN Wheel: 80-140 m/s

No need dressing

Engine Valve Grinding Wheel

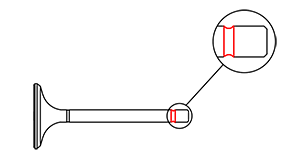

The Valve is responsible for the input of fuel into the engine and exhaust gas. The valve is an important part of the car. The grinding part is the clamping groove of the air lock and the lug line. The quality of the valve plays a vital role in ensuring the efficiency of the engine. In order to ensure the processing accuracy of the valve, the outer diameter of the valve, the cone surface, the umbrella, the large end face and other surfaces are to be completed by grinding.

Grinding is a major element in the engine valve machining chain, and is therefore largely responsible for component quality. The grinding wheels are used to process engine valves (inlet valves and exhasut valves) in cars, motorcycles, trucks, and other engine valves.

Valve is made of valve head, valve seat and valve stem three parts. The valve head is the entire lower area of the valve, with the valve face and inner rounded corners. The force produced by combustion pressure is applied here.

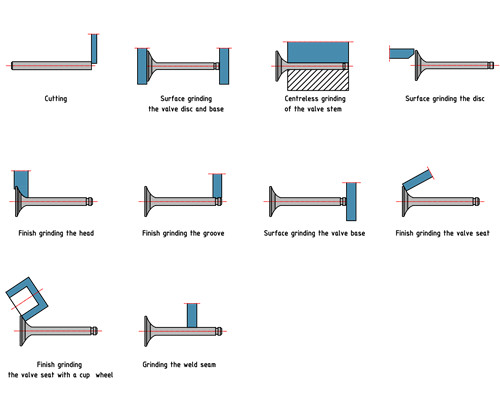

The main parts of valve grinding include

– Valve cut off grinding

– Valve shaft centerless grinding

– Valve head & seat grinding

– Valve groove & tip raduis grinding

– Valve stem end grinding

– Valve seat grinding

Valve base cutting

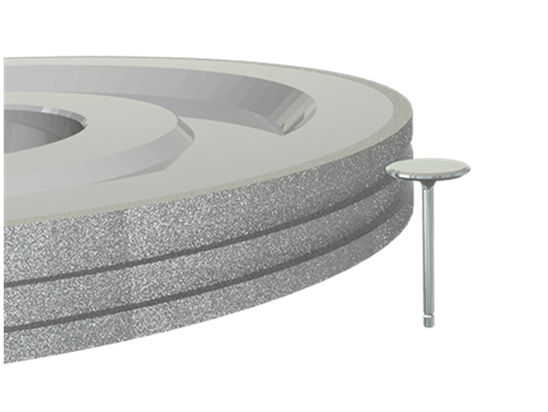

Using profile CBN high speed grinding wheel to cut the stem of engine valve in order to control the total length of engine valve. Metal CBN grinding wheel havev high material removal, good shape retention, is the ideal tool for cutting valve base. Using Moresuperhard metal CBN grinding wheel to achieve profile accuracy.

Valve Disc end face grinding

Metal CBN grinding wheel with fine grit is suitable for finish grinding the end face of vlave disc.

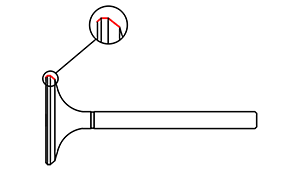

Valve keeper groove grinding

Many varieties of valves (including the valve with asymmetric groove shape of the keeper groove) contain the keeper groove in the quenching area of the rod end. Considering the stress effect of hot processing on the keeper groove, the keeper groove shape is often processed by forming the keeper groove grinding after quenching. Therefore, it is an effective way to ensure the machining accuracy of the air lock groove by using the forming grinding method of the valve keeper groove.

CBN grinding wheel has the characteristics of high sharpness and wear resistance, high hardness and large grinding ratio. Engine valve grinding processes include external grinding, valve disc seat grinding, chamfering grinding, arc grinding and other parts. Groove profiles using Moresuperhard Electroplated CBN grinding wheel, valve keeper groove profiles can be formed precisely with accuracy down to the micrometre.

Valve seat grinding

* For pre-grind valve seat:

Using Moresuperhard electroplated CBN grinding wheel .

* Fine grinding :

Vitrified CBN grinding wheel has good cutting performance, good thermal stability and chemical stability, good self-sharpeness, using Moresuperhard vitrified CBN diamond grinding wheel can achieve high precision valve seat. Regular dressing can guarantees constant component quality of valve seat.

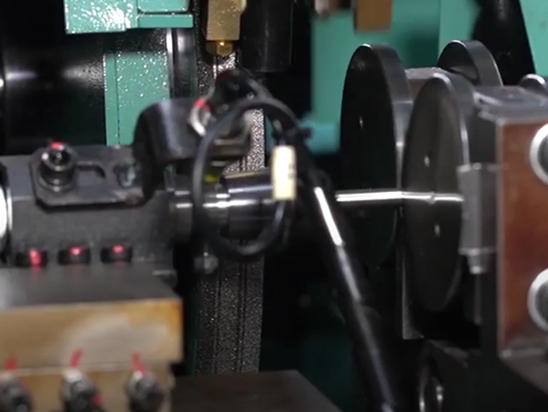

How to grind valve ?

| Parts | Grinding method |

| Valve stem | Centerless grinding |

| Valve head/seat/ keeper groove | External cylindrical grinding |

| Valve disc end face | Side grinding |

| Valve base | Cutting |

The Cases of Engine Valve Grinding

1. Grinding of valve head: (valve material: high nickel material)

| Product name | Rough grinding head (external circle + cone) 60° grinding wheel |

| Specifications | 510D-30T-203.2H-60° |

| Binding agent | Electroplated |

| Weight | 20-25Kg |

| Dynamic balance | ≤0.5g |

| Installation requirements | Radial runout&end runout ≤0.003mm |

| Workpiece | |

| Margin | φ0.5-1mm |

| Material | Nickel 30(High-nickel) |

| Working accuracy | Rz≤10μm |

| Other requirement | No scratches, burns, vibration marks and other defects on the surface |

| Machining effect | |

| Processing life | 100-120 thousand Pcs |

| Roughness | Rz≈5μm |

| Processing time | 10s |

| Stability | Batch processing size is stable, no need to debug |

2. Grinding of valve lock groove: (valve material: martensite/austenite)

| Products name | Locking groove grinding wheel |

| Specifications | 400D*24T*160H |

| Binding agent | Electroplated |

| Weight | 16-20kg |

| Dynamic balance | ≤0.5g |

| Installation requirements | Radial runout&end runout ≤0.003mm |

| Workpiece | |

| Margin | φ1.2mm |

| Material | Martensitic heat resistant steel |

| Working accuracy | Ra≤0.8μm |

| Other requirement | The grinding surface has the same texture, no chatter marks, burns, and no burrs. |

| Machining effect | |

| Processing life | 120-150 thousand Pcs |

| Roughness | Ra≤0.8μm |

| Processing time | 7~8s |

| Stability | Batch processing size is stable, no need to debug |

Related Products

-

Moresuperhard produce various type vitrified diamond and CBN grinding wheel for different industries parts grinding

Vitrified diamond and CBN grinding wheel

-

Diamond Pencil Edge Grinding Wheel for Auto Glass

Diamond Pencil Edge Grinding Wheel for Auto Glass

-

Vitrified CBN Wheel for finishing grinding cam lobes Camshaft

Vitrified CBN Wheel for finishing grinding cam lobes Camshaft

-

Vitrified bond CBN Groove Grinding wheels is suitable for rotary vane compressor, steering pump, vane pump rotor groove grinding, drive shaft grooving

Vitrified CBN Grinding Wheel for Rotor Slot

-

Vit CBN Grinding Wheel for steel part for automobile industry

CBN Grinding Wheel for steel part for automobile industry

-

Vitrified CBN grinding wheel are remarkable for preventing grinding burns to the shoulder of the Crankshaft. CBN Grinding Wheel For Crankshaft can equip with various high precision CNC Crankshaft Grinding Machines

Vitrified CBN Grinding Wheel for Crankshaft

-

CBN Grinding wheel for grinding crankshaft , camshaft, cylinder head,, shaft, brake disc, etc

Vitrified CBN Grinding Wheel for Camshaft, Crankshaft, Bear Shaft

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.