Cubic Boron Nitride (CBN) Grinding Wheel for Gear Hob Cutter

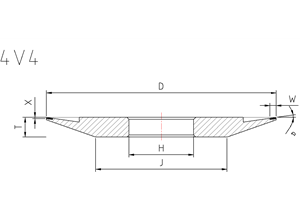

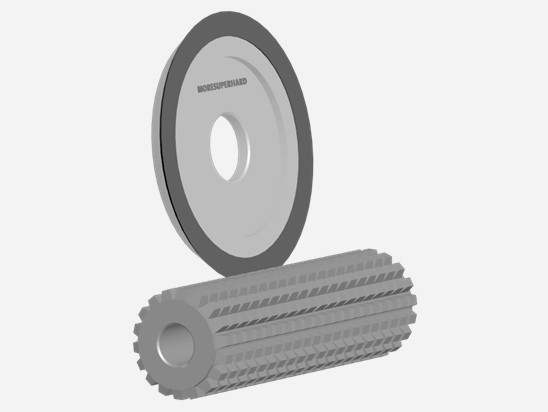

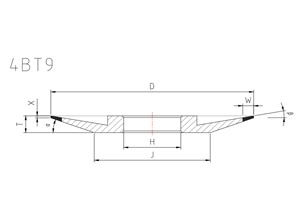

Model: 4BT9, 4M1, 4B1, 4B9, 12V2, 4V9, 4V4, 14EE1etc.

Bonded: resin bond, metal bond

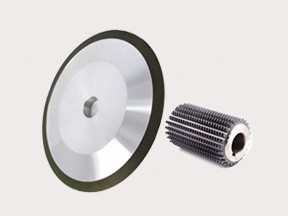

Application of cbn grinding wheels: forming and grinding of high speed steel (hss) gear hob and thread cutting tools

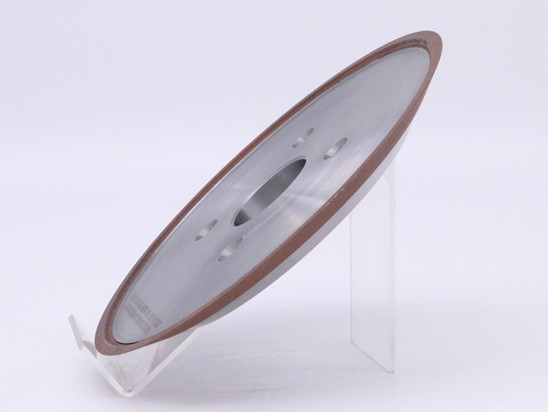

Width of CBN wheel abrasive layer is generally 3mm -5mm, and the thickness is between 2mm

Circular runout and axial runout value of the grinding wheel < 0.01 mm

Used Green silicon carbide grinding wheel dressing

Description of cbn wheel for gear hob grinding

Gear hob cutter is an important component in various mechanical rotation systems, so the surface finish and dimensional accuracy of gear hob cutter have high requirements. The choice of grinding wheel will also affect the service life of gear hob, and the hardness, wear resistance, high temperature stability, high temperature stability and thermal friction coefficient of grinding wheel directly affect the precision of hob grinding.

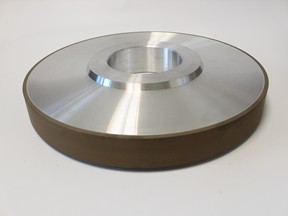

The CBN grinding wheel produced by MORESUPERHARD has the characteristics of high grinding efficiency, and effectively maintain the high precision and high life of the hob after grinding, greatly reducing the production cost, improving the processing efficiency and grinding accuracy, etc.

MORESUPERHARD ceramic CBN grinding wheel, resin CBN grinding wheel, metal CBN grinding wheel for gear hob rake surface grinding, forming grinding, and sharpening.

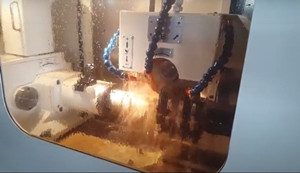

The single beveled CBN grinding wheel produced by MoreSuperhard can be used for hob grinding. Grinding wheel uses end grinding, the outer circle is very thin, can be ground to the bottom of the edge. CBN grinding wheels are used for forming and grinding of high-speed steel (hss) gear hob and thread cutting tools ( hardness above HRC60).

Advantages of cbn grinding wheel for gear hob cutter

– Grinding wheel uses end grinding, the outer circle is very thin, can be ground to the bottom of the edge.

– Good wear resistance and low loss

– Dry grinding and wet grinding

– High grinding precision, Reduced grinding forces

-Good surface finish

| Shape | D (mm) | W (mm) | H (mm) | X (mm) | T (mm) | V° |

| 4BT9 | 100 | 10 | 20 | 1 | 10 | 5 |

| 150 | 10 | 50.8 | 3 | 10 | 8 | |

| 4V4 | 100 | 6 | 20 | 1 | 10 | 10 |

| * other grinding wheels size can be customized | ||||||

The case of Metal bond CBN wheel for sharpening hob cutter

| Application | Hob Sharpening |

| Wheel sizes | 14EE1 – CBN grinding wheel-D150xT10 B30 C125 R0.09 |

| Machine | SEIWA |

| Coolant | Neat Oil |

| Wheel speed | 1000 1500rpm |

| Feed speed | 400mm/min |

| Work-piece | HSS HOB |

| Material | DM05 |

| Hardness | 68HRC |

| Depth of pass | 0,5mm |

| Roughness achieved | 0,1 µm Ra |

| Cycle time | 15 minutes |

Case of resin CBN grinding wheel for hob grinding

| Application | Hob Sharpening

|

| Wheel sizes | CBN grinding wheel-D200xT18.75xID76.2x4x3 |

| Machine | MITSUBISHI |

| Coolant | Neat Oil |

| Wheel speed | 1000- 1500rpm |

| Feed speed | 400mm/min |

| Work-piece | HSS HOB |

| Coating Material | S390 Powder Metallurgy |

| Hardness | 72HRC |

| Depth of pass | 0.1mm |

| Roughness achieved | 0.5 µm Ra |

| Cycle time | 20 minutes |

Related Products

-

External Grinding Carbide Roll, Resin diamond grinding wheel for HVOF carbide coating

External Grinding Carbide Roll, Resin diamond grinding wheel for HVOF carbide coating

-

Resin bond Diamond Wheel for Tungsten Carbide

Resin bond Diamond Wheel for Tungsten Carbide

-

Resin bond CBN grinding wheel for hardened steel

Resin bond CBN grinding wheel for hardened steel

-

cbn grinding wheels: forming and grinding of high speed steel (hss) gear hob and thread cutting tools

Cubic Boron Nitride (CBN) Grinding Wheel for Gear Hob Cutter

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.