Case of diamond core drill bit for processing glass

What is a diamond core drill bit?

Core drill bits are very convenient for drilling holes in hard surfaces such as ceramic, marble, granite and glass. Diamond drill bits get extra power from embedded diamonds.

The working process of a diamond drill bit is the process of continuously breaking rocks with diamonds. In the process of breaking rock, a certain pressure and rotation speed need to be applied to the drill bit so that the diamond can press into the rock and continue to break the rock. During this process, the drill bit and the rock rub against each other, which will continuously generate heat and a large amount of fine cuttings. Circulating fluid needs to be provided to cool the drill bit and take the cuttings away to improve the rock-breaking efficiency of the drill bit.

Diamond core drill bit is used for drilling and coring of glass, ceramics and other materials with high precision requirements:

* Glass rotary encoder processing

* Glass plate processing

* Hollow processing of various types of glass

* Hollow processing of ceramics, SiC, composite materials, crystal materials, etc.

* Manufacturing process: electroplating or sintering

* Commonly used base material: 45# steel

* Commonly used emery particle sizes: 120#, 240#

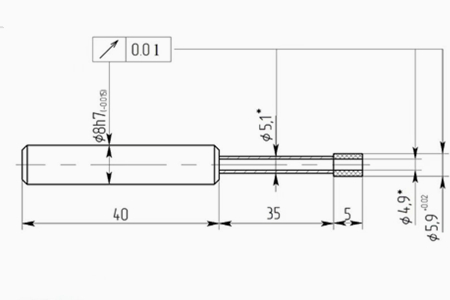

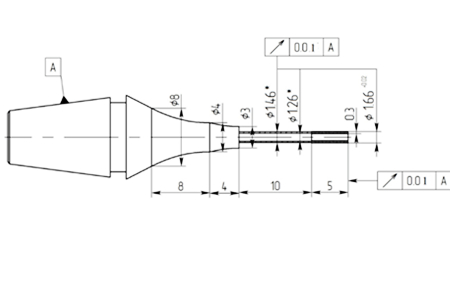

Recently one of our customer inquiry diamond core drill bit for drilling glass, lets see the drawing together:

Moresuperhard can provide cutting, grinding, drilling, and polishing services for the glass industry:

* Cutting solution: resin and metal diamond cut off wheel

* Grinding solution: metal dianond cup wheel, diamond profile wheel for glass edging/bevelling machine

* Polishing solution: X3000, X5000,10S Cerium Polishing Wheel, BK/BD polishing wheel

—EDITOR: Doris Hu, Eva Shang

—POST: Doris Hu