The difference between hubless dicing blade and hub type electrofromed dicing blade ?

What is dicing blade?

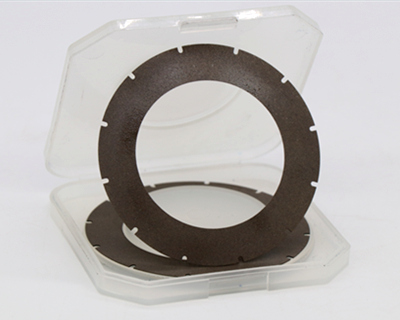

The diamond dicing blade is a kind of diamond cutting disc that needs different specifications for different models. Thin diamond cutting disc are usually used for slotting or cutting. In order to distinguish different cutting disc, thin diamond cutting disc are divided into ” hubless dicing blade and hub type electrofromed dicing blade”.

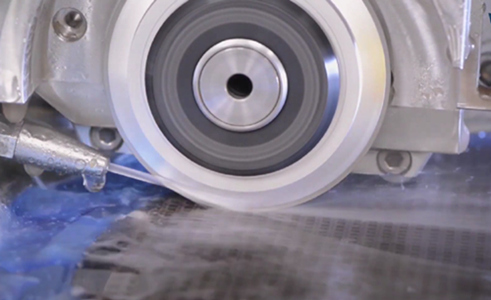

Dicing is used for cutting partially (scribing) or completely (singulation) a wide range of materials such as semiconductor compounds, ceramics, various glass types, composites…

Diamond dicing blades have diamond particles embedded in a bond matrix, hold together with a binder of either resin bond (soft strength), sintered metal bond (medium strength) or electroplated nickel bond (hard strength).

During dicing, each diamond particle embedded in the blade slowly breaks as it grinds away material from the substrate, and new particles captured in the matrix continuously offer new sharp point until the blade wears out. The concentration and the size of the diamond particles, together with the type and the thickness of the matrix, make the structure of the blades and have a direct impact on the finish quality of a cutting job.

The difference between hubless dicing blade and hub type electrofromed dicing blade?

1. Difference between shape

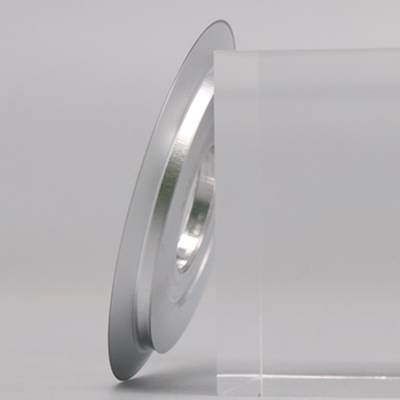

Generally, the dicing blade with thin circular ring is called “soft dicing blade”, and the grinding wheel with aluminum alloy tool rest is called “hard dicing blade”, and hard dicing blade is called hub type electroforming nickel bonded dicing blade.

2. Difference between forming process in manufacturing

In the manufacture of “soft dicing blade”, its forming method generally has electroforming, powder pressing sintering or powder pressing heating curing molding, and “hard dicing blade” generally adopts electroforming method.

And “hard dicing blade” can be directly installed and used without similar problems. However, if the installation of “soft dicing blade” meets the standard requirements, the two type dicing blade in use of precision and performance is the same.

3. Advantages of using dicing blade?

“Hard dicing blade” can be installed directly to the cutting equipment, as a result of the hard dicing blade blade has good grinding before they go out, so the new dicing blade with cutting can be normal use, very convenient: soft dicing blade “by dry to fixed on the cutter disc to install on the cutting equipment, and” soft dicing blade “in front of the factory can’t will edge grinding first, Therefore, the “soft dicing blade” should be polished before cutting, so that the sharpness of the edge can be used formally after meeting the cutting requirements. Therefore, “hubless diamond dicing blade” is not as convenient as “hub type electroformed diamond dicing blade” in use, and the operation skills of employees are relatively higher than “hub type electroformed dicing blade” requirements:

Hub type dicing blade used for cutting of silicon, compound semiconductor, glass wafers etc. Moresuperhard diamond dicing blade are suitable for use on all OEM manual and automatic wafer saws, including ADT, Disco, Accretech, Loadpoint etc.

4. Application range of the diamond dicing blade?

“Hub type electroformed diamond dicing blade” its abrasive adhesive only one kind, and “soft dicing blade” adhesive has a variety of, so “soft dicing blade” can be for different materials and choose different adhesive dicing blade for cutting, so “soft dicing blade” than “hard dicing blade” wider range of application.

Diamond dicing blade is used for grooving , cutting silicon wafer, compound semiconductors, glass and other materials in electronic information industry. Diamond dicing blade is one of new products developed . Moresuperhard dicing blades include diamond hub dicing blade and diamond hubless dicing blade. The binders include resin bond dicing blade, metal bond dicing blade and electroformed nickel dicing blade.

5. Cost of a dicing blade?

Because the sales price of “soft dicing blade” is cheaper than that of “hard dicing blade”, the dicing blade cost of “soft dicing blade” is lower. In addition, the “soft dicing blade” can be replaced after the outer circle is worn or the outer circle is knocked off. Generally, a blade can be used with three diameters (large, medium and small), which is very economic.

And “hard dicing blade” when the blade wear or knocked off, although you can also carry out blade regeneration, but regeneration must be carried out in the factory, they generally do not have this technology, and regeneration requires a certain cost, so the general use of units do not carry out blade regeneration, only for one-time use, waste is large. Therefore, the cost of dicing blade must be “soft dicing blade”

Precautions for using the diamond dicing blade:

1. Please check carefully before installing the cutting piece. If there is any gap or other damage, please stop using.

2. When the cutting piece is marked with rotation direction, it should be consistent with the rotation direction of the machine tool. On the contrary, the cutting is not sharp, it is difficult to play the performance of the cutting piece.

3. Do not use the cutting wheel that does not meet the requirements.

4. If any abnormality is found during cutting, stop the machine immediately and check the cause.

5. When the cutting is not sharp, the grinding wheel should be trimmed and edged. If continue to use, there will be overheating, overload and damage to the cutting piece.

6. When the cutting piece is rotating, it is strictly forbidden to cut by hand, not to touch the sand with hands and body

7. It is strictly forbidden to use the grinding wheel for other operations than grooving or cutting, so as to avoid abnormal occurrence due to uneven force.

—-EDITOR: Wooksong/ Doris Hu

—-POST: Doris Hu