Review of 2023 6th A&G EXPO

The 6th China International Abrasives and Grinding Exhibition has come to a successful conclusion. As a company focused on providing customers with cutting, grinding and polishing solutions, Moresuperhard also participated in this exhibition. Moresuperhard booth number is B33. We also live broadcast the booth and the grand event for everyone.

The 6th China International Abrasives and Grinding Exhibition has come to a successful conclusion. As a company focused on providing customers with cutting, grinding and polishing solutions, Moresuperhard also participated in this exhibition. Moresuperhard booth number is B33. We also live broadcast the booth and the grand event for everyone.

The exhibition lasts for three days, from September 20th to 22nd. During the exhibition, we will conduct multiple live broadcasts at home and abroad at different times, hoping to bring you a pleasant and meaningful live broadcast experience.

The 6th China (Zhengzhou) International Abrasives and Grinding Exhibition (referred to as “Zhengzhou Three Grinding Exhibition”), as an international professional exhibition for grinding solutions, started in 2011 and has gone through 12 spring and autumn years. It has a wide range of influence and popularity. The exhibition is based on the Central Plains urban agglomeration, taking root in the grinding capital gathering place, and continues to build an “efficient grinding, green manufacturing” industrial chain.

The exhibition will be divided into exhibition areas for abrasives, superhard materials, grinding equipment, machine tools and cutting tools.

Our friends have also made a lot of careful preparations for this exhibition, hoping to bring you a different experience. Friends on site are very welcome to visit our booth B33, have coffee, rest and negotiate.

It is said that this exhibition has prepared different surprises for everyone, but what exactly is the surprise?

There are not only exhibits on site, but also porcelain representing traditional Chinese culture.

Then you must be curious about what the relationship between porcelain and this exhibition is?

As one of the traditional Chinese handicrafts, ceramics inherits the history of Chinese culture and plays an important role in Chinese culture. Ceramics have high hardness, good heat resistance, good stability, sharpness, etc., and are widely used in daily life, such as containers, plates, knives, etc. It is precisely because of these factors that we produce ceramic diamond grinding wheels. These advantages are suitable for high temperature processing.

As a company that has successfully provided professional grinding solutions to nearly a thousand companies, “Moresuperhard” relies on its rich grinding experience and senior technical team to adhere to the concept of “using grinding to create more value than grinding” , aiming to provide higher-demand superhard tools for high-end manufacturing.

Moresuperhard has never stopped developing and improving products to provide customers with abrasive tools that are more in line with current market needs, have high grinding efficiency, economical production costs, and low environmental pollution. Our products cover aerospace, automobile, new energy, 3C, semiconductor, medical health, tools, petrochemical and other industries. We have built a variety of grinding systems to help customers solve processing problems with various grinding methods such as cylindrical grinding, end face grinding, surface grinding, step grinding, peripheral grinding, centerless grinding, optical curve grinding, etc.

We exhibited a series of ceramic diamond grinding wheels at this exhibition, as follows:

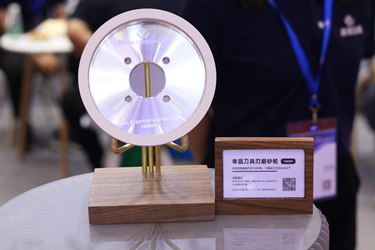

10000# Single crystal tool grinding ceramic diamond grinding wheel

10000# Single crystal tool grinding ceramic diamond grinding wheel

The finest particle size can be up to 10000#, and the tool chip can be below 2μm.

Compatible with grinding machines MYTECH MT-198NC, DMJR M50 CNC, EWAG rs15, COBORN rg9, etc…

At the same time, Moresupehard also agent Japanese OGURA ceramic diamond grinding wheels.

Vitrified diamond peripheral grinding wheel for indexable insert

Ceramic diamond peripheral grinding wheels are used for batch processing of PCD, PCBN, ceramic and carbide indexable inserts. They can be equipped with grinder models WAIDA, AGATHON350, AGATHON 400 PENTA, EWAG EWAMATIC, and other domestic and foreign high-precision grinders.

Vitrified diamond optical grinding wheel

The thickness of diamond can be as thin as 1mm, which meets the needs of high-precision processing and dressing. Compared with resin grinding wheels, the processing efficiency can be increased by 30%.

Vitrified diamond wafer back grinding wheel

Vitrified diamond wafer back grinding wheel

The grinding wheel particle size can be as fine as 15000#.

The vitrified diamond wafer back grinding wheel is suitable for thinning processing of discrete devices, integrated circuit substrate silicon wafers, sapphire substrates, LED substrate epitaxial wafers, chips, wafers, optical glass, electronic ceramic materials, etc.

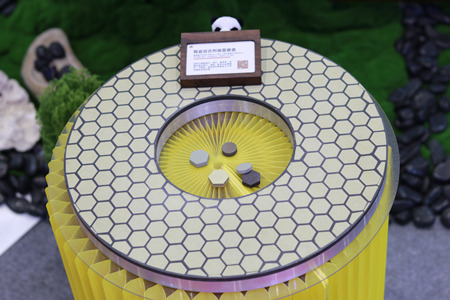

Vitrified diamond double disc grinding Wheel

Vitrified diamond double disc grinding Wheel

The maximum outer diameter of the grinding disc is 1500mm, the flatness of the processed workpiece is ≤0.002mm, the parallelism is 0.001 – 0.004mm, Ra=0.1-0.2μm.

Vitrified diamond double disc grinding Wheel is suitable for precision and efficient grinding of difficult-to-machine workpieces such as ceramic valve cores, valve discs, bearing rings, air conditioning compressor slides, valve plates, powder metallurgy parts, stainless steel, magnetic materials, etc.

Looking forward to meeting you at next A&G EXPO.

—EDITOR: Doris Hu

—POST: Doris Hu