Moresuperhard will participate 24th CIOE 2023

CIOE 2023 (The 24th China International Optoelectronic Exposition),is the largest and highest-level optoelectronic industry event in China,which will be held from September 6 to 8, 2023 at Shenzhen World Exhibition and Convention Center.

China International Optoelectronic Exposition (CIOE) is the world’s largest and most influential comprehensive exhibition of the optoelectronic industry, covering information communication, laser, infrared, ultraviolet, precision optics, chip materials, camera technology and application, intelligent sensing, new display, etc. The section displays cutting-edge optoelectronic innovation technologies and comprehensive solutions for optoelectronics and applications. In 2023, Moresuperhard Optoelectronics Group will go to Shenzhen again to participate in the exhibition, providing “cutting, grinding and polishing” for your processing of high-precision single crystal tools and photovoltaic semiconductor materials. solution. Welcome to our booth: 3E07 to have a visit, and we also prepare gifts for you.

At this exhibition, Moresuperhard will bring the following exhibits to meet you:

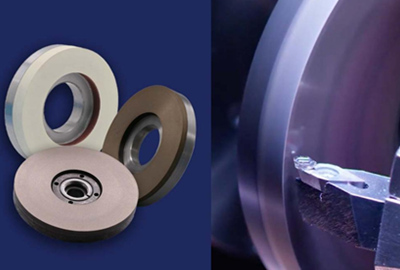

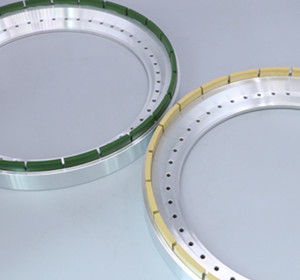

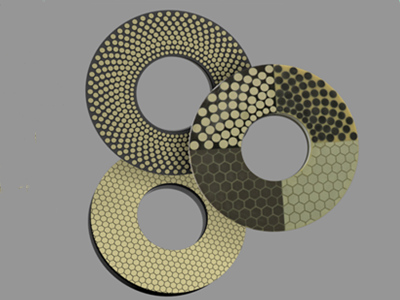

1. High precision diamond cutting disc

Precision diamond cutting discs are suitable for cutting wafers, PCB substrates, ceramics, optical fiber connectors, optical glass, electronic parts, semiconductor packaging, etc.

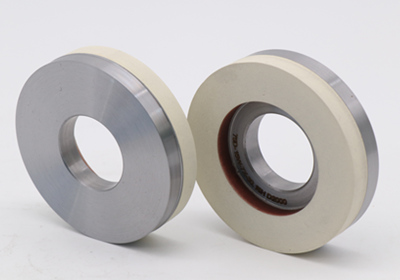

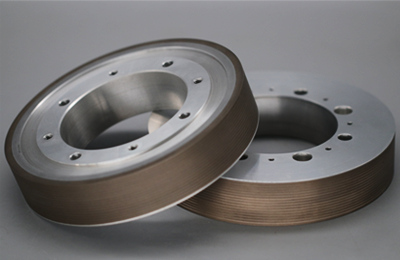

2. Vitrified diamond grinding wheel for single crystal diamond cutting tool

This series of rough/ fine grit ceramic diamond grinding wheel has been successfully matched with COBORN RG5 and RG9A, EWAG-RS15, FC-200D, MT-188, MT198NC and domestic and other well-known diamond tool grinders, with particle sizes ranging from rough grinding W40 to super fine grinding 10000#. This series of ceramic diamond grinding wheels can be used to grind the cutting edge on British PG3 or PG3B single crystal grinding machines.

| Surface roughness | Grit |

| Rough grinding | W40, W20 |

| Semi-fine grinding | W10,W7,W5 |

| Fine grinding | W3.5, W2.5,W1.5 |

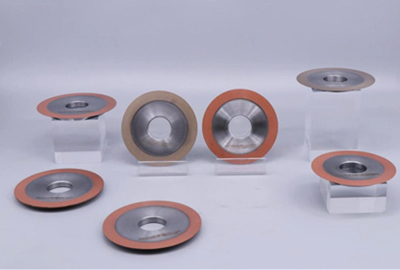

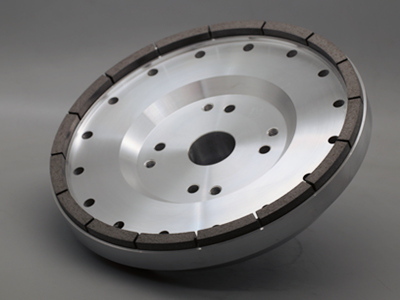

3. Optical profile grinding wheel

Optical profile grinding wheel grinding wheel is suitable for grinding precision grinding molds, punches, optical grinding and forming grinding cutting tools and precision instrument workpiece materials. In addition, optical prism processing grinding wheels will also be exhibited together.

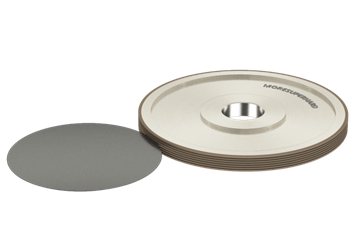

Back grinding wheels can be used for thinning chips, sapphire substrates, substrate epitaxial wafers, wafers, optical glass, etc.

5. Edge grinding wheel for wafer chamfering

The edge grinding wheel is used for chamfering and bevel grinding of semiconductor wafers such as silicon, silicon carbide, potassium arsenide, and sapphire, and semiconductor material substrates such as LCD&OLED&MLED, and glass.

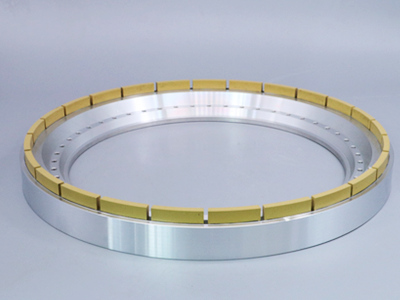

6. Diamond grinding wheels for photovoltaic industry

It is suitable for cylindrical grinding and roller grinding of single crystal silicon rods and polycrystalline silicon rods in the photovoltaic industry.

Realize double-sided simultaneous grinding of multiple semiconductor wafers and other semiconductor materials, greatly improving grinding efficiency. Double-sided grinding can effectively remove the wafer-cutting damage layer caused by slicing and improve the flatness of the wafer.

8. Polishing pad, polishing paste and compound

Improve the wafer roughness by CMP polishing, so that the surface can reach the precision of epitaxial wafer epitaxy, and use more polishing pads. The polishing liquid is suitable for silicon carbide, aluminum nitride, silicon nitride, phosphide steel, arsenide, nitride, etc. Precision grinding and polishing of semiconductor materials.

Moresuperhard is committed to process research and development and reform and innovation. Adhering to the concept of “creating more value with grinding than grinding”, it continues to provide customers and the market with high-quality “cutting, grinding and polishing” products for your high-precision Single crystal cutting tools, semiconductors, and precision optics industries provide a full range of customized high-efficiency “cutting, grinding and polishing” solutions to help customers truly achieve cost reduction and efficiency increase.

—EDITOR: Doris Hu, Julia Zhang

—POST: Doris Hu