RELATED BLOG

-

Why CBN grinding wheel superior to Diamond wheel in Grinding Nitinol (NiTi)

2026-02-11 -

How to Choose the Right Grinding Wheel for Rubber Grinding

2026-01-29 -

How to Choose the Right Vacuum Brazed Diamond Tool

2025-12-17 -

How to Select the Right Polishing Pad Material for Different Sapphire CMP Stages

2025-12-07 -

Which Grit Wheel Should You Choose for Wood Turning Tools?

2025-12-04 -

Difference Between CVD Diamond Roller Dresser and Electroplated Diamond Roller Dresser

2025-11-18

-

The difference between diamond sanding belt and diamond grinding belt

2022-08-04Both diamond abrasive belts and diamond grinding wheel are the cumulative effect of micro-cutting of the “micro-edge cutting tool” with high speed — abrasive particles, so their grinding mechanism is roughly the same. However, due to the different characteristics of sand belt composition and use mode, the grinding of diamond polishing belts is different from diamond wheel grinding in terms of both grinding mechanism and comprehensive grinding performance. The main performance is as follows

Learn More

-

How to select grinding fluid in different grinding methods?

2022-08-01During metal grinding process, it is very important to choose the right grinding fluid in order to obtain the ideal machining accuracy and surface quality. Different metal grinding processes have different processing phenomena and different requirements on grinding fluid, so the grinding fluid used is more different.

Learn More

-

The difference between hubless dicing blade and hub type electrofromed dicing blade ?

2022-07-18The diamond dicing blade is a kind of diamond cutting disc that needs different specifications for different models. Thin diamond cutting disc are usually used for slotting or cutting. In order to distinguish different cutting disc, thin diamond cutting disc are divided into ” hubless dicing blade and hub type electrofromed dicing blade”.

Learn More

-

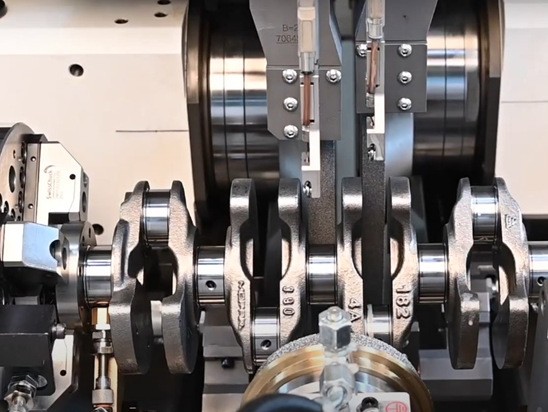

How to achieve high precision grinding crankshaft

2022-07-13Crankshaft is also a very unique part, no other part processing requires so many different processes, it is thin and long, the materials used in poor machining performance. Among them, the accuracy of thrust surface (including thrust journal and width) is more and more high, and R. A significant characteristic of thrust surface is that its contact area is much larger than that of other shaft collar sides, and the accuracy requirements are also much higher. Vitrified CBN grinding wheel is the ideal tool for crankshaft grinding, control is very sensitive, preventing burns during grinding.

Learn More

-

How to achieve high precision pinch and peel grinding?

2022-07-06For high precision CNC cylindrical peel grinding machine, widely used for profile cylindrical peel grionding former working procedure of milling cutter, drill bit, tapping, non – standard carbide rotary tools .

Learn More

-

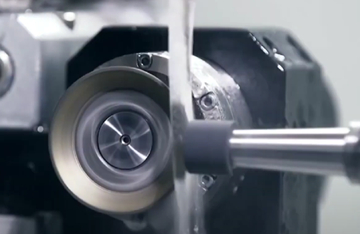

How to high precision rotor grooving?

2022-06-30The rotor is a key part of the vane pump/motor. The material is 38CrMoAlA and the surface of the rotor groove is nitrified. Because the size accuracy, shape and position tolerance and surface roughness of this part are high requirements, the groove is narrow and deep, so the grinding wheel should be considered to have chemical inertia and high hardness, not need dressing in the process of use, so the selection of vitrified or electroplated CBN grinding wheel is more suitable.

Learn More

-

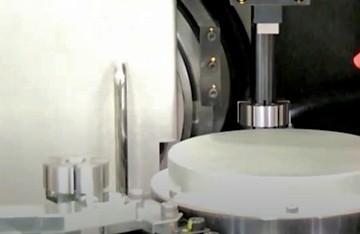

Do you know how centerelss grinding work?

2022-06-22Centerless grinding is on centerless grinding machine, which interacts with regulating wheel and supporting plate to grind workpiece cylinder. During grinding process, no spindle or fixture is used to locate and secure the workpiece, workpiece is between the grinding wheel and the regulating wheel, supported by the support plate below, and the regulating wheel drives the cylindrical workpiece to rotate on the pad iron. Centerless grinding can also be used for inner circle grinding. During machining, the outer circle of the workpiece is supported on the roller or the supporting block, and the workpiece is driven to rotate by the eccentric electromagnetic suction ring. The grinding wheel extends into the hole for grinding. Centerless inner circular grinding is usually used to grind inner groove of bearing ring on special grinding machine for bearing ring.

Learn More

-

Influence of dressing interval of CBN internal grinding wheel on grinding effect

2022-06-13CBN grinding wheel has high hardness and wear resistance, and the material removal rate of CBN grinding wheel is higher than that of ordinary grinding wheel.

Learn More

-

Learn about dressing of grinding wheel

2022-06-02In the grinding process, under the action of friction and extrusion, the edges and corners of the grinding wheel gradually become round and blunt, or in the grinding of tough materials, the grinding debris is often embedded in the pore of the grinding wheel surface, so that the surface of the grinding wheel is blocked, and finally the grinding wheel loses its cutting ability.

Learn More

-

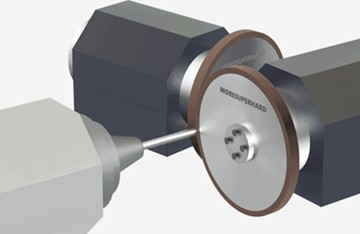

What problems should be paid attention to in the process of roller grinding machine?

2022-06-01The grinding efficiency of super hard abrasive is higher than conventional abrasive,Moresuperhard diamond grinding wheel used for WC hard alloy roll ring process, CBN grinding wheel used for HSS Roller process. Moresuperhard have resin/metal/ electroplated diamond grindng wheel for roll ring grinding and roll cylindrical grinding.

Learn More