High performance of diamond abrasive belt

What is diamond abrasive belt?

Diamond sanding abrasive belt is a kind of coated abrasive tool that synthetic diamond abrasive particles adhesive to a flexible and bendable substrate, that is, “abrasive cloth or sandpaper”.

Which industries can diamond abrasive belts be applied to?

Diamond sanding belt is especially suitable for the processing of hard and brittle non-metallic materials and non-ferrous metals, so it is widely used in hard and brittle materials such as stone, building materials, glass, special ceramics, monocrystalline silicon, polycrystalline silicon, precious jade, silicon aluminum alloy, hard alloy, etc. Grinding and polishing of complex shaped surfaces of products.

How many types of diamond abrasive belts?

Diamond abrasive belts are divided into three categories according to use, tool performance, and manufacturing difficulty: resin dispensing abrasive belts, resin fully coated abrasive belts, and electroplated dispensing abrasive belts.

What are the characteristics of diamond abrasive belt?

The biggest feature of diamond sanding belt is high grinding efficiency, high durability, smoothness, high gloss, and high-cost performance.

What is an electroplated diamond abrasive belt?

Electroplated diamond abrasive belt is a new type of superhard abrasive belt that distributes diamond on the substrate by electroplating, usually using nickel as the medium, depositing it on the wire mesh in two stages, and bonding it with a soft cloth base to form a ring. Coated abrasive products. Compared with ordinary abrasive belts, diamond electroplated abrasive belts have the dual characteristics of “hard” superhard materials and “soft” coated abrasives. The large chip space is conducive to heat dissipation, which improves the processing quality, the flexibility of the abrasive belt, and the chip removal capacity. It also has the environmental protection advantages of less dust and low noise during use.

Electroplated diamond abrasive belts have been widely used in grinding and polishing of hard and brittle materials such as glass, stone, ceramics, composite materials, crystal, aerospace, and silicon materials.

Grinding characteristics of electroplated diamond abrasive belt

Compared with diamond grinding wheel

The diamond grinding wheel is a rigid abrasive tool. During the grinding process, there are problems such as poor self-sharpening, easy edge chipping, and high product rejection rate. Especially for hard and brittle material workpieces that need to be processed into curved surfaces such as automobile windshields, using Rigid grinding wheel grinding, it is difficult to keep the original shape of the machined surface.

For example, when using a grinding wheel edging machine to grind the straight bottom edge of glass, it needs 6 diamond grinding wheels to complete, and the grinding feed speed is slow and the efficiency is low, which will easily cause cracking of glass thinner than 3mm. For shape grinding, a chamfering machine or a rounding machine is also required; while using a cross belt grinding machine, only two diamond electroplated abrasive belts can be used to complete the grinding of straight and curved edges. The entire operation is installed on a universal The working surface of the wheel is completed, and the grinding speed is fast, which is more suitable for the industrial production of the assembly line.

Compared with resin diamond abrasive belt

Resin diamond sanding belts use resin as a binder, but during the grinding process, heat accumulates next to the diamond, if it cannot be exported or discharged immediately, the temperature will rise immediately, causing the binder to melt, and the diamond has not yet fully functioned It will fall off and the service life will be short. Therefore, the diamond resin abrasive belt must be cooled with water for grinding, and the cost performance is far inferior to that of the diamond electroplated abrasive belt.

Application of electroplated diamond abrasive belt

Electroplated diamond abrasive belt grinding is a compound processing technology that uses flexible grinding tools to perform multiple functions of grinding, grinding and polishing. It has a “cold” effect and is especially suitable for hard and brittle non-metallic materials and non-ferrous metals. processing.

Glass processing

Electroplated diamond abrasive belts can be used for edging of automobile windshields, architectural glass and crystal glass, among which automobile windshield manufacturers are the main customers of large diamond abrasive belts. And with the development of the automobile industry, the demand for diamond electroplated abrasive belts will continue to increase.

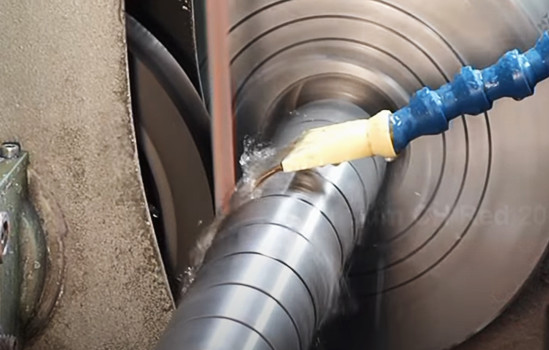

Super Hard Metal Alloy Coating

The superabrasive belt can replace the diamond grinding wheel to complete the complete grinding and polishing process, and is widely used in the thermal spraying industry, the production and repair of hydraulic cylinders and turbine blades, etc. For example, when grinding large tungsten carbide rollers in iron and steel plants, the roughness of 3.0 μm to 4.2 μm is usually required. This type of roller is slightly tapered. Usually, it takes 8 hours to complete the grinding and polishing if a diamond grinding wheel is used. If a diamond electroplated abrasive belt is used It only takes less than an hour to complete all the work, including the installation process to achieve the required effect, which can greatly save time, power consumption and reduce environmental pollution.

Grinding and chamfering of silicon ingots

Before slicing silicon ingots, the surface needs to be ground to remove the cracks caused by etching, which can greatly improve the yield when slicing with a wire saw. All processes can be completed by using a diamond abrasive belt of one grain size, which can realize about three times the high-speed processing of the past, and the surface roughness of Ra 0.07, which is beneficial to the automatic operation in silicon ingot processing.

Ceramic and stone

In order to overcome the weakness of traditional metal valves in poor wear resistance and corrosion resistance, ceramic valves are gradually used. However, the “brittle” and difficult processing of ceramics itself limits its application. With the rise of diamond tools, especially diamond electroplated abrasive belts, The advantages of ceramic valves are more obvious, and the performance is more and more recognized by people in the valve industry. At the same time, a large number of diamond abrasive belts are also used in the surface and edge polishing treatment of marble, granite and other engineered stones.

Due to the strong holding force of the nickel coating on the abrasive, compared with the diamond abrasive, the electroplated CBN abrasive belt can be applied to the grinding and polishing of steel, iron alloy and other difficult-to-machine materials containing iron group elements, especially high carbon steel, alloy steel and quenched steel. Surface grinding and polishing of high-hardness steel materials, as well as occasions requiring automatic control, precision and ultra-precision grinding and polishing.

—EDITOR: Doris Hu

—POST: Doris Hu