Electroplated CMP Pad Conditioner

Dressing polishing pad for semiconductor wafer CMP polishing

Semiconductor CMP process, polishing silicon carbide, Sapphire

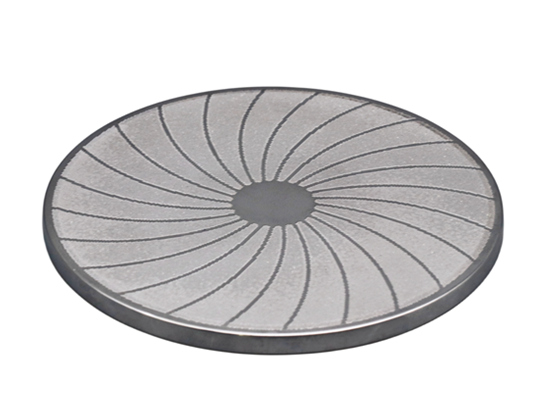

Electroplated CMP Pad Conditioner

Standard size: 4.25″

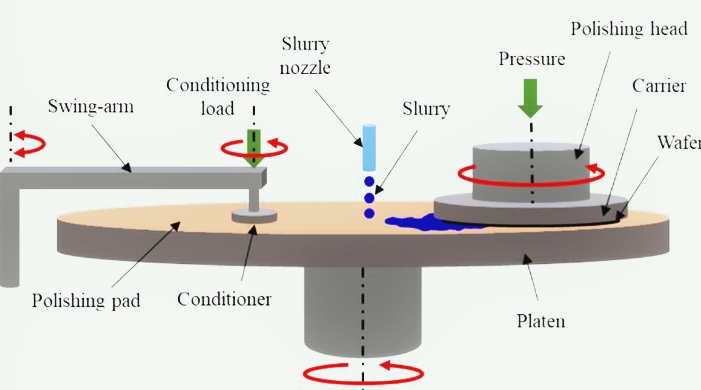

(CMP) is widely used to planarize semiconductor wafers and smooth the wafer surface. In CMP process, CMP diamond pad conditioner is used to dress the polishing pad to restore the pad planarity and surface roughness.

CMP equipment:

CMP is different from the equipment used in the front-end process. It is a mechanical processing equipment, so the process will also be affected by it. The CMP device is similar to a

polishing machine used to mirror-polish the surface of a wafer, and a thinning machine (a device that polishes the backside of the wafer).

1. Wafer support platform (Platen): adsorbs wafers

2. Polishing pad: Grinds the surface of the silicon wafer. Polishing material (Slurry) drips from the polishing pad and grind wafer

3. Polishing compound: A solution of abrasive particles and a specific solvent mixed together

4. Dresser (also called CMP Pad Conditioner): prevents the grinding fluid on the polishing pad from clogging and performs in-situ dressing

During the CMP process, the physical and chemical properties of the polishing pad will change, which is manifested as residual substances on the surface of the polishing pad, the volume and number of micropores are reduced, the surface roughness is reduced, and molecular reorganization occurs on the surface, forming a glaze with a certain thickness. chemical layer, resulting in a reduction in polishing efficiency and polishing quality. Therefore, it is necessary to dress the polishing pad properly, remove the glazed layer on the surface of the polishing pad, and increase the surface roughness of the polishing pad to repair the processing performance of the polishing pad, improve the polishing quality of the wafer, extend the service life of the polishing pad, and reduce polishing costs.

Electroplated CMP Pad Conditioner plays the role of removing waste liquid in the groove of the polishing pad, improving the surface roughness of the polishing pad and improving the flatness of the polishing pad. Therefore, the CMP dresser’s performance directly affects the wafer surface’s global planarization effect.

The CMP dresser should have the characteristics of high material removal rate, diamond abrasive grains that are not easy to fall off, equal height and uniform distribution to ensure that the wafer can achieve qualified global planarization.

What are the applications of CMP dresser?

1. Semiconductor CMP process

2. Silicon wafer polishing process

3. Polishing of third-generation semiconductors such as silicon carbide

4. Sapphire polishing

Features of Electroplated CMP Pad Conditioner:

1. Long life : Utilization of edges by diamond face

2. Excellent disk flatness,can achievesuperior wafer uniformity

3. Clean disk surface, can achievenear zero micro scratches.

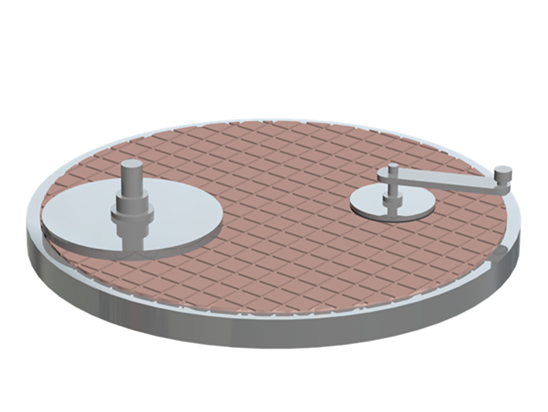

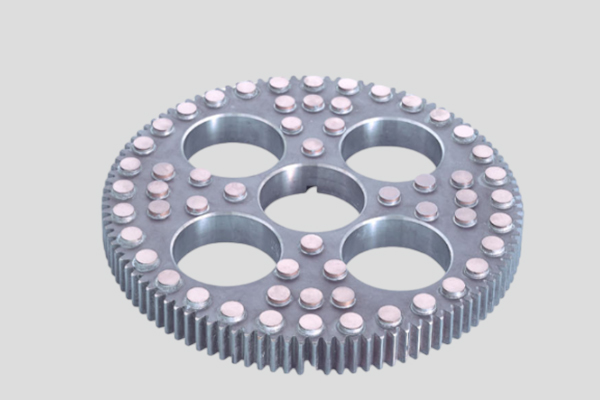

Dressing wheel attached with diamond pellets for dressing polishing pad

The dressing wheel is made of diamond pellets or diamond rings bonded to the base material. The pellets grit ranges from W7 to W40. It is mainly used for polishing the skin of the upper and lower fixed plates of the polishing machine and correcting the grinding stone on the grinding machine. The base material includes various grades of ductile iron, stainless steel, and aluminum parts, and the inner hole form includes round and plum blossom shapes.

Application of dressing wheel with diamond pellets:

Mainly used for dressing cast iron grinding discs, cast iron standard molds, diamond CBN grinding discs, and polishing discs and polishing molds and Polyurethane polishing pad dressing and sharpening.

Features of dressing wheel with diamond pellets:

According to the trimming and sharpening of different materials, diamond pellets with different hardness, different particle size, different porosity, and different coverage ratio are selected. The pellet correction wheel has high hardness, good durability, good trimming surface, no threshing, no scratching of polishing leather, and high correction efficiency.

| Diameter | Thickness | Teeth number | Modulus |

| 104 | 20 | 50 | M2 |

| 143.7 | 20 | 66 | DP12 |

| 144 | 20 | 70 | M2 |

| 232.8 | 25 | 108 | DP12 |

| 232 | 25 | 114 | M2 |

| 315.4 | 25 | 147 | DP12 |

| 390 | 25 | 128 | M3 |

| 432 | 30 | 142 | M3 |

| 427.6 | 30 | 200 | DP12 |

| 516 | 30 | 170 | M3 |

| 558 | 30 | 184 | M3 |

| 627 | 30 | 207 | M3 |

| 720 | 30 | 178 | M4 |

| 760 | 35 | 190 | M4 |

Related Products

-

Back Grinding Wheel for LED Substrate

Back Grinding Wheel for LED Substrate

-

Polyurethane (PU) Polishing Pad for Wafer Surface

Polyurethane (PU) Polishing Pad for Wafer Surface

-

Back Grinding Wheel for Surface Grinding Various Silicon Wafer

Back Grinding Wheel for Surface Grinding Various Silicon Wafer

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.