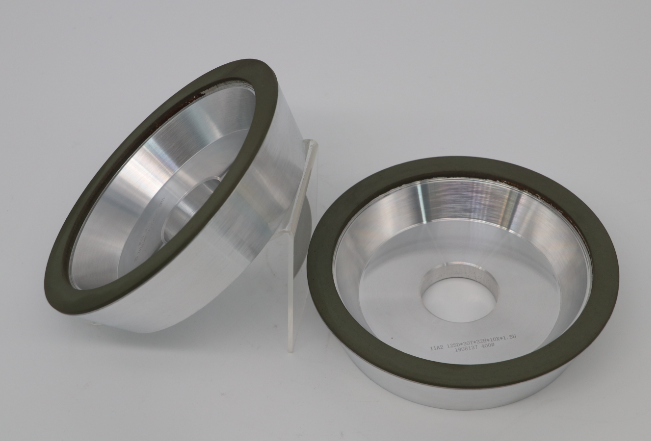

Diamond grinding wheels for sharpening tungsten carbide saw blades

Diamond and cbn wheels for sharpening circular saw blades (TC, HSS)

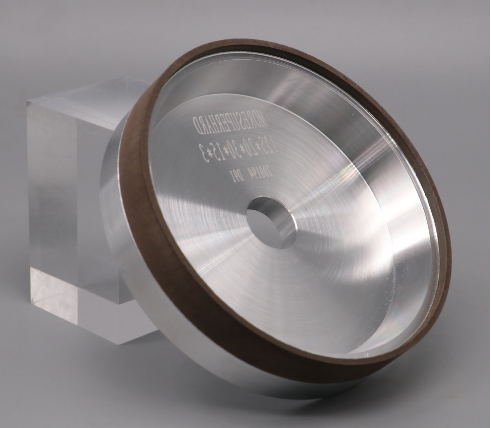

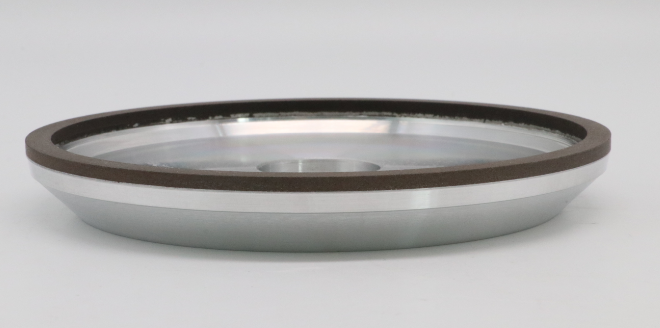

Models of grinding wheel: 1A1W, 3A1, 4A2, 4B1, 4V2,4BT9, 6A2, 6A9, 11V9, 11V2, 12A2, 12D1, 14F1, 15A2, etc.

CNC machines: Vollmer, Woodtronic, Akemat, Widma and so on

Grit size: D46, D64, D76, D91

Application case of Rotary saw Infeed Sharpening

Descriptions of diamond grinding wheel for sharpening tungsten carbide saw blade

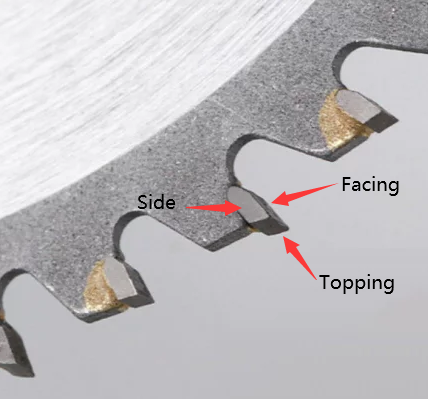

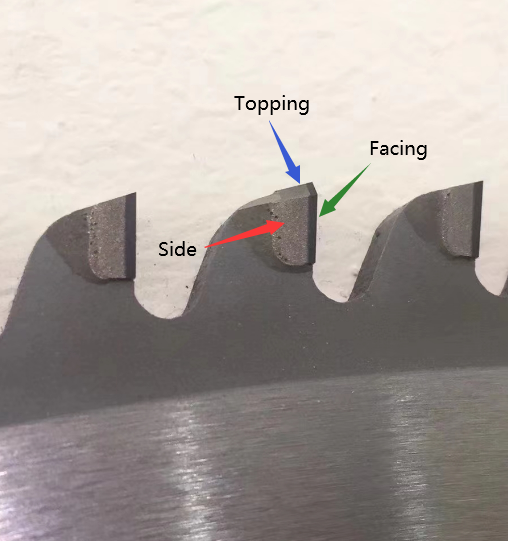

Circular saw blades with tungsten carbide (TC) segments are nowadays commonly used across various industries. Be it during production of a new saw blade, or during a resharpening of a used saw, grinding of the TC segments is a multi-step process and is performed on different machines. Moresuperhard provides diamond and CBN grinding wheels to the saw blade industry. Widely used for face grinding, top grinding, flank grinding, hollow tooth grinding and re-sharpening for tungsten carbide tipped saw blades and one-piece HSS saws.

For top grinding: the grinding wheel needs high efficiency.

For face grinding: needs the grinding wheel to maintain stable quality.

For side grinding, the grinding wheel needs smooth grinding.

Circular saw blades types

– Carbide circular saw blades types

– PCD circular saw blades types.

carbide circular saw blade PCD circular saw blade

What type of grinding wheels for sharpening saw blades

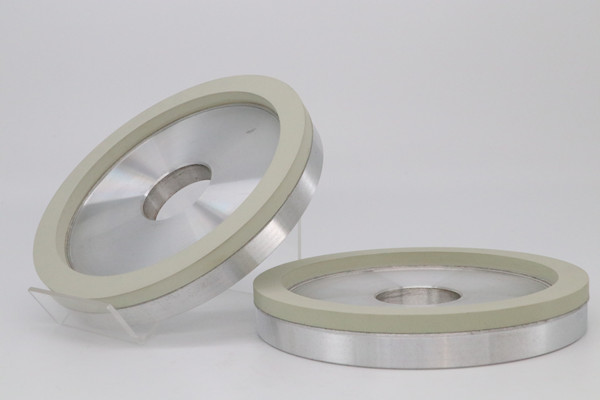

– Resin bond diamond grinding wheel

The bond strength is weaker than other wheels. The self-sharpening for carbide saw blade is better. The low grinding force and grinding temperature . Wear resistance is poor, and the wear of abrasive tools is high and is not suitable for heavy load grinding. Resin bond diamond grinding wheels are used for sharpening carbide saw blades. Resin CBN wheels for hss circular saw tipped.

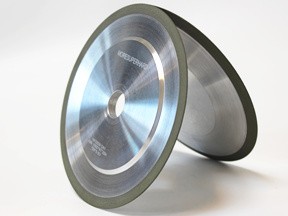

– Vitrified bond diamond grinding wheel

Vitrified diamond wheels for grinding pcd tips saw blades. The wear resistance and bonding strength is higher, and the cutting is sharper and efficiency is higher. It has better control for heating, blocking, thermal expansion and accuracy. But the surface of saw blade after sharpening is rough and the cost is higher.

What are steps in the process of sharpening circular saw blades

- Flank grinding

- Top grinding

- Face grinding

- Hollow tooth grinding and resharpening

Shape and dimensions of the grinding wheels that are used in grinding carbide-tipped saw blades depend on the grinding machine, as well as on the shape of the saw blade itself.

The CNC machines: Vollmer, Woodtronic, Akemat, Widma and so on

| Application | Rotary saw Infeed Sharpening |

| Mterial | HSS |

| Hardness | 65HRC |

| Wheel sizes | 200x6x2x10x32 |

| Grit | B107 C120 |

| Wheel speed | 26m/s |

| Machine | Vollmer |

| Depth of pass | 0,2mm |

| Coolant | DRY |

| Ra | 0.4um |

Applicable grinding machine:

| Machine | Machine type |

| Vollmer Biberach | CB, CC, CE, CEN, CEP, CHC, CHM, CHP, CHT, CNHB, CX and others |

| CHD | |

| CC, CEF, CFL, CHAFT, CHAFTE, CHHF, CHF and others | |

| Vollmer Dornhan | Finimt600 |

| Finima800, Finimax | |

| FinimatBeta, Gamma | |

| Unilapp | |

| UnilappF2 | |

| Duo TS | |

| Woodtronic | NC2, NC3, C4, C5 |

| CNC5 | |

| CNC6F | |

| Akemat | AkematB / B10 |

| AkwmatU / U10 | |

| AkwmatF / F10 | |

| Widma | Unimat |

| HKS700/Hlll | |

| HKS400, FS1000 |

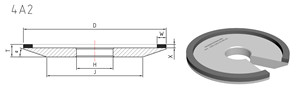

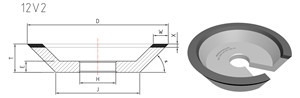

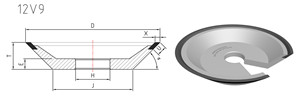

| Saw tooth | Shape | D (mm) | W (mm) | H (mm) | X (mm) | ||

| Face grinding

(4A2, 12V2, 12V9)

|

|

100 | 5 | 25 | 2 | ||

| 125 | 6 | 20 | 4 | ||||

|

125 | 4 | 32 | 2 | |||

| 200 | 4 | 32 | 2 | ||||

|

100 | 2,3 | 25 | 4 | |||

| 125 | 2,3 | 25,32 | 4 | ||||

| 150 | 2,3 | 32 | 4 | ||||

| 200 | 2,3 | 32 | 4 | ||||

| Shape | D (mm) | W (mm) | H (mm) | X (mm) | |||

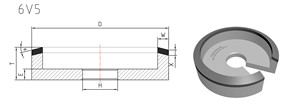

| Top grinding

(6V5, 14M1)

|

|

100 | 5 | 25 | 10 | ||

| 125 | 5 | 32 | 10 | ||||

|

14M1 |

150 | 5 | 32 | 8 | |||

| 200 | 5 | 32 | 8 | ||||

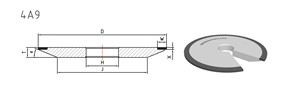

| Saw tooth | Shape | D (mm) | W (mm) | H (mm) | X (mm) | ||

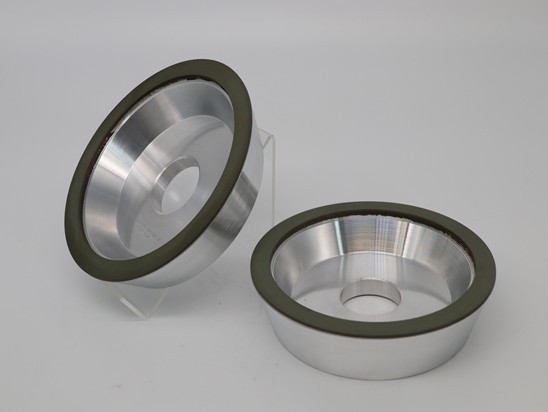

| Flank grinding

(4A9) |

|

80 | 5 | 32 | 4 | ||

| 86 | 5 | 32 | 4 | ||||

| 100 | 4,5 | 32 | 4 | ||||

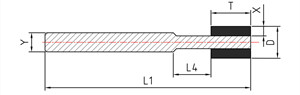

| Shape | D (mm) | T

(mm) |

X

(mm) |

Y

(mm) |

L

(mm) |

||

| Hallow tooth grinding

(1a1w, 1a8)

|

|

6.5 | 3 | 1.75 | 6 | 42 | |

| 7 | 3 | 2 | 6 | 42 | |||

| Should you not find shape & dimensions that you require, do not hesitate to contact us. Email: info@moresuperhard.com | |||||||

Tooth tip grinding wheel

| Size | D | T | U | X | V° | H | Grit | Concentration | Matrix |

| 14M1 | 127 | 8 | 5 | 6 | 8 | 32 | D126 | C100 | A |

| D46 | C75 | ||||||||

| 14M1 | 150 | 10 | 5 | 8 | 8 | 32 | D126 | C100 | A |

| D46 | C75 | ||||||||

| 14M1 | 200 | 10 | 5 | 8 | 8 | 32 | D126 | C100 | A |

| D46 | C75 |

Tooth face grinding

| Size | D | T | W | X | S° | H | Grit | Concentration |

| 12A2 | 150 | 13 | 6 | 2 | 20 | 32 | D46 | C100/125 |

| 12A2 | 150 | 13 | 8 | 2 | 20 | 32 | D76 | C100/125 |

| 12A2 | 150 | 13 | 6 | 2 | 20 | 32 | D46 | C100/125 |

| 12A2 | 150 | 13 | 8 | 2 | 20 | 32 | D76 | C100/125 |

| 12A2 | 150 | 13 | 6 | 2 | 20 | 32 | D46 | C100/125 |

| 12A2 | 150 | 13 | 8 | 2 | 20 | 32 | D76 | C100/125 |

| 12A2 | 150 | 13 | 6 | 2 | 20 | 32 | D46 | C100/125 |

| 12A2 | 150 | 13 | 8 | 2 | 20 | 32 | D76 | C100/125 |

Related Products

-

Diamond Grinding Wheel for Chainsaw Sharpening

Diamond Grinding Wheel for Chainsaw Sharpening

-

CBN grinding wheels for band saw blades

CBN grinding wheels for band saw blades

-

6A2 Diamond Wheel for PCD Saw Blades

6A2 Diamond Wheel for PCD Saw Blades

-

15A2 Diamond Grinding Wheel for Sharpening Carbide Saw

15A2 Diamond Grinding Wheel for Sharpening Carbide Saw

-

11A2 Diamond Grinding Wheel for Sharpening Carbide Saw

11A2 Diamond Grinding Wheel for Sharpening Carbide Saw

-

4B9 Diamond wheels for deep grinding of the cutting face of circular saw blade

4B9 Diamond wheels for deep grinding of the cutting face of circular saw blade

-

4A2 Diamond wheels for the cutting face and the back side of circular saw blades

4A2 Diamond wheels for the cutting face and the back side of circular saw blades

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.