RELATED BLOG

-

Why CBN grinding wheel superior to Diamond wheel in Grinding Nitinol (NiTi)

2026-02-11 -

How to Choose the Right Grinding Wheel for Rubber Grinding

2026-01-29 -

How to Choose the Right Vacuum Brazed Diamond Tool

2025-12-17 -

How to Select the Right Polishing Pad Material for Different Sapphire CMP Stages

2025-12-07 -

Which Grit Wheel Should You Choose for Wood Turning Tools?

2025-12-04 -

Difference Between CVD Diamond Roller Dresser and Electroplated Diamond Roller Dresser

2025-11-18

-

Why Do machine Tools Release Stress?

2020-03-16When the object deforms due to external factors (such as stress, humidity, temperature field changes, etc.), interacting internal forces were caused by each part of the object to resist the effect of such external factors and try to restore the object from the position after deformation to the position before deformation.Learn More

-

What are the characteristics of glass grinding

2020-03-14The glass is wind-proof, light-permeable, stable in performance, various types have different characteristics due to the use of different occasions, the scope of application is very wide. When we are choosing glass, besides paying attention to price, still answer its kind and performance to have certain understanding, make full use of strong points to avoid weak points, just can find the material that suits to use more.Learn More

-

Grinding Wheel for processing Spring

2020-03-14The grinding wheel for processing spring is a kind of abrasive tools with resin as a binding agent. Because the components being processed are special spring steel with high hardness and high quenching degree. If the hardness of the grinding wheel is low, it will easy to break, Poor safety, and fast wear. If the hardness of grinding wheel is high, although the grinding wheel is not easy to break, but easy to burn the workpiece, affecting the quality of the workpiece.

Learn More

-

How to achieve mirror grinding with grinding wheel

2020-03-13When mirror polishing, first use the vitrified bond diamond grinding wheel with grit 60# or less, make the grinding grains on the surface of the grinding wheel form many semi-blunt micro edges of equal height, when grinding only cut off the micro chip and the surface roughness reaches Ra0.08 ~ 0.04mm.

Learn More

-

Ultra-thin Diamond Cutting Wheel

2020-03-13Cutting hard alloy and zirconia ceramics are very challenging work, first of all, hard alloy often used as a tool, can see the hardness of the high, the same zirconia ceramics Mohr hardness of 8.5, monoclinic crystal density of 5.85, with a very high toughness and hardness, ordinary resin cutting pieces can not be processed.Learn More

-

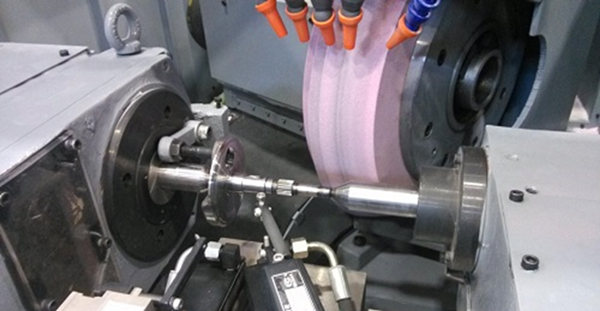

CNC dressing technique

2020-03-09The CNC dressing technique can be used in all fields of grinding production, especially for small and medium production lot sizes and for prototype applications. The profile of the grinding wheel is created by the CNC controlled process that moves the rotating form roll along the target contour. Form rolls are therefore not restricted to a specific workpiece but can be used flexibly.Learn More

-

Honing technology principle

2020-03-06Honing can only change the shape accuracy of the processed workpiece. Some necessary measures should be taken to change the position accuracy of the part.If use the panel to improve the verticality of the end face of the part and the axis (the panel is installed on the stroke arm, adjust it to be perpendicular to the rotating spindle, the part can be processed by leaning on the panel).

Learn More

-

The Features of CBN

2020-03-06The hardness of CBN is higher than that of ordinary abrasive. High hardness means stronger and sharper cutting ability; CBN has high wear resistance, meaning it is more difficult to wear than ordinary abrasives; The ability to maintain the shape of abrasive grains is one of the main characteristics of CBN as a high performance abrasive. CBN has a high compressive strength, which means it can keep particles intact and not easily broken when used in harsh conditions. CBN has good thermal conductivity and can realize cold cutting in grinding.Learn More

-

How to use diamond grinding wheel to grind R0.01 radius on a PCD tool tip?

2020-03-05Moresuperhard has devoted to PCD grinding, cutting, brazing Solutions for many years, and PCD grinding wheels have been widely used in MYTECH,Farman,Corborn, ANCA, Ewag and other PCD grinding machines.Learn More

-

How to Dress Vitrified CBN wheels?

2020-03-04The dressing of CBN grinding wheel can be divided into two steps: Truing and Dressing. Truing is to make the grinding wheel reach the required geometric shape and dimensional accuracy by changing its macroscopic shape of the grinding wheel, and make the grinding wheel tip finely broken to form a sharp grinding edge; Dressing is to remove the binder between the grinding grains of the grinding wheel, so that the grinding grains protrude from the surface of the binder, forming the necessary chip space so that the grinding wheel has the best grinding capacity. According to the specific situation, shaping and sharpening can be unified or completed at the same time, also can be done step by step.

Learn More