How to choose the dicing blade In the substrate processing?

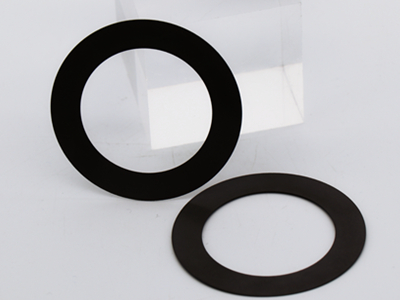

In semiconductor manufacturing, substrate dicing is one of the most critical processes. It refers to the precise cutting of wafers, substrates, or other hard and brittle materials into individual chips or dies. As devices get smaller and substrate materials more diverse—ranging from silicon and sapphire to ceramics, quartz, and composite laminates—the requirements on dicing technology become increasingly demanding.

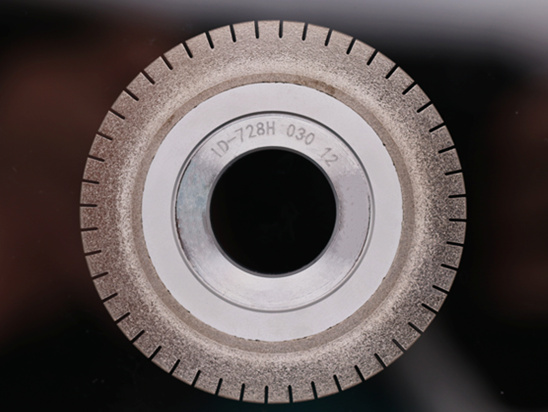

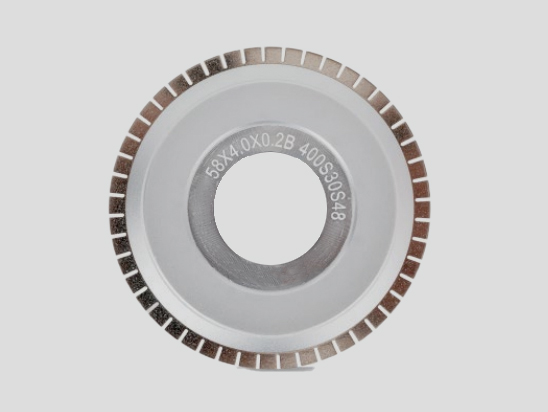

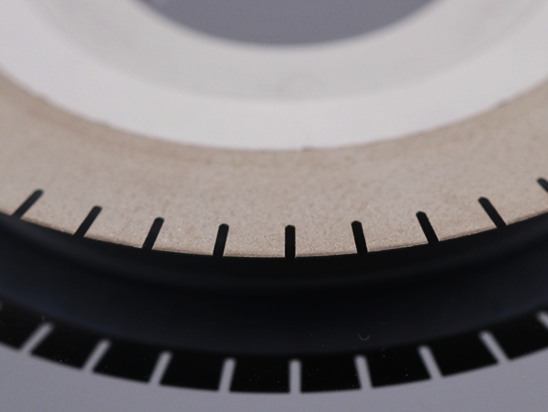

Diamond dicing blade consists of three main elements: diamond grit size, density, and bonding material. Diamond grit acts as an abrasive during wafer dicing and is typically synthesized from CBN (Cubic Boron Nitride). Diamond grit sizes range from 2 to 8 microns. Angular diamond grit is often used to achieve better cutting quality. Diamond grit density represents the ratio of diamond grit to the volume of the diamond blade. Dicing blade suppliers typically offer different diamond grit densities to suit different applications. Nickel metal is used as a bonding agent to hold the diamond grit together.

At the heart of this process lies the dicing blade, a precision-engineered tool that directly influences kerf width, chipping, edge quality, and yield. Choosing the right dicing blade is not merely about selecting a sharp tool; it requires a deep understanding of the substrate material, blade specifications, bond type, grit size, and machine parameters.

Selection factors

Workpiece character: Hardness, brittleness, thermal conductivity, ease of chip removal;

Dicing Blade binders: resin, metal binder

Compatibility and cooling system: clamping method, cooling medium, feed mode.

Selection strategy for different workpiece

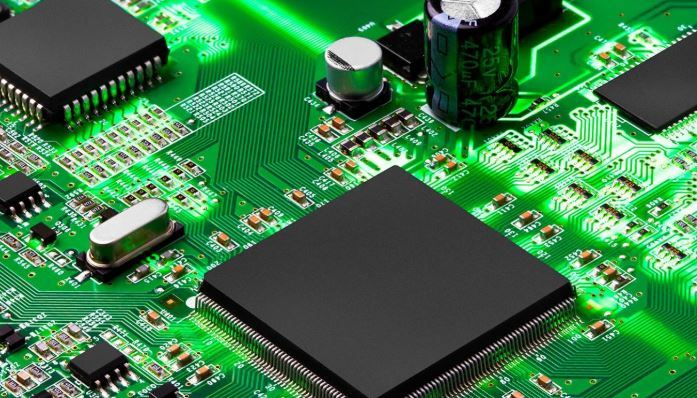

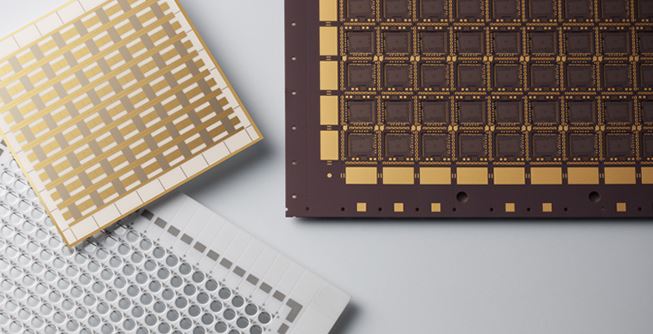

PCB substrate (FR-4/BT resin)

Since PCB contains glass fibers, impact damage is likely to occur during cutting. The best choice is a resin bond diamond dicing blade, whose elastic abrasive grains can effectively reduce impact, minimize cracks and burrs. The recommended grit range is #600 to #800, and the blade thickness should be controlled at 0.1 to 0.3mm.

Copper and Copper Foil Substrates

Copper has strong ductility and the cutting tools are prone to detachment during processing. Metal-bonded diamond dicing blade are required, which have high holding power and can ensure the stable operation of the diamond. At the same time, a SDS coating is used to improve the chip removal ability. The recommended grit size is #200 to #400, and a forced internal cooling design is adopted. The coolant can be water-based emulsion with rust inhibitor.

Ceramic Substrates (Al₂O₃/AlN)

Ceramic substrates, with their excellent electrical insulation, high thermal conductivity, high reliability, and low thermal expansion coefficient, have become a fundamental material for high-power electronic structure and interconnect technologies. However, due to the inherent hardness and brittleness of ceramic materials, processing through-holes and dicing is extremely difficult.

A dicing knife uses a blade to physically cut ceramic substrates. Dicing blades are typically made of synthetic resin, copper, tin, nickel, and other materials bonded to artificial diamond. During cutting, the spindle drives the blade to rotate at high speed, achieving high rigidity and removing material.

Ceramics are brittle and have poor thermal conductivity, during cutting, ceramics are prone to heat accumulation and chipping. Ultra-fine grit diamond tools (≥#1500) should be used, and the pulse cutting mode should be combined. Intermittent feed is adopted to reduce heat accumulation. The coolant is recommended to be deionized water mixed with a low-foaming additive. Ultra-high-density metal bond diamond dicing blade is best choice for dicing cermaic substrate.

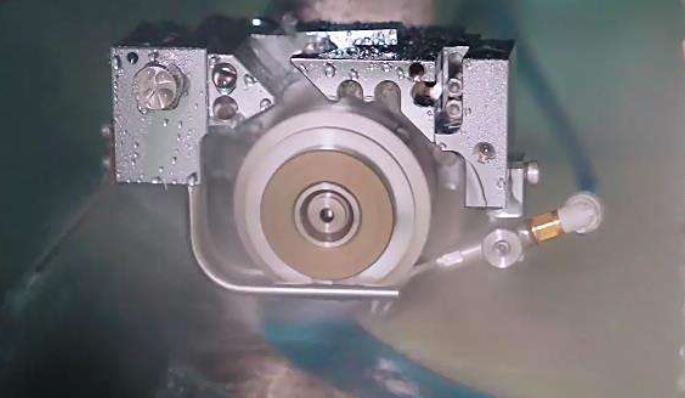

III. Key Points for Equipment Adaptation (DISCO as Example)

Clamping System: Standard vacuum suction cups can be used for PCB/copper substrates, while soft polymer suction cups are required for ceramic substrates to reduce stress concentration.

Cooling Scheme: Pure water cooling is suitable for PCB, emulsified liquid is suitable for copper substrates, and deionized water is recommended for ceramics.

Process Restricted Areas: Avoid excessive feed speed and excessive cutting depth to prevent damage to the blade lifespan.

- PCB → Resin binder + Medium grain size (#600 – #800), thin edge (0.1 – 0.3mm);

- Copper → Metal binder + Coarse grain size (#200 – #400), combined with forced internal cooling;

- Ceramic → Ultra-high density metal binder + Ultra-fine grain size (#1500 – #2000), extremely low feed rate.

—EDITOR: Doris Hu, Anna Wang

—POST: Doris Hu