Polishing film for thermal spray coating

Resin diamond polishing film

Alumina/ Silicon carbide lapping film

For carbides, ceramics, metals, glass, composites, exotic alloys, fiber optic connectors and other material finishing and lapping

Durable, Smooth polishing, Consistent finish performance

Grit: 0.5-80 micro

High-precision polishing film roll is made of micron, sub-micron or nanoscale grinding powder (diamond, silicon carbide, alumina, etc.) and new polymer adhesive materials evenly dispersed, coated on the surface of high strengt film, which widely used in alloy, ceramics, metals, composites and other hard materials area polishing.

Resin Diamond Polishing Film is a product with diamond micron-graded grains slurry coated on high precision 75 µm / 3 mil film, which gives a high-accuracy finishing and excellent flexibility and durability.

The abrasive of polishing film including aluminum oxide, silicon carbide and diamond etc. Different abrasive is to meet different hardness of workpiece finishing requirments, rhe surface polishing quality of diamond polishing film is better than conventional abrasive polishing film.

Applications of resin diamond polishing film

Diamond polishing film used for polishing hard materials likes carbides, ceramics, metals, glass, composites, exotic alloys, fiber optic connectors and other finishing and lapping process.

For roll industry< resin diamond polishing film can be used for super finishing of Chilled Cast Iron Roll, Calender Eco Nip Roll (Rubber) and MicroRock Roll.

* Paper mill: rubber roller (rubber is divided into ordinary rubber, polyurethane rubber, polyurethane high hardness) with silicon carbide suitable, alumina is rarely used.

* Optical communication industry: Polishing and polishing of all kinds of optical fiber connectors and optical fiber devices.

* Precision polishing of optical glass, crystal and LCD substrat

* Steel rod need diamond polishing fim to polish.

* Magnetic head, computer hard disk surface grinding polishing

* Surface polishing and repair of car paintwork and high-grade furniture;

* Grinding and polishing in metallographic analysis of metals and alloys, ceramics, glass, etc

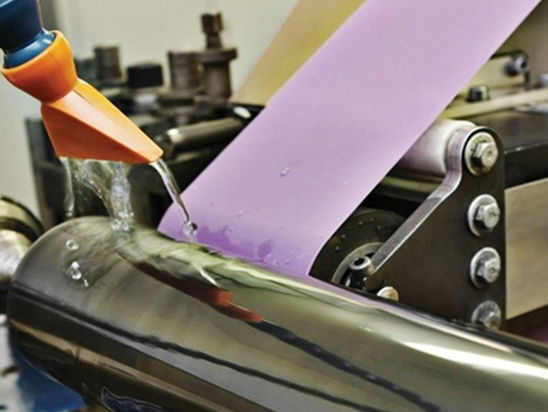

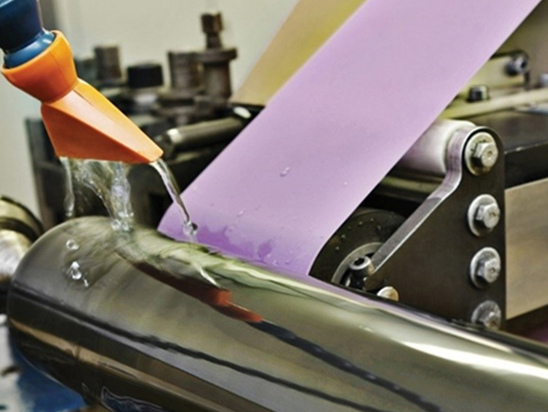

*Super Finishing of Chilled Cast Iron Roll, Calender Eco Nip Roll (Rubber), MicroRock Roll

Moresuperhard resin diamond polishing film can achieve consistency and control for finishing,semi-finish and polishing hard-to-grind materials such as carbide, ceramics, hardened metals, exotic alloys and composites.

Features of resin diamond polishing film

* Durable with high polishing capability

* Provides smooth polishing without deep scratches

* High removal rate with well-plated abrasive grains

* Easy scraping and less plug

* Consistent finish performance with uniform PET backing and abrasive plated-upon

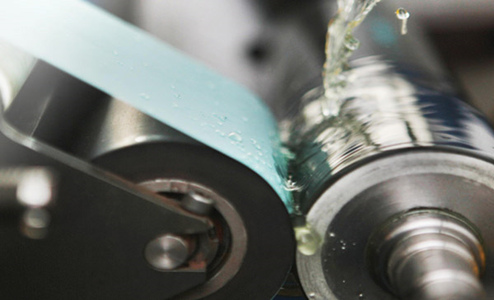

* Dry wet polishing

Moresuperhard offers coarse to fine grit Diamond Polishing Films for thermal spray coating polishing process and a high quality finish for optimised fibre optic network performance.

Difference between electrostatic process of sand and coated belt:

Electrostatic sand method:

Electrostatic sand method refers to the use of high voltage electrostatic field, relying on the electrical properties of abrasive, abrasive becomes charged body and is adsorbed on the base material coated with binder, forming a sand belt with excellent grinding performance.

Features of Electrostatic sand:

Abrasive Angle point up, sharp, high efficiency and long life, electrostatic planting sand belt can be used for all kinds of metal roller, rubber roller polishing, and automobile manufacturing industry: there are mainly two parts: one is the body processing, the second is the final polishing crankshaft, camshaft.

Coated belt:

The surface surface is delicate, and the abrasive and glue are mixed together and coated to the belt.

| Type | Grit | Specification | Base material |

|

Diamond lapping film

|

80μm- 180# |

101.6mm *15m 101.6mm*45m 203mm*15m 20 3mm*45m 101.6mm*15m |

PET |

| 60μm – 240# | |||

| 45μm- 360# | |||

| 30μm- 600# | |||

| 15μm- 1200# | |||

| 9μm- 2000# | |||

| 6μm- 2500# | |||

| 3μm- 4000# | |||

|

Other Sizes Can Be Customize |

|||

| Type | Grit | Specification | Base material |

|

Alumina Lapping film

|

40μm |

10mm*91m 16mm*183m 17mm*183m |

PET |

| 30μm | |||

| 20μm | |||

| 12μm | |||

| 9μm | |||

| 6μm | |||

| 3μm | |||

| 1μm | |||

| Other Sizes Can Be Customize | |||

| Type | Grit | Specification | Base material |

|

Silicon carbide lapping film |

30μm |

50mm*46m |

PET |

| 15μm | |||

| 9μm | |||

| 6μm | |||

| 3μm | |||

| 1μm | |||

| Other Sizes Can Be Customize | |||

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.