Diamond and CBN tools for Hydraulic industry

Moresuperhard diamond and CBN tools for Hydraulic industry:

-Double disc diamond/CBN grinding wheel

-Superhard Materials Grinding Wheels for Slot

Diamond/CBN Honing tools:

-Diamond/CBN honing stick

-Diamond/CBN honing reamer

Internal grinding wheel for inner hole grinding

Moresuperhard can provide completed grinding and honing solutions for hydraulic industry.

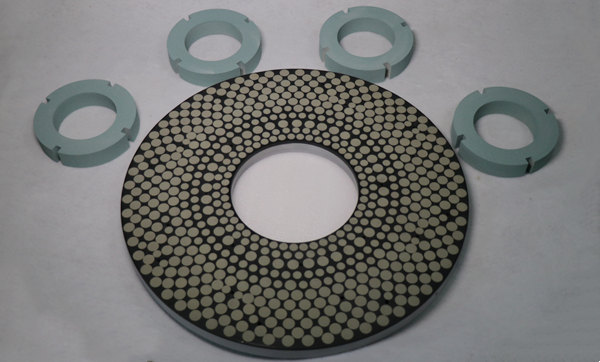

Precision vitrified CBN double disc grinding wheel

Application of vitrified CBN double disc grinding wheel

Double disc CBN grinding wheel is mainly used for grinding platness of parts, suitable for steel, copper, hard alloy, ceramic, monocrystalline silicon processing, be widely used for hydraulic pneumatic components, hydraulic motor parts, high-precision bearing ring and roller, seals, piston rings, cutting tools, molds, instruments, carbide blades, ceramic spool, magnetic materials and other products of double-sided grinding processing.

The hardness of CBN grinding wheel is higher than that of ordinary abrasive, and the cutting ability is stronger and sharper, with good wear resistance and thermal conductivity. The ability to maintain the shape of the abrasive particles is one of the main characteristics of CBN as a high performance abrasive.

The high compressive strength of the CBN grinding wheel on the double-sided grinding machine equipment means that the grain can be kept intact and not easily broken when used under harsh conditions.

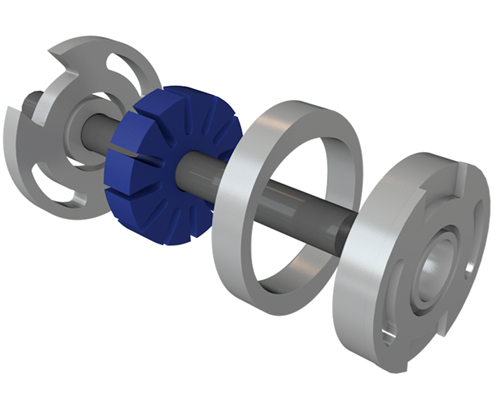

Superhard Materials Grinding Wheels for Slot

Vitrified bond CBN Groove Grinding wheels is suitable for rotary vane compressor, steering pump, vane pump rotor groove grinding, drive shaft grooving and other industries and after grooving molding grinding.

Application

Mainly used for the precise grinding of steering pump rotor slot, gear shaft groove, bearing groove.

Applied material

Mainly used for cutting and fine grinding of sealing components and hydraulic parts.

Diamond/CBN Honing tools

Hydraulic and pneumatic industry segment is one of the most renowned area for the use of the honing process. Functionally optimized surfaces ensure high precision of components.

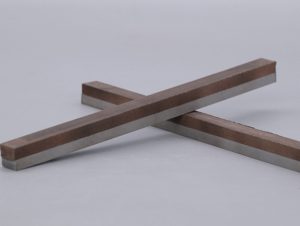

Diamond/CBN honing stick

Honing is the precision machining process in which a very fine surface on a workpiece is produced using an abrasive tool.

Diamond honing stick is mainly used for fine grinding of automobile, diesel engine, motorcycle, tractor engine pump body, hydraulic cylinder chamber, hydraulic pump inner hole, cylinder block, valve, cylinder nozzle, compressor cylinder hole spline hole inner surface and other series of cylinder hole and blind hole.

Diamond honing stick is a kind of diamond honing tool which sintered fine diamond particles and metal powders together by powder metallurgy process. It is mainly used for honing the inner hole of engine cylinder block and connecting rod of automobile and tractor. It can also be used for honing the inner hole of gear hydraulic parts, etc. Besides cast iron and steel parts, honing materials can also be broken steel parts, hard chrome plated parts and ceramics, etc

Honing hydraulic cylinders

The processing of prepared holes is highly significant for the honing process of hydraulic and engine cylinder surfaces, for which ultrahigh precision is required.

High quality honing of hydraulic cylinders is essential, as the effective operation of the pistons depends on the cylinder having a very fine surface finish, which can also prevent premature wear of moving components. Honing also creates a secure seal around a hydraulic cylinder, providing extended life and preventing costly leaks.

Single stroke honing is also called sequential honing or diamond hinge honing tool, it is a new process of micron precision machining, diamond honing reamer can process through hole, blind hole, keyway hole, step hole and other hole.

Moresuperhard diamond/CBN honing reamer for hydraulic cylinders

Application of diamond honing reamer: single-stroke honing technology has been adopted in automobile, tractor, power machinery, construction machinery, refrigeration machinery and aerospace industry.

Case of single pass diamond honing reamer for honing hydraulic Cylinders

| Workpiece | Hydraulic cylinder |

| Workpiece material | 20MnCr5 |

| Workpiece hardness | 58-62 HRC |

| Size accuracy | ±0.005 |

| Processing allowance | 40μm |

| Surface finish requirement | Ra0.2 |

Related Products

-

Single Pass Diamond Honing Tools, Electroplated Diamond Reamers

Single Pass Diamond Honing Tools, Electroplated Diamond Reamers

-

Single Stroke Diamond Honing Reamer

Single Stroke Diamond Honing Reamer

-

Cylinder honing head, diamond honing heads

Cylinder honing head, diamond honing heads

-

Diamond Honing Tools for Thermal Spraying Coatings in Cylinder Bores

Diamond Honing Tools for Thermal Spraying Coatings in Cylinder Bores

-

Vitrified bond CBN Groove Grinding wheels is suitable for rotary vane compressor, steering pump, vane pump rotor groove grinding, drive shaft grooving

Vitrified CBN Grinding Wheel for Rotor Slot

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.