Diamond Sanding Abrasive Belts for Thermal Spraying Coatings

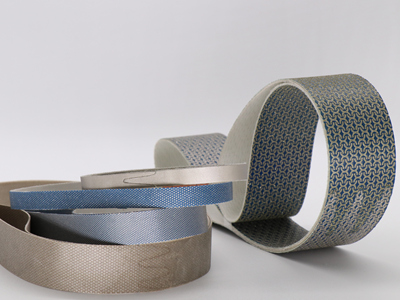

Diamond cbn sanding belts / Flexible belts

Polishing, grinding steel, stone, glass, ceramics, mono crystalline silicon, polysilicon, zirconia, alumina, metal-nonmetallic synthetic materials, cemented carbide, aluminum magnesium alloy, aluminum beryllium alloy, titanium alloy and etc. hard brittle materials.

Bond: Metal nickel plating electroplated bond, Resin bond ( resin bond also consists of flexible and hard type)

Length: 150mm – 5000mm

Width: 5mm – 350mm

Grit: #60,#100,#120,#200,#400,#800,#1500,#2000,#3000,#5000

Applications of diamond and cbn sanding belts

Diamond cbn sanding abrasive belt can be widely used for grinding steel, stone, glass, ceramics, mono crystalline silicon, polysilicon, zirconia, alumina, metal-nonmetallic synthetic materials, cemented carbide, aluminum magnesium alloy, aluminum beryllium alloy, titanium alloy and etc. hard brittle materials.

► Electroplated Bond Diamond Sanding Abrasive Belt

► Resin Bond Diamond Sanding Abrasive Belt

Electroplated dimond emery strips

The size of diamond emery strip is longer than conventional sanding belt, both sides need to leave extra uncoated dimensions for import and export. Electroplated diamond emery strips are used to solve the difficult-to-grind materials such as stones, glass, ceramics, metals, carbides and composites.The sharp-cut diamond minerals and flexible backing make this abrasive a good match for use in a variety of metal processing applications .

Specificatiion of Electroplated diamond emery strips

| Width | 50, 75,100,150,200,rtc |

| Length: | 3200/1200,4000/2000,6000/4000,etc |

| Grit | 60 ,120, 400, 800, 1200, 1500 |

| Other specification can customize | |

Features of Diamond emery strips

* More embedding depth, less exposure

* Grinding belt does not move parts

* Shortcomings: diamond particles are easy to fall off, do not require grinding allowance.

* Wet grinding effect is good

| Length | Width | Girt | ||

| (mm) | (inch) | (mm) | (inch) | #60,#100,#120, #200, #400, #800, #1500, #2000, #3000, #5000 |

| 150 – 5000 | 6” – 200” | 5 – 350 | 1/5 “ – 14” | |

Example Parameters of diamond sanding belts for HVOF WC coating

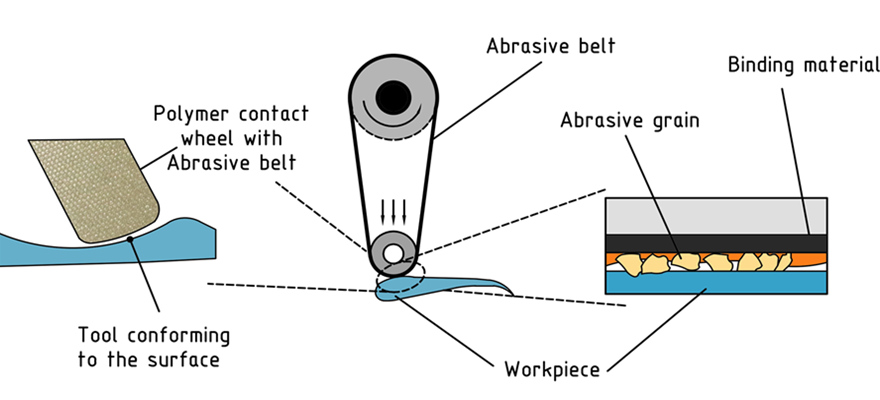

Diamond sanding abrasive belt is a kind of coated abrasive tool, which is superhard material (synthetic diamond) abrasive particles adhesive to the flexible base by bond. And can be divided into metal nickel plating electroplated bond and resin bond, resin bond also consists flexible and hard type. In some sense The grinding by diamond sanding belt for thermal spray coating industry can replace that of diamond grinding wheel and film polishing. Diamond sanding belt can complete the grinding and polishing process. Recently, it is widely used in thermal spray coating industry, the production and repair of hydraulic cylinder and turbine blade.

| Workpiece diameter | 400mm*12 HVOF spraying |

| Grinding machine model | 65656 |

| Belt speed | 22 m/s (2800rpm) |

| Belt contact workpiece mode | soft contact or hard contact |

| Workpiece rotation speed | 30 RPM |

| Coolant | water or others |

| Spray coating thickness | 250μm |

| Original roughness of spray coating | Ra 0.4mm-0.6mm |

| Machining allowance of spray coating | 100μm |

| Coating thickness after processing | 150μm |

Case of resin diamond sand belt for steel cutting tool

| Workpiece | Steel knife |

| Moresuperhard CBN sanding belt | 50x1500mm 4000#

50x1500mm 800# |

| First test (50x1500mm 4000#) | The belt is little bit too stiff for small belt grinder, but work well and customer satisfy with surface finish |

| Second test (50x1500mm 800#) | It is thinner and much flexible than 4000# |

Case of resin diamond sand belt for HVOF coating

| Workpiece | HVOF coating |

| Moresuperhard resin diamond sanding belt | 50mmx915mm 1500# |

| Surafce finish | After polishing, Ra 0.05-0.09 |

| Bond | Resin bond and electroplated bond diamond polishing belts |

| Size | 50x1200mm |

| Dry/wet polishing | Wet polishing |

| Workpiece

|

Ceramics, Al2O3 based, TiO2 based, Y2O3 based, Cr2O3 based, ZrO2 based.

Cr2O3 99,2 Other 0,8% max from paper industry; Chrome carbide ,tungsten carbides,stainless steel 410 -420 series; Nickel Silicon Boron based Wire with >50% Fused Tungsten Carbide (FTC). The coating results in a hard nickel backed matrix (540 HV0,1) with hard FTC particles (2400 HV0.1). |

| Workpiece diameter | 200-800mm |

Related Products

-

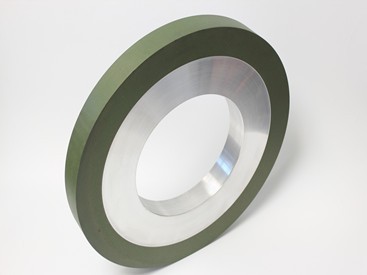

Diamond Cylindrical Grinding Wheel for HVOF Thermal Spraying Coatings

Diamond Cylindrical Grinding Wheel for HVOF Thermal Spraying Coatings

-

Diamond Sanding Abrasive Belts for Thermal Spraying Coatings

Diamond Sanding Abrasive Belts for Thermal Spraying Coatings

-

Diamond Honing Tools for Thermal Spraying Coatings in Cylinder Bores

Diamond Honing Tools for Thermal Spraying Coatings in Cylinder Bores

-

vitrified diamond grinding wheel used in thermal spraying coating

Vitrified Diamond Grinding Wheel for Hard Surface in Thermal Spraying Coating

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.