How a Novel Large-Pore Resin Bond Diamond Wheel Solves Rubber Roll Grinding Challenges

1. The Real Grinding Problem in Rubber Roll Applications: Why Polyurethane is Particularly Tricky

Unlike grinding metals or rigid materials, grinding rubber rolls, especially Polyurethane (PU) rubber rolls, presents a fundamentally different set of challenges.

According to this application case, the customer required a fine-grit (200#) resin bond diamond grinding wheel to achieve a high surface finish suitable for precision equipment assemblies.

However, polyurethane rubber exhibits three characteristics unfavorable for grinding:

* Soft material structure

* Strong elasticity

* Sticky grinding debris

These properties directly impact grinding stability and surface quality, often rendering traditional grinding methods insufficient.

Why Fine-Grit Resin Diamond Wheels Alone Are Not Enough

In theory, a 200# fine-grit resin diamond wheel is typically designed to improve surface smoothness. However, in practice, this case revealed a critical contradiction.

During the grinding process:

* Fine polyurethane debris was continuously generated.

* The small spacing between fine abrasive grains hindered effective chip evacuation.

* Sticky debris adhered to both abrasive grains and bond bridges.

As grinding continued, this inevitably led to wheel loading (clogging), resulting in:

* Loss of effective cutting edges

* Increased friction rather than efficient material removal

* Scratches and adhesion marks on the rubber roll surface

* Reduced grinding efficiency and inconsistent quality

During trial production, the surface roughness of the rubber roller briefly reached the expected level during the initial grinding with the Moresuperhard large-pore resin-bonded diamond grinding wheel. However, as grinding continued, the chip removal problem of the fine-grained grinding wheel became increasingly prominent, leading to significant clogging of the grinding wheel. This resulted in scratches and adhesion marks on the rubber roller surface, failing to meet the precision requirements.

The clogging problem was subsequently resolved by adjusting grit-size parameters and optimizing the pore structure of the large-pore resin-bonded diamond grinding wheel. This validated the critical need to prioritize chip removal performance when using fine-grained grinding wheels in the grinding of polyurethane rubber rollers.

Root Cause Identified in the Case Study: The Conflict Between Fine Grit and Chip Evacuation Capacity

This case study clearly demonstrates that the grinding failure was not solely caused by abrasive grit size selection.

The real problem stemmed from:

The incompatibility between the inherent density of fine grit and the suboptimal chip evacuation capabilities of conventional resin bond structures when grinding sticky rubber materials.

In other words:

* Surface finish requirements demanded fine grit.

* Rubber grinding conditions required robust chip evacuation.

* Conventional resin bond wheels struggled to simultaneously meet both demands.

This conflict represented the key technical bottleneck in rubber roll grinding.

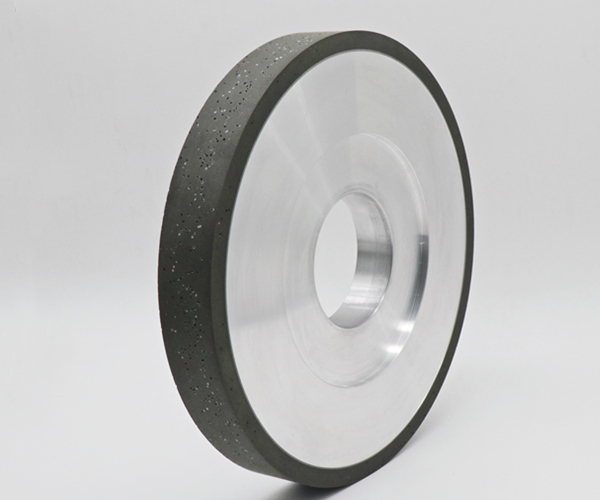

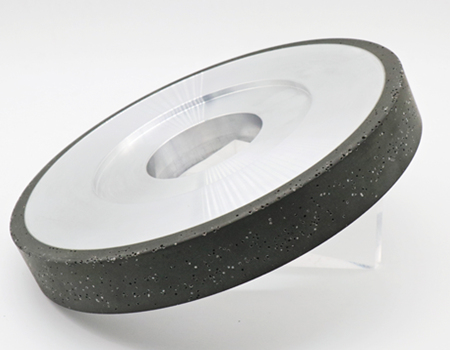

New Formula Solution: Large-Pore Resin Bond Diamond Wheel Design For Rubber Roll

To address this specific problem, the grinding wheel formulation underwent an innovative modification.

Structural Innovation Based on the Case

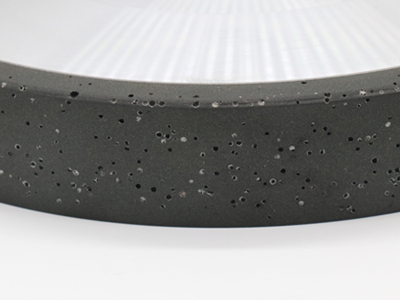

A pore-forming agent was introduced into the resin bond system, thereby creating a large-pore wheel structure.

This design change directly targeted the root causes identified during grinding:

* Larger internal pores provided ample space for sticky rubber debris.

* Improved chip evacuation effectively prevented debris accumulation.

* Reduced contact area lowered grinding heat generation.

* Abrasive grains remained exposed and actively cutting.

The focus of this solution was on optimizing the wheel structure to adapt to rubber grinding characteristics, rather than simply changing the abrasive type.

Why the Novel Formula Resin Bond Wheel Works for Rubber Rolls

Strictly based on this case, the advantages of the novel large-pore resin bond diamond wheel can be summarized as follows:

* Resolves the contradiction between fine grit and chip evacuation efficiency.

* Maintains effective cutting action, preventing the smearing of rubber material.

* Reduces thermal accumulation during grinding.

* Ensures consistent surface quality under continuous operation.

These advantages are not merely theoretical derivations; they are directly observed and confirmed through the grinding performance in this rubber roll application.