How to Polishing Crankshaft/Camshaft

1. What is Crankshaft

The crankshaft making by carbon structural steel or ductile iron which mainly composed of the main journal, connecting rod journal, crank, balance block, front section and rear end, etc..

The produce processing is: blank → punching → CNC processing → rough grinding → polishing.

2. What is Camshaft?

The camshaft character is poor rigidity, easy deformation; but with high precision, difficult processing. The mainly processing are: blank → CNC lathe → CNC milling machine → deburring → quenching and tempering → straightening → fine grinding of cam → fine grinding of support shaft diameter → polishing with sand belt.

Application of Crankshaft and Camshaft

Crankshafts and camshafts are key components in:

-

Automobile engines (petrol and diesel)

-

Motorcycles

-

Heavy machinery

-

Marine engines

-

Power generation equipment

Their performance directly affects engine efficiency, fuel consumption, and emissions.

Why need polishing crankshaft/camshaft?;

The crankshaft and camshaft need to be polished to reduce friction, enhance lubrication, minimize wear, extend service life, and ensure the normal and efficient operation of the engine. The surface is smoother, which can better maintain the lubricating oil film, reduce direct contact between metals, thereby lowering friction resistance and improving the efficiency of the engine.

How to polishing crankshaft/camshaft ?

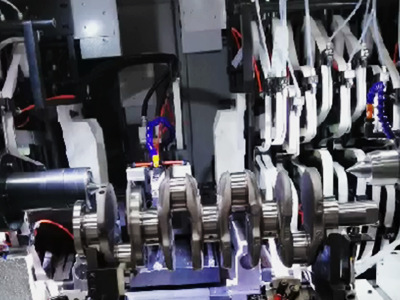

The traditional process is using oilstone to super-finishing, which will damages the geometry of the journal and has a great impact on the journal size. The super-finishing of crankshafts has long been done by CNC belt polishing.

How to Polish a Crankshaft?

Polishing a crankshaft typically involves:

-

Initial Grinding: Removes major surface imperfections and ensures roundness.

-

Polishing: Fine abrasives (like polishing films) are used on a polishing belt machine to improve the surface finish.

-

Inspection: Surface roughness (Ra) is measured, typically aiming for values below 0.2 µm.

The polishing film used should be flexible yet durable, often with micron-graded aluminum oxide or diamond abrasives, depending on the material and required finish.

How to Polish a Camshaft?

Camshaft polishing requires similar steps:

-

Grinding: Reshapes the lobes and journals.

-

Polishing: A flexible polishing film is applied to bring the surface roughness down, especially on the lobes.

-

Balancing and Inspection: Ensures proper valve timing and wear resistance.

Polishing Film

Polishing film is a high-precision abrasive product made by coating micron-graded abrasive particles (such as diamond, aluminum oxide, or silicon carbide) onto a polyester film backing. It is engineered for fine finishing, surface correction, and micro-level polishing of materials that require tight tolerances and high surface quality.

Key Features of Polishing Film:

-

Uniform Abrasive Coating: Ensures consistent performance and finish quality.

-

Precision Grading: Available in very fine grits (typically from 0.1 to 60 microns).

-

Durable Backing: Polyester film offers excellent flexibility and dimensional stability.

-

Versatile Formats: Available in sheets, discs, rolls, or customized forms.

Common Abrasives Used:

-

Diamond – for hard materials like ceramics, carbide, sapphire, and hardened steel.

-

Aluminum oxide – for metals, plastics, and softer substrates.

-

Silicon carbide – for glass, stone, and non-ferrous materials.

Applications of polishing film:

-

Polishing optical components

-

Finishing semiconductor wafers

-

Polishing engine parts like crankshafts and camshafts

-

Fiber optic connector end-face polishing

-

Lapping and precision finishing in electronics and aerospace

Advantages of Polishing Film for Crankshaft and Camshaft

-

-Consistent Finish: Offers uniform abrasive particle distribution for repeatable results.

-

-Precision: Micron-level control over surface roughness.

-

-Efficiency: Faster processing time than traditional abrasives.

-

-Longer Life: Electrostatic coating ensures abrasive retention and durability.

-

-Customization: Available in various grit sizes for different stages of polishing.

-

-Compatibility: Suitable for ferrous and non-ferrous metals.

-

-Clean Operation: Minimal heat generation and dust.

-

-Environment Friendly: Reduces use of polishing compounds or fluids.

The camshaft lobes are more delicate than crank journals, so controlled polishing with uniform pressure is critical.

MORE’s electrostatic polishing flim with the sand tip facing outward, uses the high-voltage electrostatic field force to evenly distribute the fine abrasive on the high-strength base, which can be processed into a toothed belt to fit the processing surface and bright and delicate mirror effects.

The types include aluminum oxide, silicon carbide, diamond, etc to meet the processing requirements of workpieces of different hardness.

The crankshaft superfine micro polishing film use in a polishing machine, which can polish the main journal, connecting rod journal, fillet, shoulder and thrust surface at the same time. Its structure adopts a clamping type, and 4 pads (concave type) are used on each journal to press the film belt; the pads and film should be selected according to the material and hardness of the workpiece; then can ensure that each journal has a film to participate in the work; the polishing method is based on the principle of super finishing, and its efficiency and have a excellent work effective than oilstone.

—EDITOR: Doris Hu,Anna Wang

—POST: Doris Hu