Electrostatic film belt polishing camshaft,cranshaft

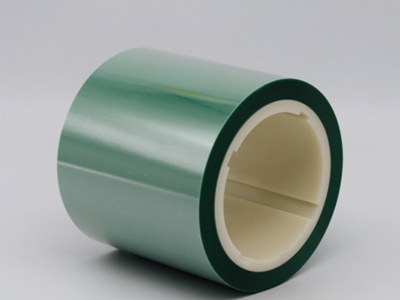

Microfinishing polishing belt

Eelectrostatic aluminum oxide film belt

Electrostatic silicon carbide film belt

Electrostatic diamond polishing film

What is electrostatic sand implantation?

Precision finishing film use high-voltage electrostatic field forces to implant fine abrasive grains on high-strength films, allowing the abrasive grains to be evenly distributed in a directional manner, providing higher grinding efficiency and bright and delicate polishing effects. Abrasive grains include aluminum oxide, silicon carbide, etc. Suitable for grinding and polishing materials of different hardness.

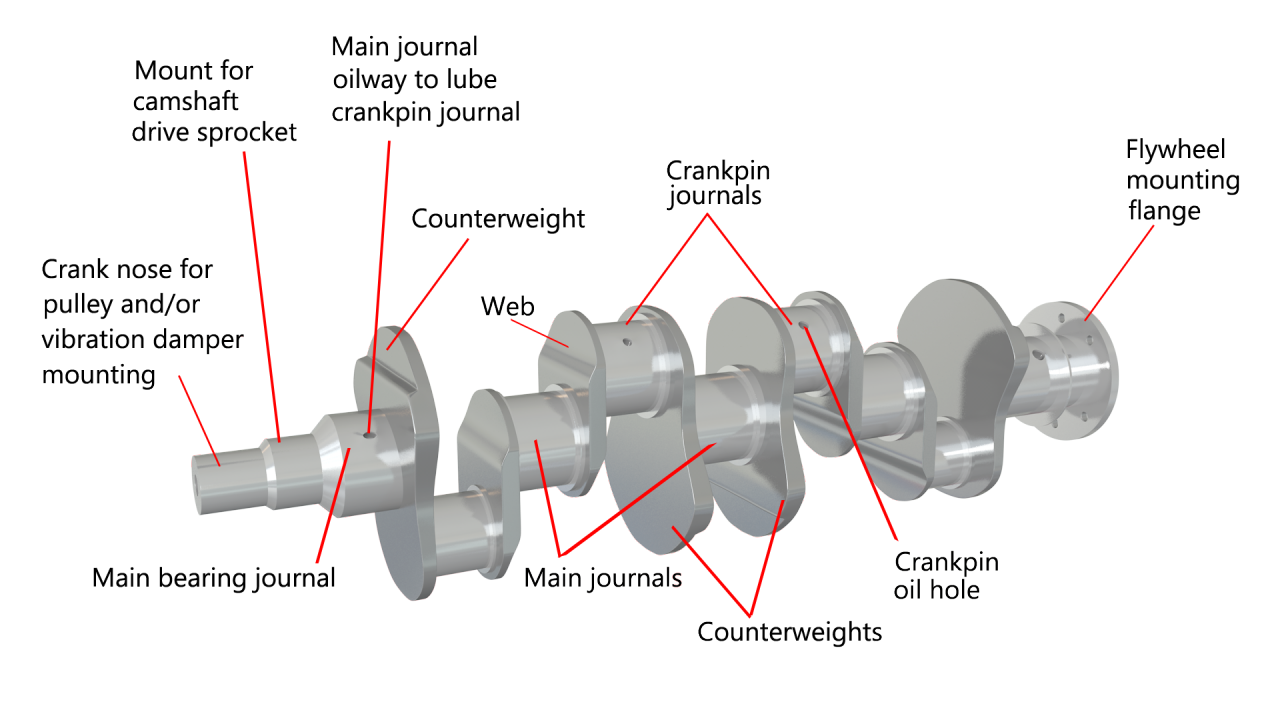

Why crankshaft/camshaft need to polishing?

The surface of the crankshaft has high requirements and generally needs to go through grinding and polishing processes. The profile and roughness of the crankshaft are its key indicators. The general profile is guaranteed by the rough grinding of the grinding wheel, while the precision grinding belt guarantees the surface roughness.

Purpose of polishing:

On the premise of ensuring the process accuracy and dimensional accuracy of parts, remove the unstable surface loose layer so that the parts can form a normal size of oil film thickness and good oil film rigidity during use, thereby ensuring the performance of the parts and increasing their service life.

The particle sizes generally used in automobile engines are 9μm, 15μm, 20μm, 30μm, and 40μm

MORESUPERHARD electrostatic polishing film abrasives include aluminum oxide, silicon carbide, diamond polishing film, etc.It is suitable for grinding and polishing materials with different hardness, like alloys, ceramics, metals, composite materials and other hard materials polishing.

Base of polishing film

Cloth base

It has a fiber structure, which affects the flatness of the grinding product: the abrasive particle size distribution is uneven, which is prone to deep scratches or insufficient grinding force; the cloth base will shrink and deform during wet grinding, which will affect the accuracy and consistency of polishing.

Film base

The abrasive is evenly distributed, with upward edges and corners, which is not easy to scratch and can maintain uniform and continuous cutting force and optimal surface accuracy; it has high tensile strength, water and heat resistance, and can be used for dry and wet grinding.

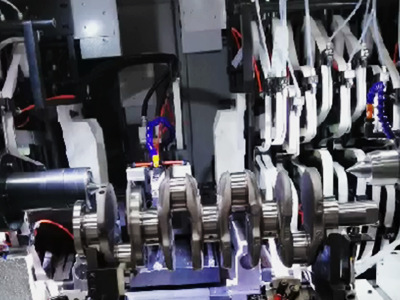

–Crankshaft polishing

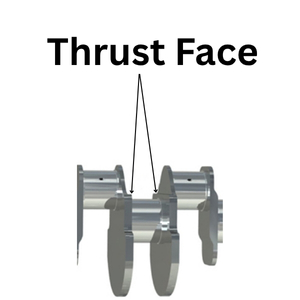

Polishing position: main shaft, connecting rod, shaft head (small head), flange, thrust surface.

As a kind of engine sliding bearing, the thrust plate mainly plays the role of axial support of the crankshaft in the engine. While ensuring the axial rotation of the crankshaft, it prevents the crankshaft from axial movement.

—Camshaft Polishing

Camshaft is a component in a piston engine. Its function is to control the opening and closing of the valve.

* Camshaft processing steps: lathe turning, milling machine, grinder, polishing film polishing

* Polishing medium: lubricating oil

*Polishing time: more than ten seconds to 1 minute (including forward and reverse rotation)

Polishing film specification for polishing camshaft

Commonly used aluminum oxide polishing film is 20μm, 15μm.

* For high requirements, add another process with 9 μm ;

* For low requirements, use cloth-based 600# (journal) and 800# (cam) polishing. A few use silicon carbide grinding belt.

Type and application of electrostatic film belt

| Type | Application |

| Electrostatic aluminum Oxide Polishing Film | * Metal and rubber cylinders.

* Camshaft and crankshafts. * Metallurgy. * Mirror roller * Gravure Roller * Several finishing processes. |

| Electrostatic silicon Carbide Polishing Film | |

| Electrostatic diamond polishing film | * Automobile parts(Crankshafts, camshafts, balance shafts, fuel injection parts, automatic transmission parts, transfer/mechanical LSD, etc.)

* Carbides and ceramics. * Sintered metals, super alloys and cast materials. * Glass, stone and gemstones. * Composite materials. * Various types of roll polishing * Automobile coating polishing * Flat displays and magnetic heads * Plastic lenses * Optical fiber ends and creation of analytical samples |

Speciation of electrostatic aluminum oxide film belt

| Micron Grade | Color |

| 0.05 | White |

| 0.3 | White |

| 0.5 | White |

| 1 | Green |

| 2 | Teal |

| 3 | Pink |

| 5 | Brown |

| 9 | Blue |

| 12 | Yellow |

| 30 | Blue |

| 40 | Blue |

| 60 | White |

Speciation of electrostatic silicon carbide film belt

| Micron Grade | Color |

| 3 | Gray |

| 5 | Gray |

| 9 | Gray |

| 15 | Gray |

| 30 | Green |

Speciation of electrostatic diamond film belt:

| Micron Grade | Color |

| 0.5 | White |

| 1 | Lavender |

| 3 | Pink |

| 6 | Brown |

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.