Case of Single Pass Diamond Honing Reamer for Honing Hydraulic Cylinder

What is hydraulic cylinders?

Hydraulic cylinders are one of the most critical components in hydraulic systems, widely used in construction machinery, automotive systems, aerospace, shipbuilding, and industrial equipment. They provide linear force and motion, converting hydraulic energy into mechanical energy. To ensure the smooth operation and long service life of hydraulic cylinders, the inner bore surface quality is of utmost importance.

Among the various processes used for bore finishing, honing stands out as a precise, cost-effective, and highly reliable method. Traditionally, multi-pass honing with vitrified abrasives or CBN stones has been used. However, in recent years, single pass diamond honing reamers have been increasingly adopted for hydraulic cylinder bore finishing due to their high efficiency, dimensional accuracy, and long tool life.

What is Honing?

Honing is a precision machining process used to improve the geometric form and surface finish of bores. It involves a tool called a hone, which carries abrasive stones or superabrasive (diamond/CBN) segments that contact the bore surface under controlled pressure while the tool rotates and reciprocates.

The main purposes of honing hydraulic cylinder bores are:

* Correct bore geometry (roundness, straightness, cylindricity).

* Improve surface finish (Ra ≤ 0.2 μm in many cases).

* Create cross-hatch patterns for better oil retention and lubrication.

* Remove hard surface layers caused by previous machining (e.g., boring, drilling).

Why Hydraulic Cylinders Need Single Pass Honing

Hydraulic cylinders have demanding requirements:

* High precision: bore tolerances are often within ±0.002 mm.

* Excellent surface finish: smooth bores minimize seal wear and leakage.

* Efficient production: manufacturers need to produce thousands of cylinders with consistent quality.

Conventional honing can meet these requirements but involves:

* Multiple strokes (time-consuming).

* Frequent tool adjustments.

* Higher costs in mass production.

Single pass diamond honing reamers overcome these issues by providing:

* Faster cycle times (up to 10× faster).

* Extended tool life (thanks to diamond abrasives).

* Consistency in bore size and finish.

What is a Single Pass Diamond Honing Reamer?

Unlike conventional honing, where the tool strokes back and forth many times, a single pass diamond honing reamer is designed to finish the bore in just one stroke.

Structure:

* A reamer-like body fitted with diamond or CBN abrasive sticks.

* Guide pads to stabilize the tool and control bore geometry.

* A progressive design where material is gradually removed along the tool length.

Working Principle:

* The tool is fed through the bore once (single pass).

* Diamonds cut and size the bore while guide pads maintain precision.

* Bore finish and geometry are achieved in a single operation, eliminating multiple honing strokes.

Key Features:

-

-

Uses fixed superabrasive (diamond/CBN) instead of loose abrasive grains.

-

Bore sizing and finishing happen simultaneously.

-

Ensures high repeatability and productivity.

-

How to Select the Right Single Pass Diamond Honing Reamer

When choosing a reamer for hydraulic cylinder honing, consider:

1. Workpiece Material:

-Steel (ST52, 42CrMo) → Diamond abrasive.

-Cast iron → CBN abrasive.

2. Bore Size:

Reamers are designed for specific bore ranges, usually 20–500 mm.

3. Surface Finish Requirements:

Select diamond grit size according to Ra target (e.g., D64–D91 for Ra ≤ 0.2 μm).

4. Production Volume:

-High-volume production benefits most from single pass reamers.

5. Coolant & Filtration:

-Clean honing oil with <10 μm filtration is critical for tool life.

Recently, Moresuperhard received an inquiry about honing a hydraulic cylinder, let’s see it together:

| Workpiece | Hydraulic cylinder |

| Workpiece material | 20MnCr5 |

| Workpiece hardness | 58-62 HRC |

| Size accuracy | ±0.005 |

| Processing allowance | 40μm |

| Surface finish requirement | Ra0.2 |

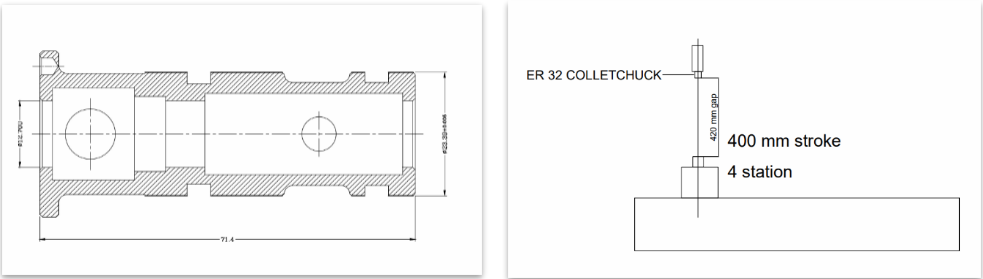

Our engineer analyzed the drawings and determined that this is a case of sequential holes that require honing at three different locations, with a travel of 420, four stations, and considering the machining allowance and surface finish requirements, they drew up the drawings and provided four grit recommendations: 100#, 150#, 200#, and 280#. We predict that each honing reamer tool can process approximately 10,000 workpieces.

—EDITOR: Doris Hu, Erin Zhang

—POST: Doris Hu