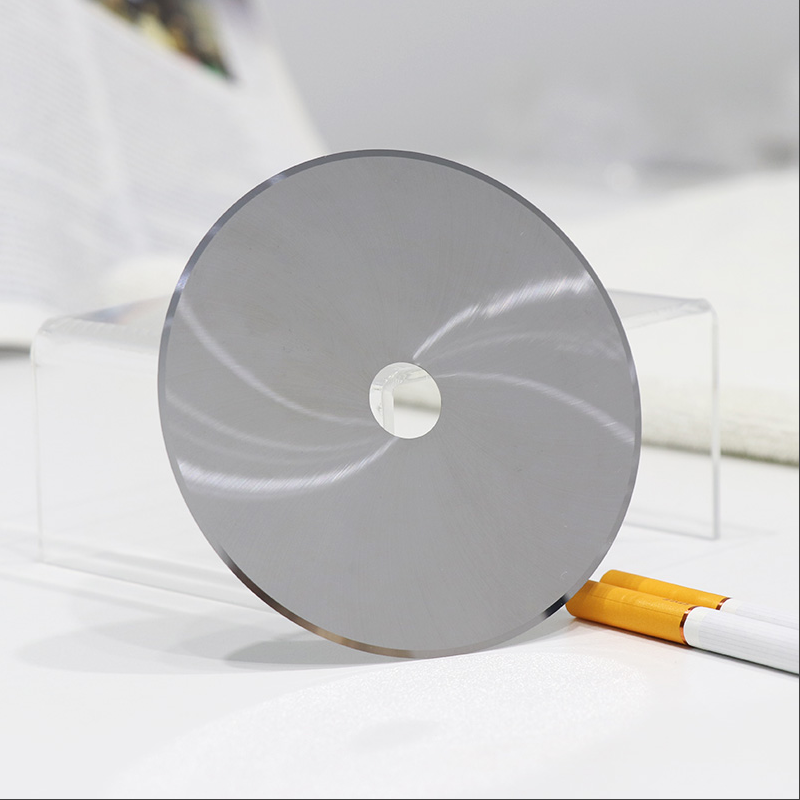

Hard alloy tobacco blades are essential tools used in the tobacco industry for cutting and processing tobacco leaves with precision. These blades, made of high-performance materials like tungsten carbide, are prized for their exceptional hardness, wear resistance, and durability. However, their brittleness and the demands of high-speed cutting in the tobacco processing environment mean they require regular sharpening to maintain their performance.

Sharpening hard alloy tobacco blades effectively requires the use of specialized grinding wheels. The resin diamond grinding wheel is one of the most suitable tools for this task, offering an ideal balance of precision, durability, and performance. In this article, we’ll explore the nature of hard alloy tobacco blades, the applications of these blades, the best practices for grinding them, and the advantages of using a resin diamond grinding wheel for sharpening.

What Are Hard Alloy Tobacco Blades?

Hard alloy tobacco blades are cutting tools typically made from tungsten carbide or other hard alloys. These materials offer excellent properties that are crucial for the high-performance requirements in tobacco processing machinery. The hardness and wear resistance of these blades allow them to maintain their cutting edges even under extreme conditions, making them ideal for slicing through tobacco leaves.

Composition and Properties of Hard Alloy Tobacco Blades:

* Tungsten Carbide: A material known for its exceptional hardness (around 80-90 HRC on the Rockwell scale) and wear resistance. Tungsten carbide is highly resistant to abrasion, which is why it’s commonly used for high-performance cutting tools.

* Cobalt Binder: Tungsten carbide particles are usually held together with a cobalt binder, which adds toughness and impact resistance to the blade.

* Precision Cutting Edge: The blade’s edge is carefully shaped for high precision, ensuring uniform cuts and preventing damage to the tobacco leaves.

Key Characteristics:

* Hardness: The blades can withstand prolonged use without losing their sharpness.

* Brittleness: While extremely hard, these blades can be brittle and prone to chipping or breaking, especially during the grinding process if the correct methods aren’t followed.

* Wear Resistance: Hard alloy tobacco blades can handle harsh materials and high-pressure cutting conditions without significant degradation.

Applications of Hard Alloy Tobacco Blades

Hard alloy tobacco blades are indispensable in the tobacco manufacturing industry. Their precision and durability ensure the efficient cutting of tobacco leaves, which is essential for product quality and production speed.

Common Applications of Hard Alloy Tobacco Blades:

* Tobacco Leaf Cutting: These blades are primarily used in tobacco leaf cutting machines, where they slice through tobacco leaves into strips or smaller pieces for further processing.

* Shredding and Chopping: Hard alloy tobacco blades are also utilized in shredders and choppers to break down large tobacco leaves into small, uniform pieces.

* Precision Cutting: For applications where uniformity in size and shape is critical, these blades are used in precision cutting machines to ensure accurate dimensions for each tobacco leaf or tobacco product.

* Tobacco Packaging: These blades are also used in cutting packaging materials for tobacco, ensuring smooth and precise cuts to fit packaging specifications.

Given the critical nature of these blades in tobacco processing, keeping them sharp is vital for maintaining operational efficiency and product quality.

How to Grind Hard Alloy Tobacco Blades?

Grinding hard alloy tobacco blades requires a careful approach, given the material’s hardness and brittleness. If not done properly, the grinding process can lead to chipping, cracking, or overheating the blade. Below is a step-by-step guide on how to grind these blades effectively.

1. Inspecting the Blade

* Before starting the grinding process, it’s important to inspect the blade for damage, wear, or any chips in the edge. The condition of the blade will determine the grinding approach.

* If the blade is excessively worn or damaged, it may require rough grinding to remove the damaged portions before sharpening the edge.

2. Setting the Correct Bevel Angle

* Hard alloy tobacco blades typically have a 6° bevel angle. Ensuring that the bevel angle is maintained during the grinding process is crucial for ensuring the blade retains its cutting edge.

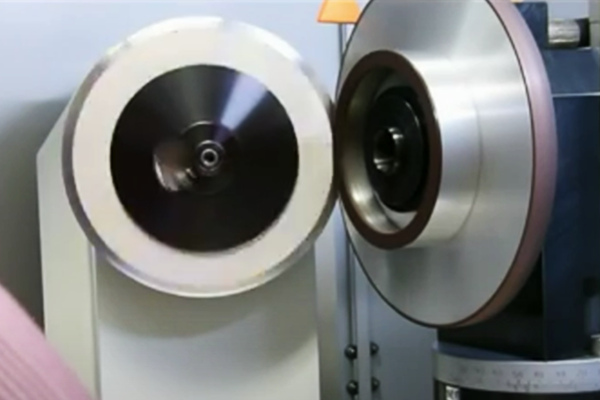

3. Selecting the Correct Grinding Wheel

* Resin diamond grinding wheels are ideal for sharpening hard alloy tobacco blades because they provide an optimal balance of cutting efficiency, long tool life, and fine surface finish.

* Grit Size: Start with a coarse grit (e.g., 200-400 grit) for rough grinding, followed by a fine grit (e.g., 800-1000 grit) for the finishing process.

* Wheel Type: Resin-bonded diamond wheels are excellent for this purpose, providing the necessary hardness to sharpen the tough tungsten carbide material without causing damage.

4. Grinding Process

* Rough Grinding: Use a coarse diamond wheel to remove bulk material from the blade. Perform this step with caution, as the blade’s brittle nature means too much force could lead to breakage.

* Fine Grinding: Switch to a finer grit wheel for fine sharpening to achieve the desired sharpness and a smooth cutting edge.

* Polishing: After grinding, use a polishing wheel to remove any remaining roughness or burrs from the blade’s edge.

5. Cooling and Lubrication

* Cooling: The grinding process can generate substantial heat, which can damage the blade or the grinding wheel. Use coolants or lubricants to prevent overheating.

* Lubrication: Proper lubrication reduces friction and ensures the grinding wheel operates efficiently.

6. Final Inspection

* After grinding, inspect the blade for any defects. Use a microscope or magnifying glass to check for smoothness and sharpness.

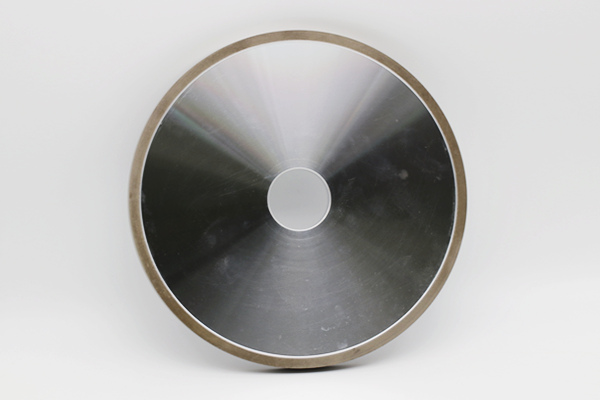

Advantages of Resin Diamond Grinding Wheel for Grinding Hard Alloy Tobacco Blades

The resin diamond grinding wheel offers several advantages when it comes to sharpening hard alloy tobacco blades:

1. Superior Cutting Efficiency

Resin diamond grinding wheels are incredibly effective at grinding tungsten carbide and other hard alloys. Diamond’s hardness allows it to grind through these tough materials efficiently without excessive force.

2. Long Tool Life

The resin bond in diamond wheels provides a long lifespan for the wheel. Unlike conventional grinding wheels, resin diamond wheels maintain their effectiveness over extended periods, reducing the need for frequent replacements.

3. High Precision

Resin diamond grinding wheels maintain excellent form retention, allowing for consistent results with each sharpening session. This is important when sharpening hard alloy tobacco blades that require precision to maintain their cutting performance.

4. Cool Grinding

The vitrified bond in the resin wheel helps dissipate heat efficiently, minimizing the risk of thermal damage to the blade. This ensures that the blade retains its hardness and does not lose its edge due to overheating.

5. Smooth Finish

These grinding wheels provide a fine finish with minimal burr formation, ensuring that the blade is not only sharp but also smooth, preventing issues with the cutting process.

Customer Problems and Solutions

Problem 1: Blade Prone to Chipping or Breaking with a 15mm Thick Grinding Wheel

Solution: Use a thinner grinding wheel (approximately 6mm thick) for better control and less pressure on the blade. This will reduce the risk of chipping or cracking.

Problem 2: Fine-Grained Grinding Takes Too Long and Has Low Efficiency

Solution: Start with a coarser grit (e.g., 200# grit) to remove material quickly, then switch to a finer grit (e.g., 800# grit) for the final sharpening. This process improves efficiency and reduces the overall grinding time.

Problem 3: Feed Rate of 0.005 Will Break the Blade

Solution: Use a slower feed rate for fine grinding (e.g., 0.001 feed rate) to ensure a more controlled and smoother grinding process. Gradually increase the feed rate to improve efficiency.

Problem 4: Maximum Speed of Equipment is 4500 RPM

Solution: For equipment with a maximum speed of 4500 RPM, the recommended speeds for grinding are 2000-2500 RPM. This ensures safe and effective grinding without causing overheating.

Moresuperhard Suggestions for Effective Grinding:

* Resin Diamond Grinding Wheel 200×31.75 for Rough Grinding:

Use this for rough grinding to remove bulk material quickly and efficiently, reducing the risk of damage.

* Resin Diamond Grinding Wheel 250×31.75 for Finishing:

Use this for fine grinding and finishing the edge for a sharp, smooth surface.

| Workpiece | Hard alloy tobacco blades 100x15x0,3mm | |

| Grinding Wheel |

Resin diamond grinding wheel |

1A1- 200×31,75 D46 for rough grinding |

| 1A1- 250×31,75 2000# for finishing | ||

| Grinding Machine | EYAN 500D 3A | |