Case of PU polishing pad for polishing optical lens

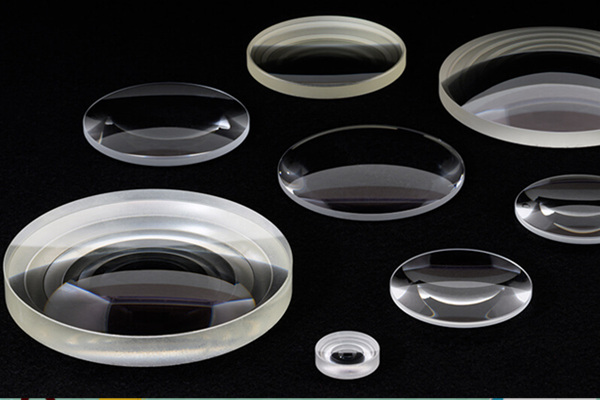

What is optical lens?

Optical lenses/lenses are usually made of optical glass or other special materials, generally referring to lenses that can transmit and adjust visible light.

As we all know, optical lenses must be measured by optical instruments to check whether the purity, transparency, uniformity, refractive index and dispersion rate meet the specifications. Qualified glass blocks are heated and forged to form optical lens blanks.

Optical glass substrates are usually processed by cutting, rounding, rough grinding, fine grinding, polishing, edge grinding, coating, gluing, ink coating, etc.

Why do optical lenses need to be polished?

In the manufacturing process of optical lenses, the polishing process is a key link that determines the surface quality of the lenses. Polishing pads of different materials, due to their unique physical properties and chemical compositions, are suitable for various precision polishing scenarios.After the optical lens is finely ground with abrasive fluid, there is still a thick crack layer on the surface. The method to eliminate this crack layer is polishing.

In the processes of edge grinding/grinding/polishing, grinding fluid and polishing powder are needed to assist the operation.

After the optical lens is finely ground with abrasive fluid, there is still a crack layer about 2-3m thick on its surface. The method to eliminate this crack layer is polishing. The mechanism of polishing is the same as that of grinding, but the tool materials and polishing slurry used are different. The materials used for polishing include cloth, polishing pad (polyurethane), etc.

What is Polyurethane polishing pad?

Product process and use

Polyurethane is used as the main body, and a highly elastic and wear-resistant polishing material is made through multiple processes. Suitable for surface polishing of precision parts such as metal/optics/glass/ceramics/semiconductor chips

* PU Polishing pads containing cerium oxide – mainly for improving polishing efficiency;

* PU Polishing pads containing zirconium oxide – mainly for improving finish;

* PU Polishing pads without fillers – mainly for stabilizing the aperture during polishing.

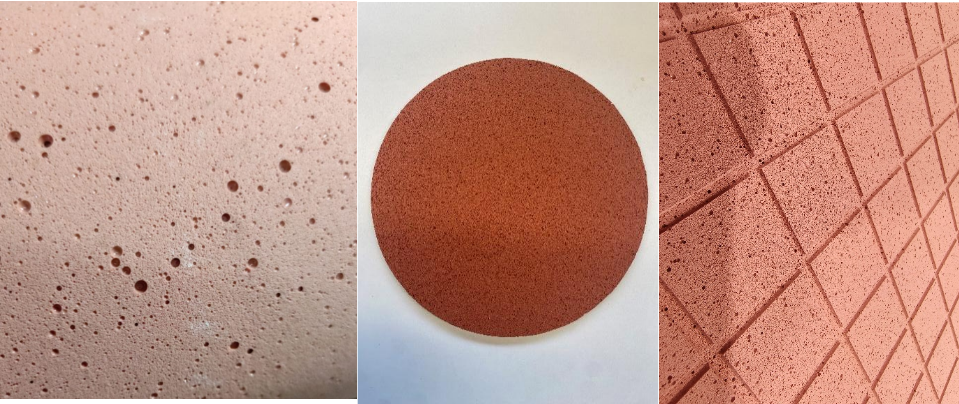

Different functions of polyurethane polishing pad foaming holes

Polishing pads with more foaming holes are conducive to the fluidity of polishing powder and the polishing rate is better.

Polishing pads with fewer foaming holes have stronger hydrophilic properties.

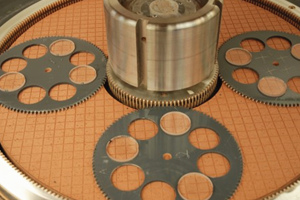

Advantages of polyurethane polishing pad punching

In order to increase the fluidity of the polishing liquid and improve the polishing efficiency, a punched polyurethane polishing leather is used.

Generally, the size of the hole is about 2mm. According to the aperture size of the lens, the rotation speed of the equipment, and the R value, the arrangement of the holes is divided into 90 degrees, 60 degrees, and 45 degrees, which are more suitable for spherical processing.

Advantages of polyurethane polishing pad slotting

Polishing pad slotting is to increase the fluidity of the polishing liquid and improve the polishing rate.

You can choose a slotted polyurethane polishing pad, generally with a thickness of 1.5mm or more, and the slotted models are 20mm and 30mm respectively.

The slotted polishing pad will reduce the scratches on the lens caused by larger particles in the polishing powder, and is mainly used for plane processing.

Application of polyurethane polishing pad:

Polyurethane polishing pad is applied to the thinning and polishing of the surfaces of precision materials such as precision optical glass, sapphire, filters, ceramic substrates, quartz glass, disk substrates, laser crystals, silicon wafers, precision metals, watch glass and III-V compound semiconductor materials.

Polyurethane polishing pads are widely used in the following fields:

* In the conductor industry, polyurethane polishing pads are used in the semiconductor manufacturing process to polish the surface of silicon wafers and improve product quality.

* In the optical industry, polyurethane polishing pads play a significant role in the processing of optical components, such as spectacle lenses and lenses.

* In the automotive industry, polyurethane polishing pads are used for polishing automotive parts, such as engine blocks and crankshafts.

* In the jewelry industry, polyurethane polishing pads can be used for surface polishing of jewelry to enhance the product’s luster.

Recently, we have received a request from an Indian customer for polyurethane polishing pads for the polishing of optical lenses.

| Abrasive filler | cerium oxide 3mm cerium based 3mm |

| Size | 1397*584*3.0 |

| Shape | Square |

| Workpiece for polishing | Optical lens |

With the continuous improvement of the precision requirements for optical manufacturing, polishing technology continues to develop in the direction of specialization and refinement. Correct selection and standardized use of polishing materials can significantly improve product yield and processing efficiency.

—EDITOR: Doris Hu,Erin Zhang

—POST: Doris Hu