Case of metal diamond optical profile grinding wheel for grinding carbide mould

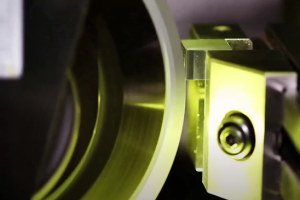

In the field of high-precision carbide mold machining, optical profile grinding is a core process that determines the accuracy, contour consistency, and service life of the mold cavity. Whether it’s the complex curved surfaces of injection molds, the sharp edges of stamping dies, or the precision cavities of ceramic pressing molds, the grinding tools require exceptional contour replication capabilities, dimensional stability, and wear resistance.

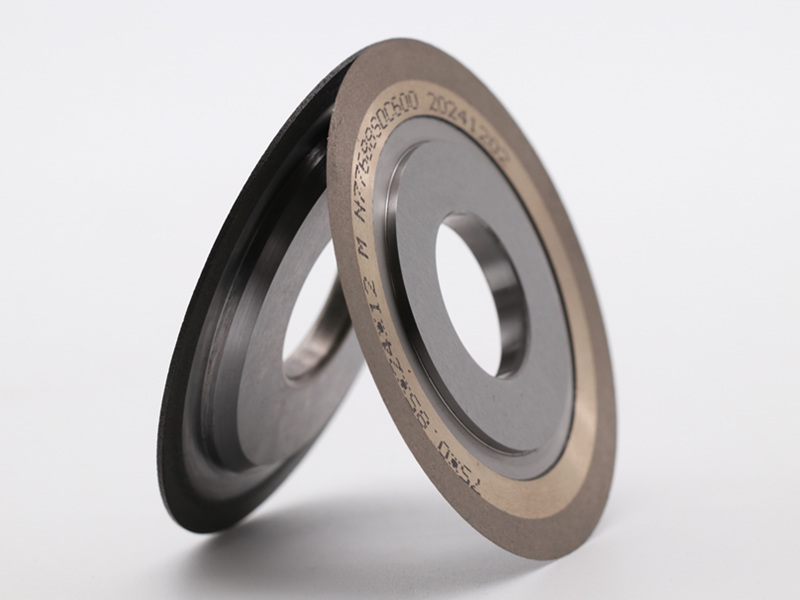

Metal-bonded optical profile diamond grinding wheels, with their superior forming accuracy, high rigidity, and long lifespan, have become the preferred tool for carbide mold machining.

However, carbide mold components made of different materials such as gray cast iron, stainless steel, and ceramics have significantly different material properties, requiring distinctly different grinding strategies and grinding wheel selections. Choosing the right grinding wheel can lead to “doubled accuracy, improved efficiency, and optimized costs”; conversely, improper selection can result in mold contour distortion, surface defects, and premature grinding wheel wear.

Why Optical Profile Diamond Grinding Wheels are Core Equipment for Precision Mold Machining

The core difference between optical profile diamond grinding wheels and traditional grinding tools lies in their ability to accurately replicate complex mold profiles and maintain dimensional stability over time. This is the key reason why they have become the “standard” for precision hard alloy mold machining.

(I) The Decisive Role of Optical Profile Grinding in Mold Accuracy

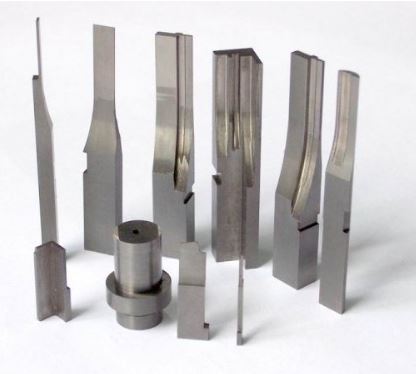

The core value of hard alloy molds lies in “profile accuracy”—the cavity profile of injection molds directly determines the dimensional accuracy of plastic parts, the cutting edge profile of stamping molds affects the quality of sheet metal stamping, and the cavity profile of ceramic pressing molds is related to the consistency of ceramic part forming. Optical profile grinding, through the precise contact movement between the grinding wheel and the mold, accurately replicates the grinding wheel profile onto the mold surface. Its profile accuracy can be controlled within ±0.001mm, and the surface roughness is as low as Ra0.02μm, meeting the processing requirements of ultra-high precision molds.

(II) The Core Differences Between Optical Profile Grinding Wheels and Ordinary Grinding Wheels

Compared with ordinary diamond grinding wheels, optical profile diamond grinding wheels have three core advantages:

1. Stronger Profile Forming Capability:

Using CNC precision forming technology to process the grinding wheel profile, it can achieve precise preparation of complex curved surfaces and irregular profiles, while ordinary grinding wheels cannot guarantee the accuracy of complex profiles;

2. Superior Dimensional Stability:

The rigidity of the metal binder is far higher than that of resin and ceramic binders. The deformation of the grinding wheel during grinding is extremely small, allowing it to maintain profile accuracy for a long time and avoid frequent dressing;

3. Wider Adaptability:

It can be precisely adapted to different mold materials by adjusting the diamond grit size and binder hardness, while ordinary grinding wheels are mostly general-purpose and cannot meet the processing needs of multiple materials.

(III) The Core Advantages of Metal Bonded Abrasives

Metal-bonded abrasives (primarily copper-based and iron-based bonds) are the core technological highlight of optical profile diamond grinding wheels, and their advantages are particularly prominent in the machining of cemented carbide molds:

– High Bonding Strength:

Forms a strong metallurgical bond with the diamond abrasive grains, providing strong holding power and enabling it to withstand the high loads of cemented carbide grinding, preventing abrasive grain shedding;

– Excellent Shape Retention:

The metal bond has high hardness and good wear resistance, resulting in slow wear of the grinding wheel profile, reducing the number of dressing operations and improving processing efficiency;

– Good Thermal Conductivity:

The thermal conductivity of metal bonds is 5-8 times that of resin bonds, allowing for rapid dissipation of grinding heat and preventing mold deformation or burning due to high temperatures.

(IV) Typical Mold Industry Applications

Metal-bonded optical profile diamond grinding wheels have been widely used in four core mold fields, playing a crucial role in processing different materials:

– Injection Molds: Profile grinding of gray cast iron mold bases, precision machining of stainless steel inserts;

– Stamping Dies: Profile forming of cemented carbide cutting edges, precise grinding of stainless steel shims;

– Ceramic Pressing Molds: Precision grinding of ceramic cavities, adaptive machining of gray cast iron bases;

– Die Casting Molds: Profile machining of stainless steel cores, wear repair of gray cast iron mold bodies.

Selection of Diamond Grit Size and Binder Hardness for Different Materials

Diamond grit size (abrasive particle size) and binder hardness are key parameters that determine the cutting efficiency, profile accuracy, and service life of a grinding wheel. They must be precisely matched to the material characteristics and processing requirements (rough grinding/fine grinding).

(I) Gray Cast Iron: Coarse grit for rough grinding, medium grit for fine grinding, balancing efficiency and lifespan

The processing of gray cast iron mold parts mainly focuses on “rapid material removal and ensuring contour formation.” The grit size selection should prioritize both efficiency and wear resistance:

– Rough grinding stage (e.g., grinding of gray cast iron mold base blanks):

It is recommended to choose 80#-120# coarse-grit diamonds. The large spacing between cutting edges and wide chip evacuation channels allow for rapid removal of a large amount of grinding debris, preventing clogging; a medium-hard metal binder (hardness HRB85-90) should be selected to improve the wear resistance of the grinding wheel and cope with the abrasive wear of gray cast iron;

– Fine grinding stage (e.g., fine finishing of gray cast iron mold base contours):

It is recommended to choose 150#-200# medium-grit diamonds. While ensuring a certain level of efficiency, this reduces surface scratches and improves contour accuracy; the binder hardness can be slightly adjusted to HRB90-95 to balance wear resistance and shape retention.

(II) Stainless Steel: Primarily medium to fine grit, optimized for sharpness, with controlled binder hardness

Grinding of stainless steel requires avoiding excessive processing hardening caused by overly coarse abrasive grains. The selection of grit size and binder hardness is centered on “sharpness and heat dissipation”:

– Rough grinding stage (e.g., removing excess material from stainless steel inserts):

It is recommended to choose 120#-180# medium-grit diamond abrasives to avoid excessive grinding force caused by overly coarse abrasive grains; a medium-soft metal binder (HRB80-85) should be selected to improve the self-sharpening ability of the grinding wheel and prevent abrasive grain passivation;

– Fine grinding stage (e.g., precision grinding of stainless steel core contours):

It is recommended to choose 200#-320# fine-grit diamond abrasives to achieve precise contour replication through dense, fine cutting edges and reduce burr generation; the binder hardness should be adjusted to HRB85-90, balancing shape retention and surface quality.

– Key reminder: Using grinding wheels with grit sizes below 60# for stainless steel grinding is strictly prohibited, as this will exacerbate work hardening and material adhesion, leading to grinding wheel clogging and workpiece burning.

(III) Ceramics: Fine/Ultra-fine grain size, low-hardness binder, low-stress grinding

The brittleness of ceramics necessitates the use of a “fine grain size + low-hardness binder” combination to achieve low-stress grinding through small cutting forces:

– Fine grinding stage (e.g., ceramic cavity contour machining):

It is recommended to choose 320#-400# fine-grained diamond abrasives. The small cutting force of individual abrasive grains effectively reduces stress concentration and prevents cracking; a soft metal binder (HRB75-80) is selected to improve the self-sharpening ability of the grinding wheel and prevent the sudden increase in grinding force caused by abrasive grain passivation;

– Polishing stage (e.g., ceramic bushing surface machining):

It is recommended to choose 600#-1000# ultra-fine-grained diamond abrasives to achieve mirror-level surface quality (Ra0.02-Ra0.1μm); the binder hardness can be reduced to HRB70-75 to ensure the polishing effect.

Grinding Wheel Structure Design and Contour Accuracy Control Key Points

The structural design of optical profile diamond grinding wheels (such as contour shape, chip removal grooves, and base parameters) directly affects contour replication accuracy, chip removal effect, and grinding stability, and is crucial for ensuring the quality of hard alloy mold processing.

(I) Contour Edge Radius Control and Sharpness Requirements

The contour edge accuracy of hard alloy molds (such as the cutting edge of stamping dies and the corners of injection mold cavities) directly determines the performance of the mold:

– Cutting edge molds (e.g., stainless steel stamping edges): The grinding wheel edge radius needs to be controlled within 0.005mm to ensure the sharpness of the cutting edge and prevent burrs during stamping;

– Cavity molds (e.g., ceramic pressing cavities): The grinding wheel edge needs to be micro-chamfered (radius 0.01-0.02mm) to prevent chipping at the corners of the mold cavity;

– Key measure: Choose grinding wheels with CNC precision forming technology, where the contour edge processing accuracy can be controlled within ±0.001mm, meeting the needs of high-precision molds.

(II) Chip Removal Groove and Chip Space Design: Adapting to Different Material Chip Removal Needs

Poor chip removal can lead to chip clogging and grinding wheel loading, which in turn affects contour accuracy and workpiece quality. The chip removal structure needs to be designed according to the chip characteristics of the material:

– Gray cast iron grinding: The chips are large and hard. A “sparse tooth layout + wide chip removal groove” design is used, with a chip removal groove width ≥2mm and spacing ≥5mm, to quickly remove chips and avoid secondary wear;

– Stainless steel grinding: The chips are long and thin and easily adhere. A “spiral chip removal groove + narrow spacing” design is used, with a chip removal groove width of 1-1.5mm and a spiral angle of 30°-45°, to timely remove adhering chips and prevent clogging;

– Ceramic grinding: The chips are fine powder. A “shallow groove + dense layout” design is used, with a chip removal groove depth ≤1mm, to ensure grinding stability and prevent powder accumulation.

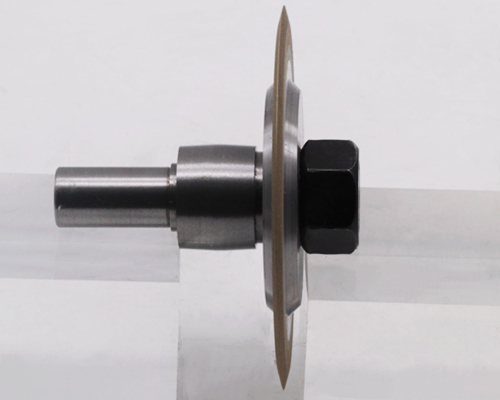

(III) Grinding Wheel Base Parameters: Ensuring Rigidity and Stability

The diameter, thickness, and runout tolerance of the grinding wheel base (metal base) directly affect grinding stability and profile accuracy:

– Diameter and Thickness:

Selected according to mold size; small molds (such as miniature injection molds) are suitable for Φ100-150mm grinding wheels with a thickness of 5-10mm;

Large molds (such as stamping molds) are suitable for Φ200-300mm grinding wheels with a thickness of 10-15mm;

– Runout Tolerance:

The end face runout of optical profile grinding wheels should be ≤0.002mm, and the radial runout ≤0.001mm, to avoid profile deviation during grinding;

– Base Material:

Preferably choose 45# steel or aluminum alloy base. 45# steel base has high rigidity and is suitable for heavy-duty grinding (such as rough grinding of gray cast iron); aluminum alloy base is lightweight and suitable for high-speed grinding (such as precision grinding of stainless steel).

(IV) Thermal Stability Control of Metal Bonded Base

Grinding of cemented carbide molds is sensitive to temperature, so the thermal stability of the metal bonded base needs to be carefully ensured:

– Base Heat Treatment:

Using tempering treatment (hardness HRC28-32) reduces the thermal deformation coefficient of the base and prevents base deformation caused by high grinding temperatures;

– Heat Dissipation Structure:

Opening annular heat dissipation grooves on the side of the base increases the heat dissipation area and accelerates heat conduction, which is especially suitable for grinding materials that easily generate heat, such as stainless steel and ceramics.

Advantages of Metal-Bonded Diamond Grinding Wheels for Machining Carbide Molds

High contour forming accuracy, suitable for complex mold structures

The decisive role of optical contour grinding on mold accuracy

Carbide molds often contain complex structures such as irregularly shaped cavities, complex curved surfaces, and sharp edges, requiring extremely high contour replication accuracy (tolerance needs to be controlled within ±0.001mm). Metal-bonded diamond grinding wheels utilize CNC precision forming technology to accurately machine curved structures that match the mold contour. The grinding wheel contour accuracy error is ≤±0.001mm, enabling “one-time forming” of complex contours without multiple adjustments.

Compared to traditional grinding wheels, its curved contour design perfectly fits the mold surface, avoiding grinding interference, and is especially suitable for machining complex structures such as gray cast iron injection mold cavities, stainless steel stamping die edges, and ceramic pressing mold irregular grooves. The contour accuracy and dimensional consistency of the processed mold are significantly improved, effectively reducing subsequent polishing steps and improving processing efficiency.

The core value of carbide molds lies in “contour accuracy”—the cavity contour of injection molds directly determines the dimensional accuracy of plastic parts, the edge contour of stamping dies affects the quality of sheet metal stamping, and the cavity contour of ceramic pressing molds is related to the forming consistency of ceramic parts. Optical contour grinding, through the precise fitting movement of the grinding wheel and the mold, accurately replicates the grinding wheel contour onto the mold surface. Its contour accuracy can be controlled within ±0.001mm, and the surface roughness is as low as Ra0.02μm, meeting the processing requirements of ultra-high precision molds.

Metal bond is wear-resistant, resulting in a long grinding wheel lifespan

The core difference between optical contour grinding wheels and ordinary grinding wheels

Carbide molds have extremely high hardness (above HRC60). Traditional resin and ceramic bonded grinding wheels are prone to problems such as abrasive particle shedding and rapid grinding wheel wear, leading to increased processing costs. Metal-bonded diamond grinding wheels utilize copper-based and iron-based metal binders, forming a strong metallurgical bond with diamond abrasive particles through vacuum brazing technology. With a bonding strength of ≥50MPa, they firmly hold the abrasive particles, preventing particle detachment under high-load grinding conditions.

The metal binder itself possesses high hardness and excellent wear resistance, resulting in slow wear of the grinding wheel profile and a service life 3-5 times longer than traditional resin-bonded grinding wheels. Its wear resistance advantage is particularly prominent in addressing abrasive wear in gray cast iron and work hardening wear in stainless steel, reducing grinding wheel replacement frequency and downtime, and lowering the unit cost of mold processing.

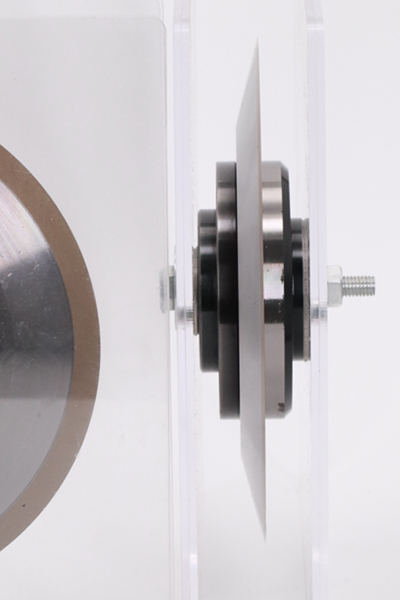

Recently, Moresuperhard receive one inquiry about optical profile carbide mould, lets see it together:

| Grinding Wheel bond | Metal bond |

| Wheel material | Diamond |

| Wheel size | D180*T8*X1*H31.75 with 400# grit |

| Workpiece | Carbide mould |

—EDITOR: Doris Hu

—POST: Doris Hu