Case of metal CBN cut off wheel for SUH11 valve CBN

What is the function of valve?

The function of the valve is specifically responsible for inputting air into the engine and exhausting the burned exhaust gases. From the engine structure, it is divided into intake valve and exhaust valve. The function of the intake valve is to suck air into the engine and mix it with fuel for combustion; the function of the exhaust valve is to discharge the burned exhaust gas and dissipate heat.

The valve is composed of a valve head and a stem. The temperature of the valve head is very high (intake valve 570~670K, exhaust valve 1050~1200K), and it also bears the pressure of the gas, the force of the valve spring and the inertial force of the transmission component. Its lubrication and cooling conditions are poor, requiring the valve to It has certain strength, stiffness, heat resistance and wear resistance. The intake valve is generally made of alloy steel (chromium steel, nickel-chromium steel), and the exhaust valve is made of heat-resistant alloy (silicon-chromium steel).

SUH11 is a martensitic heat-resistant steel containing chromium, silicon and carbon. It is mainly used as a material for gasoline and diesel engine intake valves or burner nozzles.

One of the key advantages of metal CBN cutting discs is their ability to deliver enhanced precision. SUH11 is a kind of heat-resistant stainless steel used in the manufacture of valves, which demands consistent and accurate machining. Metal CBN cutting discs provide a precise cutting edge that enables operators to achieve tight tolerances and maintain dimensional accuracy throughout the machining process. This level of precision is essential for ensuring the proper fit and functionality of valves.

Metal CBN cutting discs, on the other hand, are designed to withstand the demands of cutting SUH11 materials. Their superior hardness and thermal stability allow for high cutting speeds, reduced machining time, and extended tool life, resulting in improved overall productivity.

Longer Tool Lifespan

When cutting SUH11 valves, tool wear and premature replacement can be costly and time-consuming. Metal CBN cutting discs have a remarkable wear resistance due to their reinforced CBN cutting materials. This enables them to maintain their cutting edge for much longer periods without the need for frequent replacements or re-sharpening. The extended tool life reduces downtime and increases productivity, making metal CBN cutting discs a cost-effective solution for machining SUH11 material valves.

Reduced Heat Generation

SUH11 material generates substantial heat during the cutting process due to its heat-resistant properties. This heat can cause thermal damage to both the material and the cutting tool, potentially compromising the quality of the final product. Metal CBN cutting discs have excellent thermal stability and high thermal conductivity, allowing for efficient heat dissipation. By minimizing heat generation, these cutting discs help maintain the structural integrity of the material and promote a longer lifespan for both the tool and the valves being machined.

Conclusion:

Machining SUH11 material valves presents unique challenges due to their heat resistance and hardness. However, metal CBN cutting discs offer a precise and efficient solution to overcome these difficulties. With their enhanced precision, improved efficiency, extended tool lifespan, and reduced heat generation, metal CBN cutting discs provide a reliable and cost-effective option for cutting SUH11 valves. By utilizing this advanced cutting technology, industries can ensure the production of high-quality valves that meet the stringent requirements of various applications.

Recently Moresuperhard had a customer, who need cutting valve, we provide solutions for him as follows:

| Type of cutting disc | Metal CBN Cutting wheel |

|

Workpiece material |

1. cut material workpieces SUH11 |

| 2. cutting process is DRY ( no coolant used ) | |

| 3. machine use is automatic cutting machine | |

| 4. hardness of work piece is under 45 HRC | |

| Size | 205x1x90x0.8×5 |

| Spec | B60 |

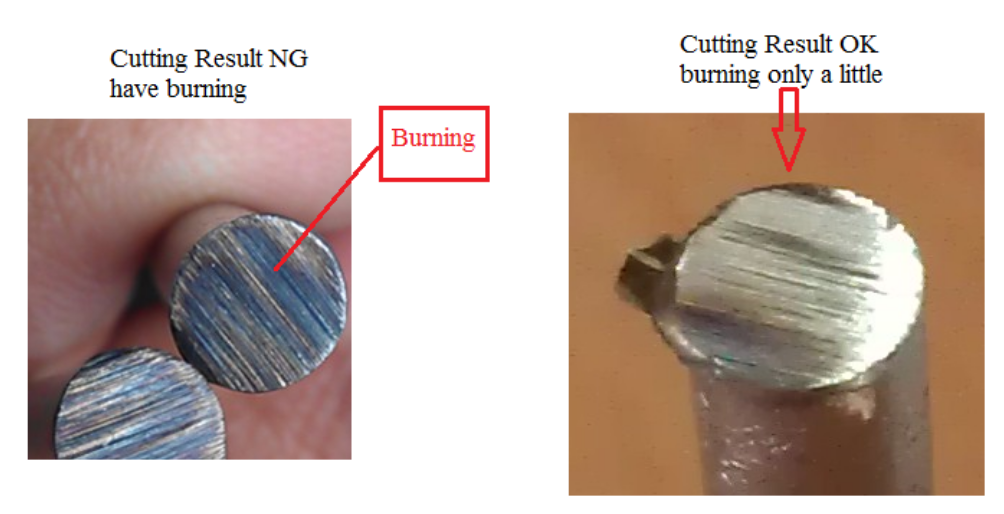

The customer has burn scratches by comparing the cutting pieces of other brand, and the picture on the right is our home with good results.

Customers compare the cutting wheel with other supplier, the others cutting result NG have burning and scratches, our cutting wheel result OK burning a litter, we will continue to improve until there are no burns…

—EDITOR: Doris Hu,Anna Wang

—POST: Doris Hu