What diamond tools are used to process glass lense?

What is lense?

Lenses are a type of product that we are very familiar with. The glasses and mobile phone lenses that everyone uses daily, and even the telescopes and microscopes used in outdoor and popular science scenes also use lenses equipped with various lens combinations. Optical lenses vary according to their shapes, and common ones include concave lenses, convex lenses, and prism mirrors.

The most command glass lens include two types which is glass material and resin material, and the resin material also can be divide intothermosetting resin material and thermoplastic resin material.In high-end manufacturing or testing equipment, high-precision lenses are required, which require fine polishing.

Moresuperhard can provide grinding wheels(milling grinding wheel and centering wheel) and polishing tools(diamond pellets and polishing pad) for lense processing.

How to manufature lense?

Process: lens blank – rough grinding (matting) – fine grinding and polishing – inspection and storage.

Processing introduction

(1) Glass Lens blank

In mass production, the use of type material blank processing to reduce the workload of grinding, the general blank convex mirror degree and processing mirror degree is similar, the blank concave mirror degree is less than the processing mirror degree.

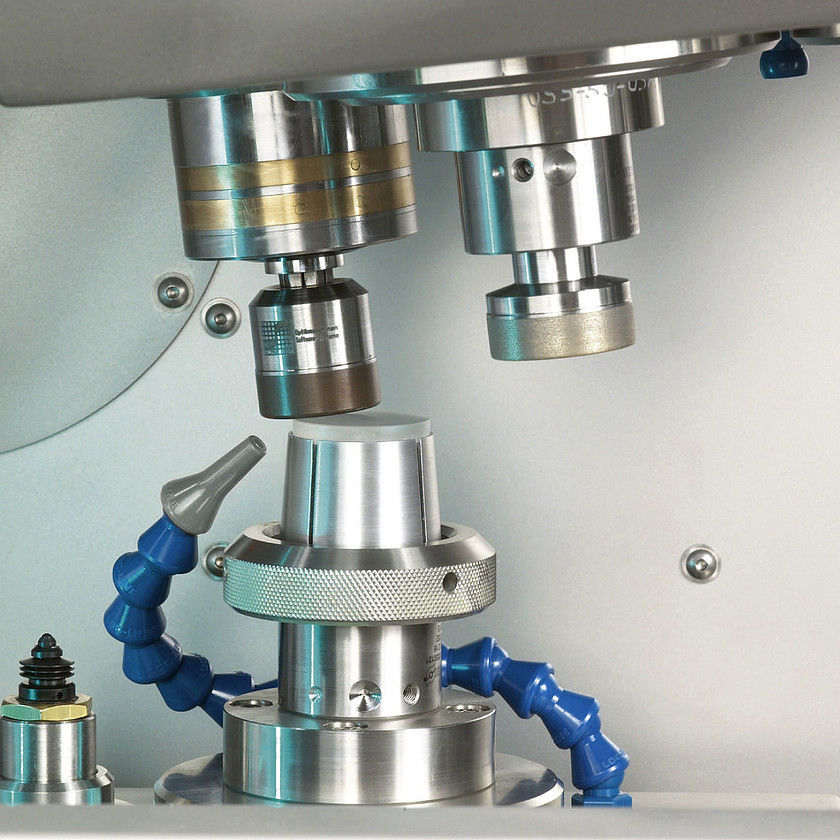

Rough grinding (milling grinding wheel for lense)

Using milling machine for rough single grinding the glass lens, that achieve a certain radius of curvature and surface roughness.

Grinding principle: The Angle between the axis of the diamond grinding wheel and the axis of the working axis of the lens is a, intersecting at. The points, each rotating around the axis, combine the two movements to grind out the radius of curvature of the sphere required for the lens. The spherical diopter changes as long as the included Angle is adjusted to a.

Fine grinding wheel and polishing tools for polishing lense

Using different abrasive material but the same machine for fine grinding and polishing, diamond pellets for fine grinding and Polyurethane, oxidized lung pads for polishing. Finishing is to improve the curvature radius and surface roughness of the lens surface after rough grinding (matting).

Chemical mechanical polishing is a polishing method that relies on cutting and plastic deformation of the material surface to remove the polished convex parts to obtain a smooth surface. Mechanical polishing is also called polishing powder polishing. Polishing powder is used to eliminate the uneven and cracked layers remaining after glass grinding through high-speed friction of the polishing disc on the glass surface to obtain a smooth and transparent glass surface. Those with high surface quality requirements can use the ultra-precision grinding and polishing method. Super-precision grinding and polishing uses special abrasives in a grinding and polishing fluid containing abrasives, which are pressed against the machined surface of the workpiece and perform high-speed rotation.

Polishing is to eliminate the processing marks on the surface of the lens after fine grinding, to achieve the final requirements of clean, transparent and correct diopter. Fine grinding and polishing using professional mold, punch processing concave surface of the lens, concave mold processing convex surface of the lens, mold surface curvature is basically the same as the curvature of the added lens. Chemical mechanical polishing is a polishing method that relies on cutting and plastic deformation of the material surface to remove the polished convex parts to obtain a smooth surface.

Inspection and storage

After the production of the lens is completed, it can be stored only after the top focus detection, optical center and prism degree detection, material and surface quality detection, specification and size detection, and packaging mark detection.

—-EDITOR: Doris Hu, Anna Wang

—POST: Doris Hu