Diamond tools for Optical

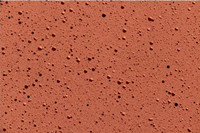

Milling grinding wheel

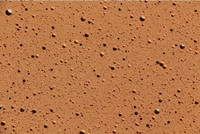

Centering wheel

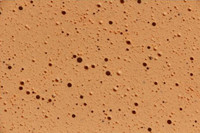

Diamond pellets

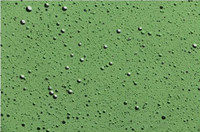

PU polishing pad

For optic lens, prism rough and fine grinding/polishing

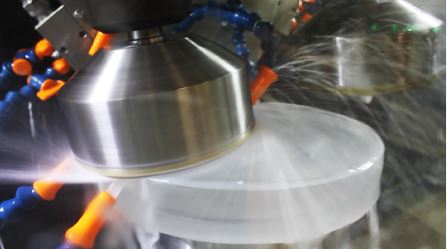

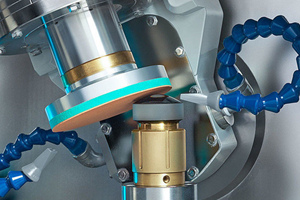

Milling grinding wheel for optic

Optic milling grinding wheels can grind optical elements blanks to form optical element prototypes with certain geometric shapes, dimensional accuracy, and surface roughness. Milling grinding wheel is ideal for the precision grinding of optical lenses (magnifying glasses, telescopes, cameras, etc.), eyeglass lenses, glass lampshades, and more.

Use metal diamond grinding wheel to grind the surface of the blank lens to produce the required radius, making it very close to the design radius, and reducing the thickness to 0.01 mm of the design thickness. .

Diamond pellets for polishing optics compents

Metal or resin bond with suitable grit and concentration diamond powder to make the diamond tools. Stick the diamond pellets with the substrates on the base.

Optic diamond pellets are used for optical manufacture, especially for lenses, mirrors, and prisms.

Diamond finish diamond pellets are mainly used for fine grinding optical glass, lens, ceramic, crystal, and optical elements after rough grinding, diamond pellets are usually use metal bond, and resin bonds are for fine grinding.

How to select grit for different optic components:

For the optical elements used in ordinary telescopes:

Generally only one step of metal-based 1200# or 1500# is required (the optical element surface roughness Ra value reaches 0.16~0.32μm), and then it can be transferred to polishing.

For microscopes, cameras and other instruments that have higher requirements for optical components:

First, use 1000# and 1200# metal bases for one stage of fine grinding, and then use 1500# or 1800# resin-based pellets. The piece undergoes a second pass of fine grinding (the surface roughness Ra of the optical element reaches below 0.10 μm).

Application of diamond pellets:

Diamond pellets can fine-grinding Lenses for optics, crystal lenses (sapphire, quartz, fluorite, etc.), ceramics, stainless steel, etc.

Features:

* Durable

* Provide high excellent cutting with no scratch

* Provide extra smooth and improve surface finishes.

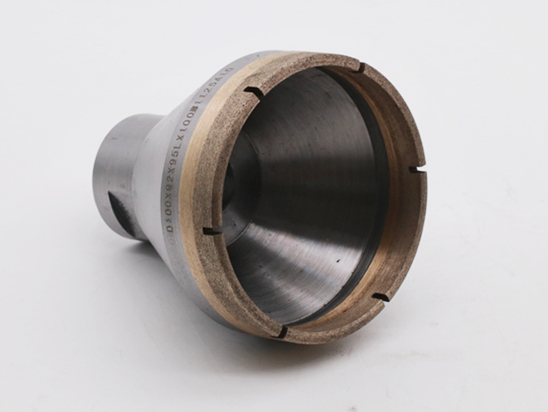

Centering wheels for optic

Centering wheel is used for rough and fine grinding optical lens, and performs. The lens centering required for high-precision lens systems requires, in addition to extremely high lens shape accuracy, the surface of the lens peripheral portion to be polished to 3 to 4 μm.

Diamond Wheels for optic

| D | d | H | R | T |

| 20 | 6 | 6 | 10 | 6 |

| 30 | 7 | 8 | 15 | 8 |

| 40 | 15 | 8 | 20 | 15 |

| 50 | 15 | 8 | 25 | 15 |

| 80 | 25 | 12 | 40 | 25 |

| 100 | 25 | 12 | 50 | 25 |

| 120 | 25 | 12 | 60 | 25 |

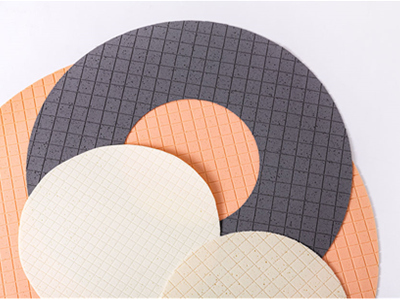

PU polishing pad for optic lens

What is PU polishing pad?

PU (Polyurethane) polishing pad is a polishing pad with high durability. After mixing polyurethane prepolymer, hardener, and foaming agent, it is poured into a shaping container to form a block, and then processed into a final sheet polishing pad through a slicing machine.

Application of polishing pad:

The lenses from the previous grinding process undergo final polishing to make the lenses transparent. The accuracy of the lens curvature is further improved to approximately 0.0003 to 0.001 mm depending on the pad polishing tool and polishing slurry used.

Moresuperhard LP series polishing pad for polishing precision optical components(lens, prism ), precision ceramics, wafers, metals, optical windows, optical glass, filters, optical crystals, etc…

The abrasive of the optic polishing pad has three types of filler:

–Zirconium Oxide polishing pad

–Cerium Oxide polishing pad

–Diamond polishing pad

Non-woven fabric type polishing pad

Non-woven polishing pads are used for first polishing of optical lenses, silicon wafers, semiconductor materials, metals, etc. A variety of soft to hard types are available to meet the quality requirements of cutting operations.

Aplication of Non-woven fabric type polishing pad

* For silicon and compound semiconductor wafers: First and final polishing

* For polishing optical lenses and various optical glass parts

* For polishing other materials, including plastic lenses, stainless and copper plates

Milling grinding wheel for optics

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Fillet radius (mm) | Abrasive width (mm) | Abrasive thickness (mm) |

| 28/33/38/ 43/53/63 | 55 | 18 | Customized | 1-7 | 1-7\ |

Centering grinding wheel for optical components

| D1 | D2 | D3 | h |

| 100 | 40 | 20 | 10 |

| 120 | 40 | 20 | 10 |

| 120 | 50 | 30 | 25 |

| 160 | 50 | 30 | 25 |

| 180 | 50 | 30 | 25 |

| 200 | 50 | 30 | 25 |

Diamond pellets for optic

| Type | Specification | Grit | Concentration | Radian | |

| Diameter | Thickness | ||||

| Finish Grinding Pellets(Metal) | 3-20mm | 2.5-10 | 180#-2000# | 75%-150% | upon request |

| Exceed Finish Grinding Pellets(Resin) | 3-20mm | 2.5-10 | 800#-3000# | 75%-150% | |

| Polishing Pellets(Resin) | 3-20mm | 2.5-10 | |||

PU polishing pad for optic

|

Model |

Filler | Average Density G / cm³ (Ib / ft³ ) | Average Hardness shore – A |

MSH- 66 |

cerium oxide | 0.42 (26) | 78 |

MSH- 77 |

cerium oxide | 0.43 (27) | 78 |

MSH- 13 |

cerium oxide | 0.35 (22) | 66 |

MSH- LASER |

zirconium oxide | 0.59 (37) | 90 |

MSH- 46 |

zirconium oxide | 0.40 (25) | 74 |

MSH- 26 |

zirconium oxide | 0.57 (36) | 88 |

MSH- 57 |

none | 0.51 (32) | 88 |

MSH- 87 |

none | 0.77 (49) | 96 |

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.