RELATED BLOG

-

Why CBN grinding wheel superior to Diamond wheel in Grinding Nitinol (NiTi)

2026-02-11 -

How to Choose the Right Grinding Wheel for Rubber Grinding

2026-01-29 -

How to Choose the Right Vacuum Brazed Diamond Tool

2025-12-17 -

How to Select the Right Polishing Pad Material for Different Sapphire CMP Stages

2025-12-07 -

Which Grit Wheel Should You Choose for Wood Turning Tools?

2025-12-04 -

Difference Between CVD Diamond Roller Dresser and Electroplated Diamond Roller Dresser

2025-11-18

-

Choose the right dresser for your tools

2019-11-23Dressing stones for grinding wheels are available in many different shapes. Choose from a single point diamond dresser with layered clusters, blade-type dressers with hand set diamonds, and grit dressers with uniform distribution of diamonds. Each dresser will give you a distinct finish. As you apply the grinding wheel dressing stick to the surface of your wheel, you’ll remove the top layer of the wheel and reveal a clean, sharp surface for future projects.

Learn More

-

Which Blade Is Right For You?

2019-11-23Diamond blade saws are more than capable of cutting a variety of materials, so begin by thinking about your needs. For instance, do you want a saw that will work with different things or one that works best with something specific, such as stone or granite.

Learn More

-

The Industrial Revolution

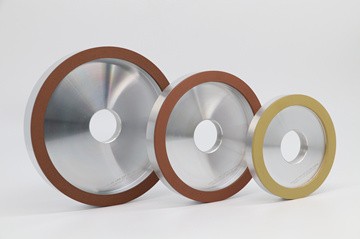

2019-11-23Today, development and use of these specialized tools have expanded to various industries, as demand never ceases and new applications are being discovered. One of the most demanded tools is the “resin-bonded wheel”, which is manufactured through the curing process of bonding diamond or CBN abrasives, with inorganic fillers, and using resins as binders, such as phenol and polymer. Resin bonded wheels are now effectively applicable to ail sorts of grinding operations such as surface grinding, cylindrical and centerless grinding, grooving and internal grinding, etc. It is ideally used for grinding super alloys, cermet, ceramic, glass, ferrite, high-speed steel, tool alloys, and many other new ultra-hard materials.

Learn More

-

Do and Don’t for Safe Grinding

2019-11-22Grinding wheels are safe tools when they are used in accordance with some basic rules.However if they are used incorrectly or not installed carefully onto the machine, there is the possibility that the grinding wheel may fracture.Learn More

-

Matching Resin Bond Grinding Wheels to the Workpiece

2019-11-22Superabrasive grinding wheels have two equally important components. While the grit, (diamond or CBN) does the work, it couldn’t function without a partner holding it in place. In the case of resin bond grinding wheels, that partner is phenolic resin.

Learn More

-

How to maintain your Diamond Grinding Wheel

2019-11-22Diamond wheels provide the maximum performance and high-speed cutting on demanding materials. Proper care and maintenance will ensure that the wheel gives the superior results for the maximum time. The steps are not difficult and well worth the effort.

Learn More

-

What Woodturners Need to Know about CBN

2019-11-16CBN wheels will even sharpen pure carbide bits and tools, although the life of the wheel will be compromised enough to probably not make it economically worthwhile. A wet CBN cutoff wheel will slice through carbide at the same speed as a diamond wheel, it just wears faster. Diamond is still the best abrasive for cutting pure carbide.If you are a fan of the newer powdered-metal woodturning tools (I know I am!) a CBN wheel is a must.Learn More

-

Metal bond Diamond/CBN honing stone

2019-11-16Metal bond Diamond/CBN honing oil stone is mainly used for fine grinding. It is suitable for fine grinding of automobile, diesel engine, motorcycle, tractor engine, the hydraulic cylinder bore of cylinder, hydraulic pump inner bore, cylinder block, valve, oil cylinder nozzle, compressor, air compressor cylinder hole and other series cylinder hole, blind hole, hole, the inner surface of the spline hole.Learn More

-

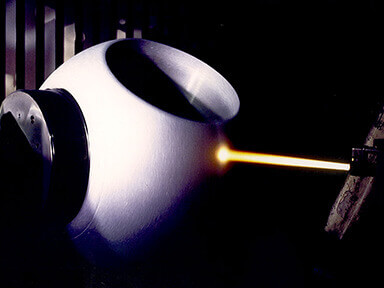

What is HVOF?

2019-11-16High Velocity Oxygen Fuel(HVOF) is a thermal spray system applied via a HVOF spray process using either a gas fuel or liquid fuel HVOF gun. When the fuel and oxygen mix, they combust and are able to be propelled out of the thermal spray gun at ultrasonic speeds! The HVOF process is what improves the bond strength and provides high density, high bond strength, optimum hardness, improved toughness, and higher coating thickness.Learn More

-

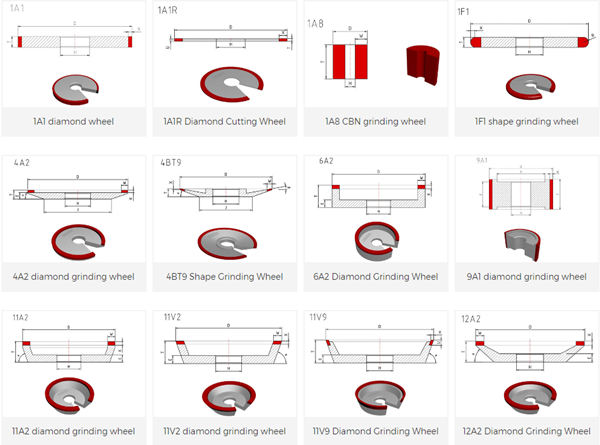

Choose the right Grinding Wheel – Sizes & Types

2019-11-16The diameter of a grinding wheel can range from just 1″ to 20″, they can go from just 0.035″ to up to 1/2″ thick. The smallest wheels are used for different operations like auto body work while the largest ones can cut through railway tracks and thick metal constructions.

Learn More