How to dresssing diamond grinding wheel?

Can a diamond grinding wheel be dressed?

Diamond grinding wheel can be dressed. The process of dressing diamond grinding wheel refers to refurbishing the grinding wheel surface by removing worn grains and exposing new, sharp abrasive particles. Dressing diamond grinding wheel can be dressed using diamond dressers, diamond roller dresser, electrochemical dressing or laser dressing, Dressing helps maintain and improve the grinding performance and wheel life.

What is dressing grinding wheel?

Grinding wheel dressing is the process of reshaping and cleaning the surface of a grinding wheel. The process is performed to ensure that the grinding wheel maintains its shape and that it is free from any debris or debris buildup that might affect its performance. There are several benefits to this process, including better grinding performance, longer wheel life, and a better finish on the workpiece.

The process of grinding wheel dressing involves using a special tool called a dressing stone or diamond dresser to reshape the surface of the grinding wheel. The dressing tool is held against the spinning wheel, and its abrasive material removes the surface layer of the wheel to reveal a fresh layer of abrasive grains. This helps maintain the shape of the wheel and prevents the formation of dull spots that can negatively impact its performance.

Grinding wheel dressing is also used to clean the wheel surface by removing accumulated debris and grinding swarf. This buildup can cause the wheel to become clogged, reducing its efficiency and causing the workpiece to overheat. By removing the debris, the grinding wheel can operate at peak efficiency, providing a better finish on the workpiece while extending its lifespan.

In conclusion, grinding wheel dressing is a critical process that helps maintain the shape and performance of grinding wheels. It ensures that the wheel maintains its sharpened edge and optimal efficiency, providing a smooth finish on the workpiece while increasing the lifespan of the wheel.

Dressing method for diamond grinding wheel

Diamond grinding wheels can be dressed using various methods to improve their performance and life. Based on the provided web results, common diamond wheel dressing techniques include:

* diamond roller dresser dressing using rotating cylindrical diamond dressers.

* Diamond stick dressing using straight diamond rods that are fed across the wheel surface.

* Electrochemical dressing using an electrolyte solution and electric current to remove wheel .material

* Laser dressing using a focused laser beam to evaporate and reshape the abrasive grains.

There are a few steps for dressing a diamond grinding wheel:

Mount the diamond wheel securely on the grinding machine. Ensure the wheel is balanced and runs true.

Turn on the grinding machine and adjust the speed to the recommended dressing speed for the wheel. Typically around 3500-5000 rpm.

Apply the dresser to the wheel surface. Dressers can be diamond roller dresser, sticks or plates.

Move the dresser across the wheel in a continuous motion. Apply light to moderate pressure. The aim is to remove the worn surface and expose fresh abrasive grains.

Check the wheel for a smooth surface and consistent exposure of grains. Redress as needed.

You will need to continue dressing the wheel periodically to maintain grinding performance during use. The dressing interval depends on factors like the material being ground and wheel wear.

How to dress a grinding wheel with a diamond dresser?

Dressing a grinding wheel is an essential process that is vital to maintaining performance and extending the lifespan of the wheel. One of the most efficient ways to dress a grinding wheel is by using a diamond dresser. Here are some steps on how to dress your grinding wheel with a diamond dresser:

* Mount the diamond dresser: The diamond dresser should be properly mounted on a holder or a tool rest. The dresser should be positioned at a height that allows it to easily contact the grinding wheel.

* Position the dresser: Move the dresser slowly towards the spinning grinding wheel, ensuring that it touches the wheel. The dressing process should be done with caution, to avoid any injuries or damage.

* Apply pressure: Once the diamond dresser is in contact with the wheel, apply sufficient pressure to the dresser. Move the dresser back and forth across the grinding wheel to remove any particles, debris or swarf.

* Clean the wheel: Once the dressing process is complete, use a clean rag to remove any debris or particles that remain on the grinding wheel surface.

* Test the grinding wheel: Run the grinding wheel at a low speed to ensure that it runs smoothly. Check for any signs of abnormal vibration or noise, which could signal an issue with the dressing process.

What is diamond roller dresser?

Proper and regular grinding wheel dressing is essential to maintain the shape and performance of your grinding wheel. By following these simple steps, you can reliably and efficiently dress your grinding wheel with a diamond dresser, maintaining its efficiency, and extending its lifespan.

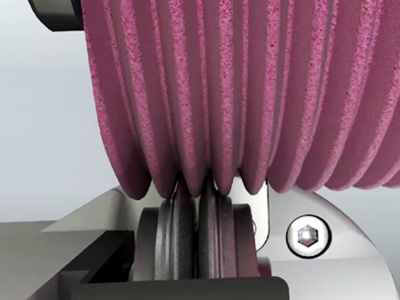

A rotary diamond dresser is a tool designed for dressing or reshaping abrasive grinding wheels. It is made up of a diamond-coated cylindrical rod that rotates on its axis. The rotating diamond dresser removes the surface layer of the grinding wheel by wearing it down, exposing a new layer of abrasive grains and reshaping the wheel to its optimal shape.

Diamond is widely used in the manufacturing of rotary diamond dressers due to its high abrasion resistance, toughness, and hardness. These properties allow for a long lifespan of the diamond dresser while providing the precision necessary to maintain the shape and sharpening of the grinding wheel.

Rotary diamond dressers are commonly used in a variety of industrial applications, including bearing and gear manufacturing, precision machining of engine and body parts, and cutting tools. The benefits of using rotary diamond dressers are numerous, including reducing cycle times, increasing efficiency, and improving the surface finish of the workpiece.

To use a rotary diamond dresser, the dresser is mounted on a holder and positioned so that it contacts the spinning grinding wheel. The dresser is then moved in a back and forth motion across the face of the wheel, removing any debris and reshaping the wheel to its optimal shape.

In conclusion, the rotary diamond dresser is an essential tool in industrial applications that require a high degree of precision and efficiency. Its use helps extend the lifespan of grinding wheels and maintains optimal grinding performance, providing a longer-lasting and better-quality surface finish on the workpiece.