How are vacuum brazed diamond tools made?

What are the advantages of vacuum brazed diamond tools?

In terms of performance, vacuum brazed diamond tools are similar to electroplated diamond tools. Generally, a single layer of diamond is attached to the surface of the substrate. It has a high diamond exposure rate and high cutting efficiency. It is also suitable for making special-shaped diamond tools. Products can be customized according to customer needs. More convenient. Through brazing, diamond is welded to the matrix instead of being simply wrapped, but chemically bonded. Therefore, the service life of brazed diamond tools is much longer than that of electroplated diamond tools. However, since the brazing process causes the matrix and diamond to experience high temperatures, and the matrix is prone to deformation at high temperatures, it also causes certain damage to the diamond. It is not suitable for small-sized tools that require high precision or are too thin or too thin. This is why brazing The main reason why welding cannot completely replace electroplating is that currently brazing diamond tools are more suitable for rough machining.

The biggest constraint in the vacuum brazing diamond process is the graphitization of diamond. Once diamond undergoes this transformation, it loses the required mechanical properties. The conditions for graphitization are a function of diamond type, oxygen content and temperature. , so brazing temperature and gas and oxygen control are the keys to limiting diamond graphitization.

Since the maximum brazing temperature can reach over 1000°C, diamond abrasive grains inevitably undergo thermal damage during the brazing process, which mainly includes graphitization of diamond abrasive grains, thermal stress and chemical erosion of diamond abrasive grains, which reduce their strength. , which in turn causes the abrasive grains to easily break and break during actual machining, or even the entire abrasive grain to fall off, seriously affecting the performance of the brazed diamond tool. In addition, residual stresses generated after high-temperature brazing can cause premature tool failure. Therefore, the brazing process parameters have a great influence on the performance of brazed diamond tools.

What are the vacuum brazing methods?

The main brazing methods include: high-frequency brazing, vacuum medium frequency brazing, shielding gas brazing, and vacuum brazing.

What are the differences between these brazing methods?

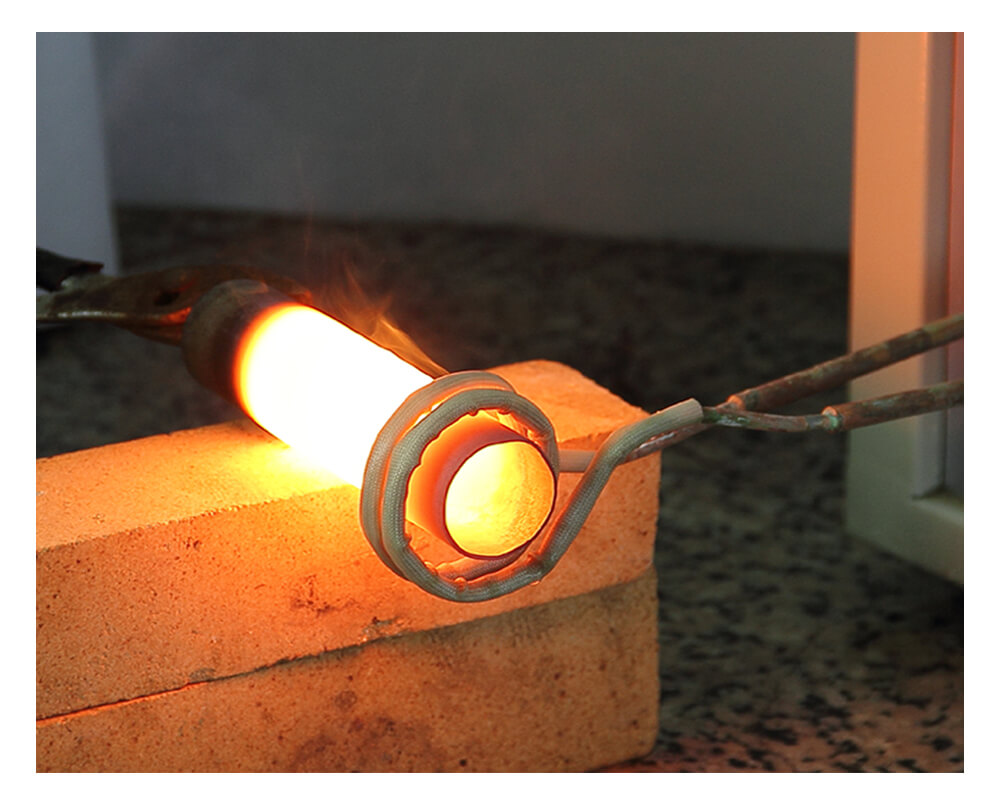

High frequency brazing:

The brazing time is short, but the high temperature will seriously damage the diamond. The matrix and the surface layer of the solder will also be oxidized, which will lead to a decrease in the holding power of the solder on the diamond.

Vacuum medium-frequency brazing

Because it is a vacuum environment, the brazing temperature is lower than that of exposed high-frequency brazing, and the effect is better than high-frequency brazing.

Brazing with shielding gas

The substrate and solder surface are not easily oxidized, but the cost is high.

Vacuum brazing:

The melting point of the solder in a vacuum environment is relatively low, and the temperature required for brazing is low, which can reduce damage to the diamond. The fluidity of the solder and the wettability of the diamond and the matrix are better than in other environments.

Solder

The bonding strength between diamond and matrix is determined by the brazing material. When brazing diamond tools, the brazing material does not mechanically wrap the diamond, but the brazing material generates a carbide on the surface of the diamond, which is a chemically strong combination. This requires The components of the solder must contain elements (Ti, V, Cr, etc.) that can form carbides with diamond at high temperatures.

Therefore, the general solder will contain about 10% chromium or titanium. The content of each element in the solder from each manufacturer is also different. There are powdery, flaky, silky, nickel-based, silver-based, The melting point of copper-based and nickel-based solders is generally above 900°C, and the melting point of silver-based solder is generally around 750°C.

For diamond, the lower the melting point of the brazing material, the better. However, if you want diamond to combine with metal elements such as chromium and titanium to form carbides, the reaction temperature is generally above 700°C, so the general brazing temperature is generally between 700 and 900°C.

During the high-temperature brazing process, the diamond abrasive grains need to be connected by the molten solder. The performance of the brazing material itself will largely affect the performance of the diamond brazing joint. In order to reduce the brazing temperature, the brazing material needs to have a lower At the same time, active element components need to be added to improve the wettability of the solder to the diamond abrasive grains, so that it can firmly connect the diamond abrasive grains to the tool matrix.

In addition, solder metal also has the following requirements:

1. The brazing material is required to have good wettability and bonding strength to diamond and matrix.

2. The brazing material should preferably not be corrosive or slightly corrosive to diamond.

3. The softening point of the brazing material must be higher than the local temperature of the brazing diamond tool during cutting and grinding.

What is flux?

Flux is an auxiliary material for soldering. It is similar to soldering flux. It mainly removes the oxide film on the surface of the solder and the base and improves the wettability of the solder to the surface of the base metal. If the solder used is of high purity, it will not be oxidized. The surface of the substrate is also very clean. Acetone, alcohol, and distilled water can also be used as “flux”

How should you choose diamond abrasives?

Like electroplated diamond, the higher the strength of the diamond, the better. Choose type three materials or type four materials.

Metal activation treatment is performed on the diamond surface to make the surface have metal-like properties, which is more conducive to the bonding between diamond and metal solder. Surface metallization mainly includes electroless plating plus electroplating, vacuum evaporation, plasma sputtering, magnetron sputtering, chemical vapor deposition, physical vapor deposition, mechanical coating, etc. The most commonly used methods are electroless plating plus electroplating and vacuum evaporation. . Metallization usually selects highly active metals, such as Ti, Cr, W, Mo, etc. Metal coating is conducive to the metallurgical bonding between diamond and matrix, and can improve the holding power of diamond particles by the diamond tool matrix.

Matrix

1. The softening point of the matrix must be higher than the melting point of the solder (generally the melting point of the steel matrix is 900°C)

2. The deformation amount of the substrate at high temperature must meet the working requirements

3. The matrix must have good affinity with the solder.

What are the steps in the production process of brazed diamond tools?

1. Sand cloth

Sand cloth is currently the key to brazing diamond tools, and it is also the key to determining whether a company or individual business can improve work efficiency and mass production. Except for some powerful manufacturers, most manufacturers currently operate by hand.

First use flux to make the solder into a paste, then use a thin metal sheet or a small brush to apply the solder on the substrate. The thickness and uniformity of the solder are all based on experience. Finally, sprinkle diamonds on the solder, but This purely manual method cannot guarantee the quality of brazed diamond tools

For mass production, spray gun spraying (similar to spray painting) can be used. The thickness of the solder is determined by the particle size of the diamond. It can be sprayed multiple times to increase the thickness.

2. Arrangement

Depending on the situation, use a variety of methods to sprinkle the diamonds on the brazing material evenly and in a certain regular arrangement. Generally speaking, diamonds above 50 mesh are required to be regularly arranged, and diamonds below 50 mesh are only required to be uniform.

Arrangement has an impact on the efficiency and life of diamond tools, and is also an important part. In addition, the coating of brazing material should not be too thick, which will result in a low diamond exposure rate, which is not conducive to cutting and grinding.

3. Drying

It is easy to oxidize and rust when placed in the air after spreading sand. It needs to be stored in a vacuum dryer furnace, pre-dried, or directly brazed. However, direct brazing will have certain harm to the brazing furnace and the pump oil. pollute.

4.Brazing

The temperature is adjusted according to the solder material (based on the melting point temperature provided by the manufacturer of the missing material) and the vacuum degree of the own equipment. There are many things that need to be paid attention to during the brazing process, and they all need to be based on the specific situation.

Identify whether brazing is successful:

1. Check how well the diamond is wrapped by the solder material, and whether the solder material has climbed to the highest point of the diamond.

2. Use a sharp metal to tap the diamond to see if it can be easily knocked off. If it can be easily knocked off, it means that the solder material does not hold the diamond well.

- Sampling experiment is the most effective way to inspect products

Aplication of vacuum brazed diamond tools

Vacuum brazed diamond drill bit

Vacuum brazed diamond drill bits are suitable for cutting, and dry drilling various hard non-ferrous materials, such as marble, granite, glass, ceramics, hard concrete and bricks. The cutting surface is smooth and the cutting speed is high.

Vacuum brazed blades are suitable for cutting granite, marble, aluminum, Cast Iron, copper pipe, corrugated Roofing, drywall, ductile iron pipe, fire door, masonry, steel Metal, stucco, wood,etc

Vacuum Brazed diamond bur used for dry/wet grinding Used for cast iron, grey iron, metal profile, marble, granite, quartz, stone, ceramics, and glass, etc.

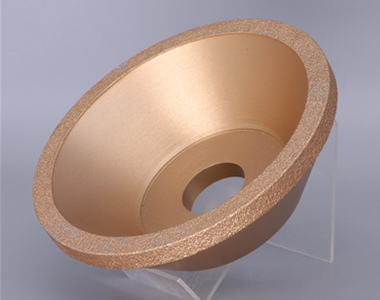

Vacuum Brazed Diamond flat grinding wheel

Vacuum Brazed Diamond flat grinding wheel used for grinding shaping or Beveling granite & marble concrete artifical stone masonry ceramic,etc. Also available for cutting or grooving.

Moresuperhard vacuum brazed diamond tools for cutting, grinding, drilling foundry, metal working, composites, automotive sector,cast iron, angle iron, ductile iron, carbon steel,etc.

—-EDITOR: Doris Hu, Anna Wang

—POST: Doris Hu