Difference Between CVD Diamond Roller Dresser and Electroplated Diamond Roller Dresser

Recently Moresuperhard received one feedback about CVD diamond dressing tools not working well in dressing Al2O3 abrasive grinding wheel, lets see the reason together:

|

Problems customer feeback |

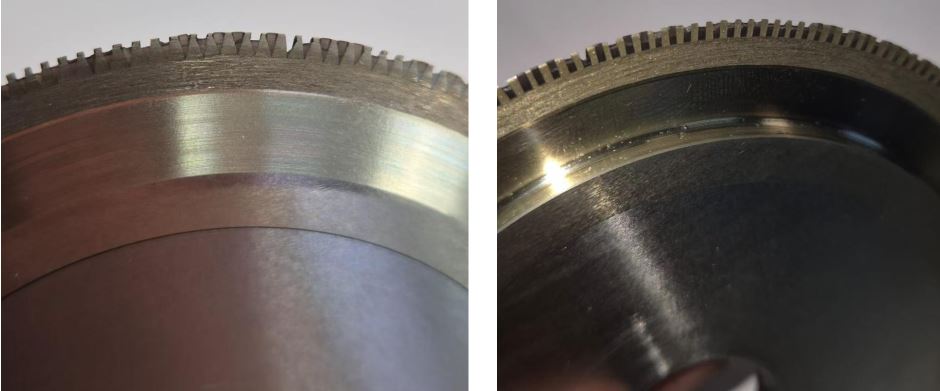

The customer mentioned that one of the two CVD diamond rollers they purchased a second time had developed a severe chip. After inspecting the roller, our first thought was that improper operation by the customer had caused the roller to fail, resulting in a large and relatively regular chipping pattern. |

| Moresuperhard solutions | We told the customer that this was likely caused by improper operation and asked if they could confirm with their operator whether it was indeed due to improper operation. We also assured the customer that we have comprehensive after-sales service and would provide compensation if there were no issues, to reassure them.

The customer replied the next day: “I confirmed with the operator. We are dressing a ceramic grinding wheel at 2500 rpm, and the dressing machine is running at 6200 rpm. The dressing depth is 0.02 mm per cycle. The picture below shows the grinding wheel we are dressing. The customer also mentioned that the problem only occurred when dressing this particular grinding wheel.” |

Upon inspection, the grinding wheel was found to be a resin-bonded wheel, which is why the customer explained that CVD diamond rollers can only be used for ceramic-bonded grinding wheels not suitable for BFAG abrasive wheel. Upon inspection, the grinding wheel was found to be a resin-bonded wheel, which is why the customer explained that CVD diamond rollers can only be used for ceramic-bonded grinding wheels not suitable for BFAG abrasive wheel.

|

|

| Customers: Good morning, I do not agree much about not being able to dress this grinding wheel, because it is a ceramic grain grinding wheel, and I have been using this type of grinding wheel for a long time, using dresser with electrolyte diamond.

(It’s clear from the customer’s and our statements that we’re referring to different types of ceramics. I was talking about ceramic bond, but the customer was referring to ceramic grain. Based on the photo of the grinding wheel the customer sent, it appears to be an A-grade brown fused alumina grinding wheel. Brown fused alumina’s main component is alumina, which is also a type of ceramic, hence the misunderstanding.)

|

|

| Customers final feedback

Good night, I understand, you’re talking about resin and not grain. I understand, I think you are right, so it happened only when I put it on this wheel. I had already put it on other wheels and the work was normal. I didn’t know I couldn’t use this dresser on this kind of grinding wheel. Thank you for teaching me about it. Not at all. You cannot be responsible for a problem caused by us |

Types of Rotary Diamond Dressers

Rotary diamond dressers are categorized based on manufacturing method, diamond structure, and cutting behavior.

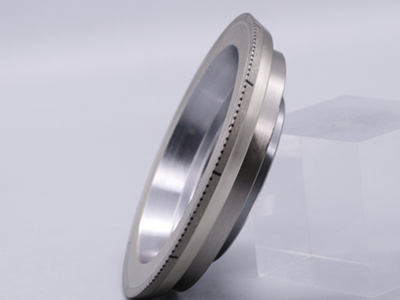

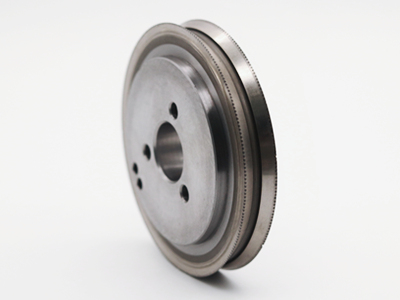

Electroplated Diamond Roller Dresser

-

Single-layer diamond grains held by nickel plating

-

High diamond protrusion (sharp cutting action)

-

Good for a wide range of wheel bonds: vitrified, resin, hybrid

-

Can be re-plated

-

More aggressive cutting, lower dressing force

Applications:

Cylindrical grinding, centerless grinding, resin CBN wheels, camshaft/cam lobe wheels, tool grinding wheels.

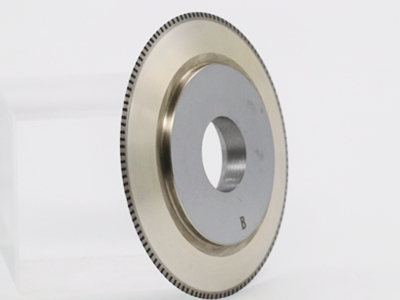

CVD Diamond Roller Dresser

-

Diamond layer created by Chemical Vapor Deposition

-

Forms a continuous polycrystalline diamond film

-

Extremely wear-resistant and dimensionally stable

-

Highest profile accuracy

-

Only suitable for brittle-bond wheels

Applications:

Vitrified CBN wheels, vitrified alumina wheels, automotive precision grinding, bearing raceway grinding.

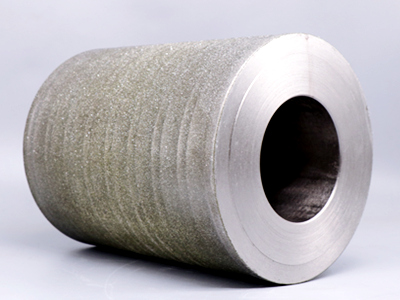

Sintered Diamond Roller Dresser

-

Diamond grains distributed in a sintered metal matrix

-

Multi-layer structure

-

Strong but less precise than CVD/electroplated

-

Suitable for more durable dressing jobs

Applications:

Heavy-duty dressing, rough form correction.

Why CVD Diamond Roller Dressers Work for Ceramic Bond Wheels but Not Resin Bond Wheels

CVD Diamond Roller Dresser

-

Produced by Chemical Vapor Deposition

-

Forms a continuous polycrystalline diamond (PCD) layer

-

Diamond film grows directly on the roller substrate

-

No abrasive grit; it’s a single, uniform diamond coating

Result:

Extremely high wear resistance, high accuracy, stable shape retention.

CVD roller dressers are designed for crush dressing, where the diamond roller fractures the bond material and exposes fresh abrasive grains. Their success depends on the grinding wheel’s bond behavior under pressure.

Let’s analyze both wheel types.

Ceramic (Vitrified) Bond Grinding Wheels — Compatible with CVD

Ceramic bonds are:

-

Hard

-

Brittle

-

Micro-fracturable

-

Thermally stable

When a CVD roller dresser contacts a ceramic wheel, the brittle bond fractures cleanly:

-

Sharp diamond edges break the vitrified bond

-

Fresh grains are exposed

-

Wheel profile is restored quickly

-

Dressing forces remain stable

Therefore:

✔ CVD rollers excel at dressing vitrified (ceramic) bond wheels

Such as:

-

Vitrified alumina wheels (WA, PA, BFA, GC)

-

Vitrified CBN wheels

-

Vitrified diamond wheels

This is why CVD dressers dominate bearing, camshaft, crankshaft, and precision automotive grinding processes.

Resin Bond Grinding Wheels (BFA Abrasive) — NOT compatible with CVD

Resin bond wheels behave completely differently.

Resin bonds:

-

Are soft and elastic

-

Tend to smear and melt at dressing temperatures

-

Deform instead of fracturing

-

Have low brittleness

-

Exhibit strong rebound under impact

Brown fused alumina (BFA):

-

Tough (low friability)

-

Difficult to micro-fracture

-

Needs sharp and aggressive dressing action

When a CVD roller attempts to dress a resin wheel:

-

Resin smears over the diamond surface

-

The bond does not fracture

-

Diamond film gets loaded or glazed

-

Dressing forces increase rapidly

-

Risk of dresser overheating or cracking

-

Wheel does not become sharp

This makes CVD roller dressing not only ineffective but also damaging.

Therefore:

❌ CVD diamond rollers cannot dress resin bond wheels, especially those using BFA abrasives.

Why Electroplated Diamond Rollers CAN Dress Resin Bond Wheels\

Electroplated Diamond Roller Dresser

-

Uses single-layer diamond grains

-

Diamond particles are fixed by nickel electroplating

-

High protrusion (30–40% of grit height)

-

Diamond grains are sharp and exposed

Result:

Very sharp cutting action, high material removal, aggressive dressing.

Unlike CVD rollers, electroplated diamond rollers have:

-

Very high diamond grit protrusion

-

Sharp cutting edges

-

Larger chip pockets

-

Lower dressing pressure

-

Higher self-sharpening action

During dressing:

-

Resin is cut, not crushed

-

Soft bond materials are removed cleanly

-

Abrasive grains (BFA, CBN, diamond) are exposed properly

-

Heat generation is lower

-

No smearing or glazing occurs

This is why electroplated rollers can dress:

✔ Resin bond diamond wheels

✔ Resin CBN wheels

✔ Resin alumina wheels (including BFA)

✔ Hybrid and polyimide wheels (if not too elastic)

And this is the key difference in real-world performance.

| Feature | CVD Diamond Roller Dresser | Electroplated Diamond Roller Dresser |

| Diamond Structure | Continuous CVD-grown diamond film (PCD layer) | Single-layer diamond grit fixed with nickel plating |

| Dressing Mechanism | Crush → fractures brittle bond | Cutting → removes bond (resin or ceramic) |

| Diamond Protrusion | Low | High (sharp, aggressive cutting) |

| Cutting Sharpness | Medium | Very high |

| Wear Resistance | Extremely high (longest lifespan) | Medium (can be replated) |

| Dressing Force | High | Low (suitable for soft bonds) |

| Heat Generation | Higher | Lower |

| Suitable Wheel Bonds | ✓ Vitrified/ceramic bonds ✓ Brittle metal bond wheels |

✓ Vitrified/ceramic bonds ✓ Resin bond wheels ✓ Hybrid bonds ✓ Dressable metal bonds |

| Not Suitable For | ✗ Resin bond wheels (BFA, CBN, Diamond) ✗ Rubber bond wheels |

✗ Very soft rubber wheels ✗ Extremely dense/ultra-hard metal bonds |

| Profile Accuracy | Excellent | Good |

| Replating / Reuse | No | Yes |

| Equipment Adaptability | High-end production lines, precision form dressing | More universal, flexible for multiple bond types |

| Cost | High | Medium |

| Typical Applications | Automotive camshaft/crankshaft grinding Bearing raceway grinding Vitrified CBN/diamond wheels |

Resin CBN/diamond wheels Centerless/cylindrical grinding Tool & cutter grinding |

—EDITOR: Doris Hu, Cris Zhang

–POST: Doris Hu