Case of brazed cutting disc for CFRP material

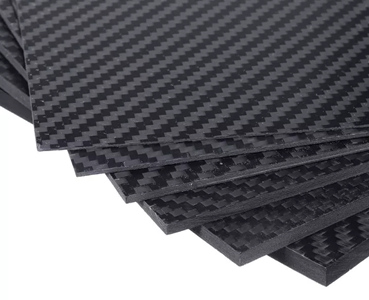

What is CFRP ?

Carbon Fiber Reinforced Composite is called Carbon Fiber Reinforced Polymer (CFRP). Carbon fiber refers to the high strength and high modulus fiber with more than 90% carbon content. High temperature resistance in the first of all chemical fiber. With acrylic fiber and viscose fiber as raw materials, through high temperature oxidation carbonization. It is an excellent material for manufacturing aerospace and other high-tech equipment.

Carbon fiber is mainly composed of carbon element, with high temperature resistance, friction resistance, thermal conductivity and corrosion resistance characteristics of fiber shape, soft, can be processed into a variety of fabrics, because its graphite microcrystal structure along the fiber axis preferred orientation, so along the fiber axis direction has a high strength and modulus. The density of carbon fiber is small, so the specific strength and modulus are high.

Application of CFRP:

The main use of Carbon Fiber Reinforced Composite is as a reinforced material and resin, metal, ceramic and carbon composite, manufacturing advanced composite materials. The specific strength and modulus of carbon fiber reinforced epoxy resin composites are the highest among existing engineering materials.

Carbon fiber is ideal for high-load structures in aerospace, automotive, entertainment, and medical applications. Carbon fiber is also widely used in the wind power, energy and chemical industries.

Carbon fiber composite is composed of carbon fiber reinforced material and resin as matrix material.

Carbon fiber is used in the car frame, seat, cabin cover, drive shaft, rearview mirror and other car body, automotive carbon fiber has several advantages:

Lightweight: The current hot electric vehicle, due to the short range of battery technology has become a bottleneck restricting its development, can only be solved from the body structure and material replacement. Carbon fiber composites weigh half as much less than steel and a third less than aluminum, and the immediate impact is longer range and more energy saving

Comfort: The soft tensile performance of carbon fiber can improve the noise and vibration control of the whole vehicle, which will greatly improve the comfort of the car.

Reliability: Carbon fiber has higher fatigue strength, good collision energy absorption, while reducing the weight of the vehicle can also maintain the strength and safety, reducing the safety risk factor caused by lightweight.

Improve life: some parts of the car require corrosion, to pass the test of high temperature, low cold, smoke, ordinary metal parts can not guarantee the service life in different environments. Carbon fiber is free of corrosion and rust, which enhances the life of car parts.

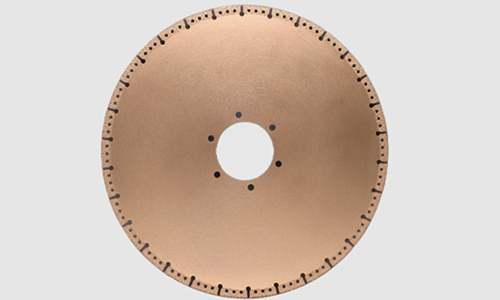

Recently, a customer from Spain needs brazing cutting blades, the enquiry is as follows:

| Grit of vacuum brazed diamond cutting disc | D301 (vacuum brazed) |

| Cut workpiece | Carbon fiber |

If you have requirements of cutting CFRP material, you can choose vacuum brazed cuttnig disc. High precison requirement can contact our sales Miss Wing by email wing@moresuperhard.com to talk in detail.

—EDITOR: Doris Hu/ Wing She

—POST: Doris Hu