Application of honing process in automobile parts manufacturing

Honing is a method of finishing workpiece surface at low cutting speed. It is a special form of grinding and an efficient machining method in finishing machining.

Honing Process is not only a special form of grinding, but also a machining method in finishing machining. This process can not only remove large machining allowance, but also is an effective machining method to improve the dimension accuracy, geometric shape accuracy and surface roughness of parts. It is widely used in automobile parts manufacturing. Honing is a method of finishing workpiece surface at low cutting speed. It is a special form of grinding and an efficient machining method in finishing machining.

Honing process principle

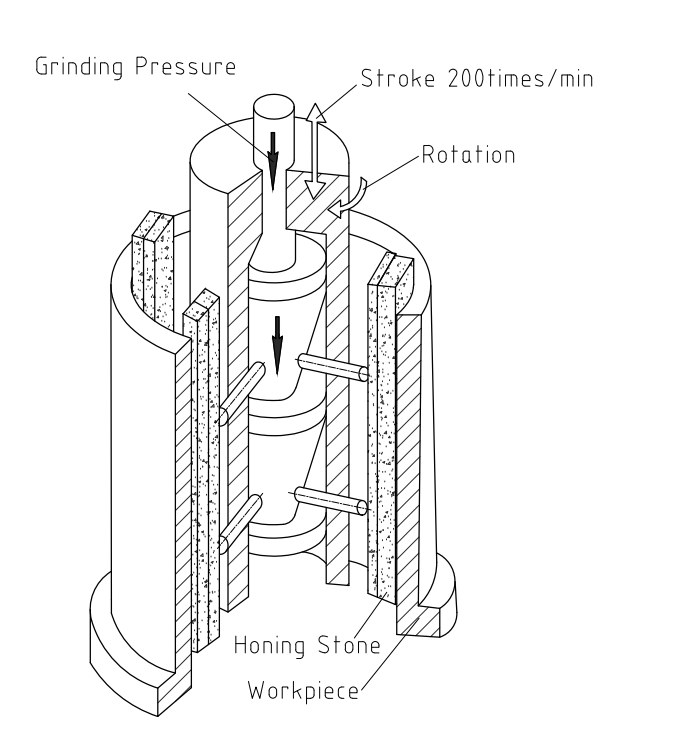

Honing is to use one or more oil stones installed on the circumference of the honing head, and expand the oil stones radially by the expansion mechanism (including rotary and propelling) to press the oil stones towards the hole wall of the workpiece, so as to produce a certain surface contact. At the same time, make the honing head rotate and reciprocate, and the parts do not move. Or the honing head only rotates and the workpiece reciprocates, so as to realize honing.

In most cases, the honing head is floating between the machine tool spindle or between the honing head and the workpiece fixture. In this way, the honing head is guided by the hole wall of the workpiece during machining. Therefore, the machining accuracy is less affected by the precision of the machine tool itself, and the formation of the hole surface basically has the characteristics of the creation process. The so-called creation process is the grinding and dressing of the pore wall and the surface of the whetstone. The principle is similar to that of two flat plates moving in plane.

Superhard honing stones are bonded abrasives made of diamond or CBN(cubic boron nitride abrasives). The grinding efficiency and grinding quality of super hard honing stone are very good, the grinding time is shortened, and the pass rate of workpiece is improved. The life of oil stone is greatly extended, thus changing the situation that the amount of work, frequent adjustment and frequent replacement of oil stone are needed, and the productivity is greatly improved. At the same time, using water and a small amount of antirust agent instead of antirust oil as coolant, can save a lot of oil, so as to reduce the processing cost of products. Diamond or cubic boron nitride whetstone can be honed with any material, including a variety of steel, carbide, cast iron, ultra-heat resistant alloys, electroplated and coated coatings, ceramics, and glass. The various properties of the superabrasive whetstone can be reproduced stably because the superabrasive whetstone, regardless of its formulation, can be hot-pressed to close to 100 percent density (metal binder), thereby reducing the change in properties due to closed pores.

In the honing process, as the honing head rotates and reciprocates or the workpiece rotates and reciprocates, the cutting track of the machining surface fork helix is caused, and the number of revolutions of the honing head within each reciprocating stroke time is not an integer. Therefore, between two strokes, the honing head diverges a certain Angle in the circumferential direction relative to the workpiece, so that the movement track of each abrasive particle on the honing head on the hole wall will not repeat. In addition, for each turn of honing head, there is an overlap length on the axis between the cutting track of the oil stone and the previous one, which makes the connection between the grinding track before and after more smooth and even. In this way, each point of the hole wall and the stone surface will interfere with each other almost equally throughout the honing process. As honing hole surface and, therefore, oil stone surface continuously produce interference point, to put these interference point grinding and generate new interference of more points, and continuous grinding, make the hole and sharpening stone surface contact area is increased, the degree of mutual interference and cutting effect weakening, holes and oil-stone roundness and cylindricity also constantly improve, after completing the process of initiative on the surface of the hole. In order to obtain better cylindricity, it is often possible to turn around parts or change the axial position of the honing head and the workpiece.

As abrasive materials such as diamond and cubic boron nitride are used in honing oilstone, the wear of oilstone is very small in machining, that is, the amount of dressing of oilstone by workpiece is very small. Therefore, the precision of the hole depends to some extent on the original precision of the oil stone on the honing head. So when diamond and cubic boron nitride whetstone are used, the whetstone should be well trimmed before honing to ensure the accuracy of the hole.

Honing processing characteristics

(1) High machining accuracy

Honing can improve the shape accuracy of the workpiece to be machined, especially for some small and medium-sized through holes, whose cylindricity can be less than 0.001mm. Some non-uniform wall thickness parts, such as con

necting rod, its roundness can reach 0.002mm, if there is no ring groove or radial hole, straightness up to 0.01mm/1m is also possible. Honing is more accurate than grinding. During grinding, the bearing supporting the grinding wheel is located outside the grinding hole, which will cause deviation, especially for small hole machining.

(2) Good surface quality

The surface is interlaced, which is good for lubricating oil storage and oil film maintenance. It has a high surface support ratio (the ratio of the actual contact area between the hole and the shaft and the matching area between the two), so it can bear a large load and wear resistance, thus improving the service life of the product. As the honing speed is low, and the oil stone is in surface contact with the hole, the average grinding pressure of each abrasive grain is small, so the heat of the workpiece is very small, the temperature of the cutting area can be kept at 50-150℃, and the workpiece surface almost has no thermal damage and metamorphism layer, and the deformation is small.

(3) wide range of processing

The main processing of various cylindrical holes: through hole, axial and radial discontinuous hole, such as radial hole or slot, keyway hole, spline hole, blind hole, multi-step hole, etc.. In addition, special honing head can also be used to process tapered holes, oval holes, etc., but due to the complex structure of honing head, generally not. Cylindrical honing can be honed with an outer round honing tool, but the amount of allowance removed is much less than that of the inner round honing.

(4) small cutting allowance

Honing machining is one of the machining methods with the least amount of removal allowance. In honing process, the honing tool is guided by the workpiece to cut off the excess of the workpiece to achieve the desired accuracy.

(5) Strong ability to rectify holes

Due to the shortcomings of other processing technology, there will be some of the following processing defects in the process of processing: such as loss of circle, bell mouth, corrugated hole, small size, waist drum shape, taper, boring cutter grain, hole partial and rough surface. Honing can greatly improve dimensional accuracy, roundness, straightness, cylindricity, and surface roughness of holes and outer circles by removing minimal machining allowance.

More Superhard provides precision bore honing finishing solution, the honing tools include Diamond honing stone, cbn honing stick, Single pass diamond honing tools, Cylinder honing tools, Diamond honing head, Diamond cylinder hone,

Can match honing machine: Sunnen, Nagel, Gehring, Nissin, Engis, Fuji, Mas and other honing machines.

—-EDITOR: Doris Hu

—POST: Doris Hu