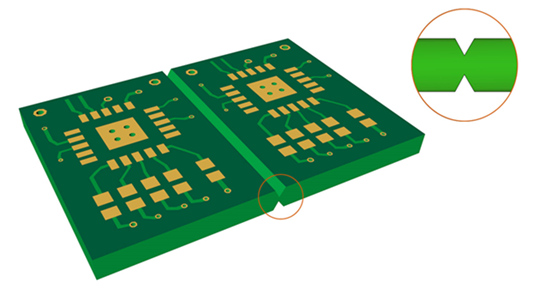

Diamond dicing blade cutting PCB

PCB is printed circuit board, short for printed board, is one of the basic components of the electronic industry. PCB is used in almost all electronic devices, from electronic watches and calculators to computers, communication electronic devices and military weapon systems. As long as there are integrated circuits and other electronic components, PCB should be used in order to make the electrical interconnection between each component.

Case of Wafer dicing blade for didicing PCB

Dicing parameters

| Material | 1.2mm thick resin containing copper layer |

|

Cutting requirements |

1)Cutting without burrs

2)Incision perpendicularity < 0.005mm 3)Cutting dimensional error < 0.02mm 4) Snake cutting is not allowed |

Cutting machine Cutting machine |

Disco DAD3350 scribing machine |

| Diamond dicing blade | Metal Diamond dicing blade 58Dx0.15Tx40H(Grit 400#) |

Cutting parameters

| Cutting direction | Straight cutting |

| Spindle speed | 30000rpm |

| Feed speed | 50mm/S |

| Cooling water | pure water |

Common dicing problems and solutions

1) Dicing dimension exceeds tolerance

There is an error in the thickness of the blade, resulting in a deviation in the size of the dicing workpiece. It is necessary to recalibrate the position of the blade and adjust the cutting size within the qualified range.

2) Dicing perpendicularity out of tolerance

The main reasons for cutting verticality out-of-tolerance are:

(1) Uneven clamping, blade edge has a skew;

(2) Blade edge wear, edge trapezoid.

If the reason (1)need to clean the flange re-clamping blade, to ensure that clamping smooth ;If the reason (2) need to replace the blade.

3) Snake Dicing

The main reason of serpentine cutting is that the cutting blade becomes blunt. It can be used to cut the blade again to improve its sharpness and solve the problem of serpentine cutting.

4) Dicing produces burrs

The main causes of burrs include:

(1) Blunt blade wear;

(2) The edge is worn and deformed, resulting in rounded corners.

Above two reasons all need to repair the blade, make the blade edge repair flat, and expose the new abrasive grain, improve the sharpness of the blade, so as to reduce burrs.

conclusion

The metal bond diamond disco blade for wafer is one of the characteristic products of Siter technology, and its production technology is mature and stable, making it unique in the domestic industry.Xist metal soft knife cutting PCB without burr, high dimensional accuracy, good cutting stability, long life, high cost performance, favored by the majority of users.