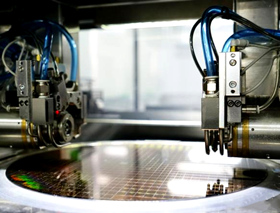

Diamond Dicing Blade for semiconductor industry

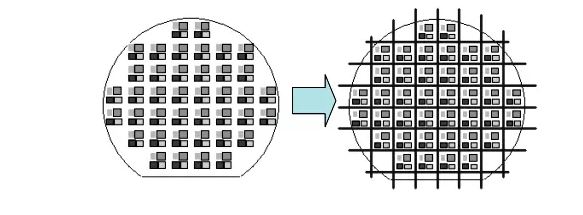

Generally, the dicing blade is made of synthetic resin, copper, tin, nickel and so on, which are combined with artificial diamond as binder. It is mainly divided into two categories: hard cutter with wheel hub and integral cutter without wheel hub. It is suitable for processing chips and semiconducting materials of different types.

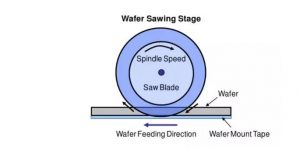

In the processing of products, the diamond particles will fracture under the impact of the product and re-form sharp edges and corners to ensure its sharpness. In the cutting process, the original binding agent of diamond particles is constantly worn. Driven by the force, the diamond particles fall off, exposing the new particles below, so that it can guarantee the sharpness of the blade.

Six factors affecting the quality of semiconductor dicing blade :

1. Influence of diamond particle size:

(1) Large particles:

1. The edge is large, the debris removed is much, and the product is not easy to accumulate and precipitate silica powder.

2. The contact surface with the binder is large, can withstand resistance, high processing efficiency, not easy to wear.

3. The contact range with the product is large, the debris and collapse produced and the cutting quality is poor.

(2) Small particles:

1. Small contact range with the product, small debris and collapse or even no collapse.

2. Small knife edge, less removed debris, easy deposition of silicon powder products.

3. The contact surface with the binder is small, can bear small resistance, low processing efficiency, easy to wear.

2. The influence of binder strength:

(1) High strength binder:

1. Diamond cicing blades have advantages :strong toughness, not easy to break, high utilization rate.

2.The wear resistance is strong, blade regeneration ability is weak, product quality is poor.

3. Large resistance, slow feed speed, low efficiency.

(2) Low strength binder:

1. Small resistance, fast feed speed and high efficiency.

2. Easy to wear, blade regeneration ability is strong, product quality is good.

3. Weak toughness, easy to break the knife, low utilization rate.

3. Influence of particle concentration

(1) High concentration:

1. More edge, more removed debris, the product is not easy to silicon powder residue.

2. Diamond particles have small load, small cutting resistance, fast progress and high efficiency.

3. The product has small knife edge, small debris, easy washing and guaranteed quality. Four is less binder, blade toughness is low, easy to break the knife, scratch the product risk.

2) Low concentration:

1: Binder, high toughness of the blade, not easy to break the knife.

2: Less knife edge, less removed debris, easy silicon powder residue.

3: Diamond particle load, cutting resistance, slow progress, low efficiency.

4. Influence of blade thickness

(1) Blade thickness:

1: Blade vibration is small, product quality is guaranteed.

2: Strong blade strength, not easy to break the knife.

3: Cutting contact area, resistance, debris, feed speed is slow, easy to pollution.

(2) Thin blade:

1: Cutting contact area, small resistance, fast feed speed.

2: Blade vibration is small, product quality is guaranteed.

3: The blade strength is weak, easy to break the knife.

5. Influence of blade length

(1) Blade length:

1: Long service life.

2: Weak blade strength, slow feed speed, easy to break the knife.

3: Vibration, prone to deflection, cutting snake.

(2) Short blade:

1: Short service life.

2: Strong blade strength, fast feed speed, not easy to break the knife.

3: Small vibration, not easy to occur, good quality.

6. The impact of blade sharpening link

The purpose of sharpening the blade is to expose the diamond on the blade surface and correct the eccentricity of the blade and the hub and flange. When the new blade is installed on the spindle and flange, although the blade is in direct contact with the top of the spindle, there is still a gap between the two, which is the “eccentricity” of the blade. By grinding the blade, it can not only better expose the diamond, but also correct the “concentricity” of the blade and the tool rest. If the blade is used in the case of “eccentricity”, only part of the blade works, the load is too large, easy to cause reverse blade and overload, affecting product quality.

—EDITOR: Doris Hu

—POST: Doris Hu