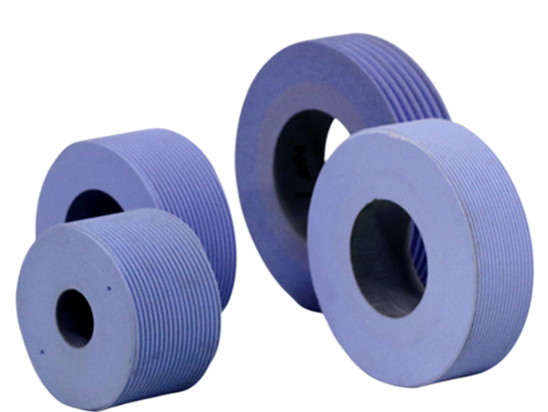

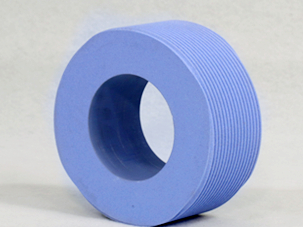

Worm gear grinding wheel

SG grinding wheel for worm shaft/ electropalted diamond/CBN profile grinding wheel

Continuous generative grinding/ Profile grinding

Match grinding machine: KAPP, Haas,MonnierZahner, SAMP,Gleason,Felsomat,etc

Also match diamond rotary diamond dresser for worm grinding wheel

All sizes can customize according to your reqirment

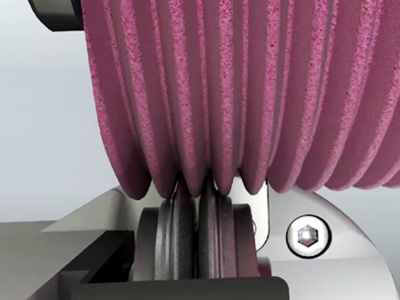

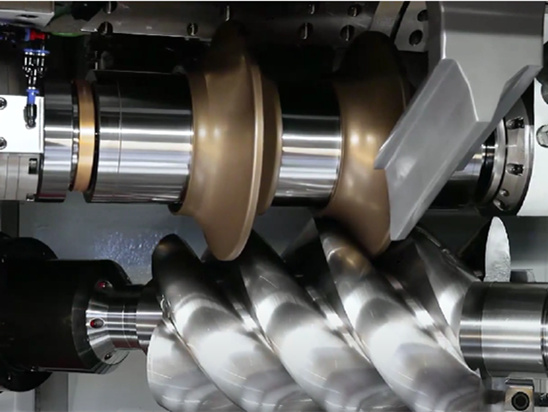

Continuous Worm Grinding

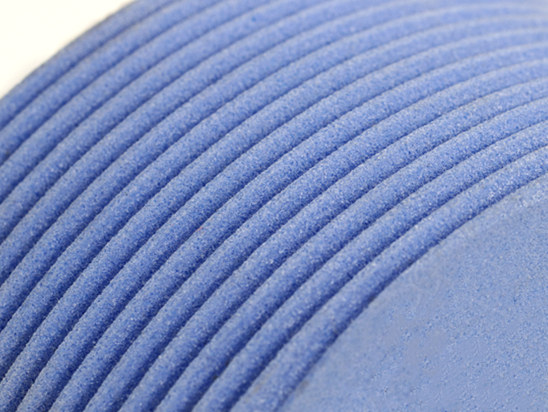

The worm grinding wheel has a high speed and continuous grinding, so the production efficiency is very high. The grinding accuracy is generally grade 5, up to grade 3, which is very suitable for the finishing of gears produced in large and medium batches. The continuous worm grinding wheel is mainly used for grinding the worm gear and worm gear surface of the reducer, so it is widely used for grinding of small and medium size gear, especially the grinding of mass gear.

Moresuperhard worm grinding wheel adopts high-performance ceramic abrasives, which can effectively reduce the grinding force and improve the surface quality. The special pore structure design makes the uniformity and consistency of the grinding wheel better. The excellent shape retention makes the dressing interval of the grinding wheel longer, which can be very effectively help customers improve production efficiency.

Worm thread grinding wheel

Advantages of Moresuperhard worm gear grinding wheel

* Reduce the grinding force and improve the surface quality

* High uniformity and consistency of the grinding wheel

* Excellent shape retention improve production efficiency

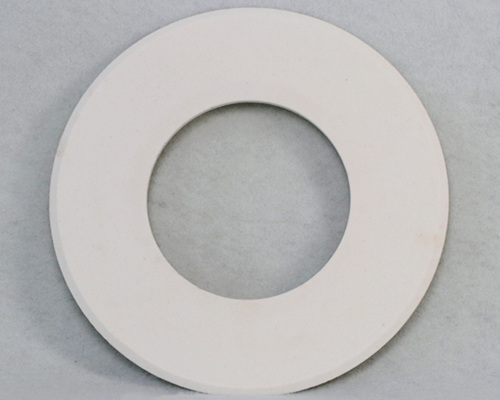

How to dressing worm grinding wheel

* With the heat-treated hardened steel substrate as the substrate, the surface accuracy of the roller can be maintained for a long time

* The steel substrate of the plated roller needs to be pre-formed in advance on the surface of the steel substrate to be plated. After electroplating and sanding, a small amount of trimming can meet the extremely high tooth profile accuracy requirements, and the damage to the diamond particles is minimal, and the roller has high durability.

* Large amount of abrasive material, sharp edge of the roller, high efficiency of dressing the grinding wheel, and the surface of the grinding wheel has a space for liquid and chip removal, which is not easy to burn the workpiece

* The grinding resistance between the dresser and the grinding wheel is only 1/3~1/2 of that of other process rollers, which can effectively protect the machine tool dressing shaft from damage and loss of precision

* Good transmission stability and low transmission noise.

Case of worm grinding wheel for worm shaft grinding

| Workpiece material | 20CrMnTi |

| Requirement of surface roughness | Ra=0.6 |

| pressure angle | 20° |

| Hrardness of workpiece | HRC58~62 |

| Size of worm grinding wheel | 280*160*115 |

| Grinding time | 4min |

| Dressing amount | 0.25mm |

| Dressing interval | 20 |

| Surface roughness after grinding | Ra=0.5 |

Speicfacition of worm grinding wheel

| Size | Dimension/Material | Linear speedm/s) |

| 220*180*90 | 3SG80/100JV | 75 |

| 240*230*110 | 3SG80/100JV | 63 |

| 275*160*160 | 3SG80/100JV | 80 |

| 280*160*115 | 3SG80/100JV | 80 |

| 300*125*160 | 3SG80/100JV | 63 |

| 300*145*160 | 3SG80/100JV | 63 |

| 350*104*160 | 3SG80/100JV | 63 |

| 400*100*203 | 3SG80/100JV | 63 |

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.