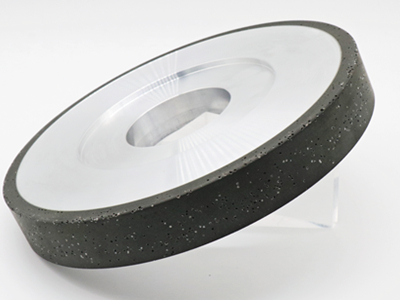

Resin diamond grinding wheel for polyurethane rollers

Large pores resin diamond grinding wheel for PU roller

Polyurethane rollers

Polyurethane rollers are cylindrical components covered with polyurethane. Compared with ordinary rollers, polyurethane rollers have higher mechanical strength, excellent wear resistance, outstanding compression resistance, high resilience, and tear resistance. Polyurethane rollers are used in industries such as papermaking, steel, printing and dyeing, textiles, and grain processing.

Why are polyurethane rubber rollers difficult to process?

Polyurethane rubber rollers are soft and highly elastic, making them prone to generating small debris during the grinding process.

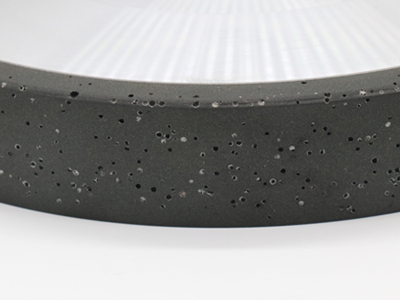

During the grinding polyurethane rubber rollers with fine-grit resin-bonded diamond grinding wheels, can not effectively remove the sticky debris generated during grinding. This leads to debris adhering to the surface of the abrasive grains and filling the gaps between them, causing clogging and damaging the surface accuracy of the rubber roller while also reducing grinding efficiency.

Moresuperhard New formula resin-bonded diamond grinding wheel for polyurethane rollers

The Moresuperhard production team experimented with adding pore-forming agents to the grinding wheel formula, creating large pores in the grinding wheel structure. This improves chip removal efficiency while reducing grinding heat, allowing the grinding wheel to adapt to this special grinding environment.

During trial production, the surface roughness of the rubber roller achieved the expected level briefly during the initial grinding process with the resin-bonded diamond grinding wheel; however, as grinding continued, the chip removal problem of the fine-grained grinding wheel became increasingly prominent, resulting in significant clogging. This led to scratches and adhesion marks on the rubber roller surface, failing to meet the requirements for precision applications.

The clogging problem was subsequently resolved by adjusting the grit size parameters and optimizing the pore structure of the grinding wheel, confirming the critical need to prioritize chip removal performance when using fine-grained grinding wheels in the grinding of polyurethane rubber rollers.

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.