Polishing film for rubber roll/Gravure Roller

Mirror roller: Alumina polishing film

Gravure Roller: Silicon carbide polishing film

Rubber roll: Alumina polishing film

Diamond polishing film:Ceramic corrugated roller, Ceramic Anilox Roller

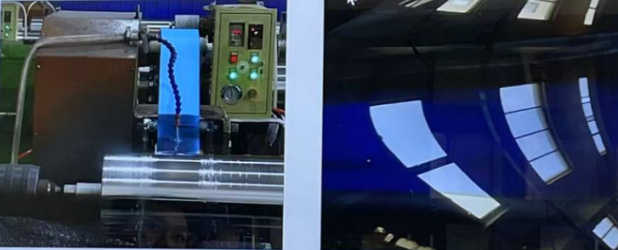

Alumina polishing film for polishing mirror roller

Polishing requirements

* Pressure: 2-6kg

* Surface requirements: Generally, there is no instrument detection in the middle, mainly by naked eye observation. Ra<0.01um, that is, the finish level 14; there are also low requirements of Ra<0.1um;

* Some strict requirements (super mirror roller) are polished with alumina precision grinding belt, and then polished with AO coated products for 3-5 times, and finally polished with 1u wire cloth.

Mirror roller material: steel roller + chrome plating

Mirror roller polishing process: Alumina precision grinding belt EW60-EW30-EW15-EW9. Some have high requirements and may have AO9, AO3, AO1, etc., and finally polish with 1μm flannel

Specifications: 101.6 mm x 46 mm

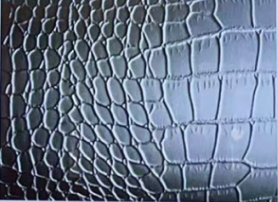

Silicon carbide polishing film for Gravure Roller

Gravure roller polishing is basically similar to that of mirror roller. The product is 101.6 mm x 46 mm, and is mainly made of alumina precision grinding belt products.

Grain size: 30, 40, 50, 60um, generally polished once

Plate making generally refers to gravure roller making, which consists of four layers from the inside to the outside: base steel roller, nickel layer, copper layer and chromium layer.

Processing technology: steel roller size processing – nickel plating – steel plating – engraving – chrome plating – polishing.

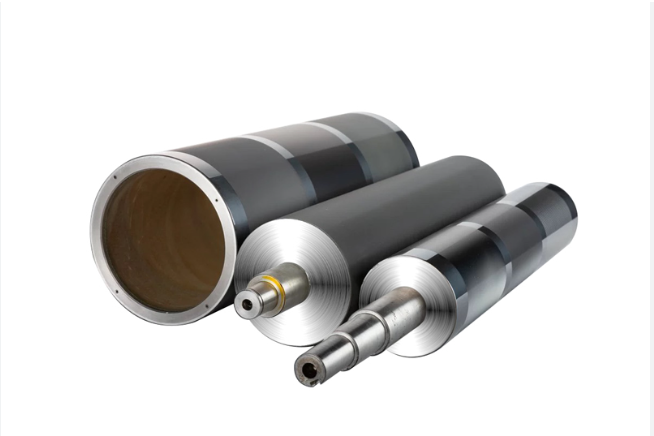

Alumina polishing film for rubber roll

Rubber roller is also a kind of roller. The polishing is basically similar to that of mirror roller. The product is 101.6mmx46m and polished with silicon carbide precision grinding belt.

Grain size 40um, 30um, 15um, 9um

Process: 45 or 40-30-15-9

Roller polishing

Alumina polishing film is used for rollers with lower hardness; silicon carbidepolishing film is used for roller polishing with higher hardness.

Due to market demand, the hardness of rollers is constantly increasing, and silicon carbide polishing film is increasingly used. Generally, the polishing film is used more than 2 times, so the grinding force and life are required to be higher.

Grit: 40μm、30μm、15μm、9μm

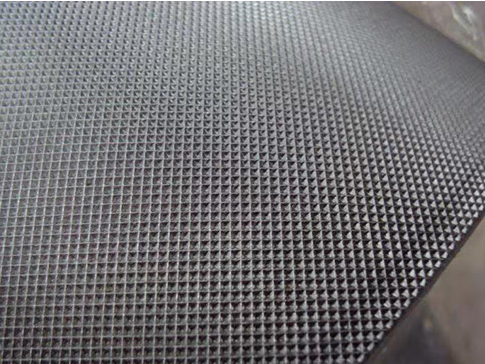

Diamond polishing film for polishing Ceramic corrugated roller/Ceramic Anilox Roller

Tungsten carbide corrugated rollers are generally made of 48CrMoA steel, which is treated by medium frequency annealing or annealing, and its hardness is generally above HRC55.

The hardness of tungsten carbide corrugated rollers is generally above HV1100, which is much higher than that of ordinary corrugated rollers. The average service life of tungsten carbide corrugated rollers in the packaging machinery industry is 30 million meters, which is 3-5 times longer than that of ordinary chrome-plated corrugated rollers. Tungsten carbide rollers have high hardness, good wear resistance, and obvious life advantages, and can maintain high-precision production for a long time.

Chrome-plated rollers

Hardness HRC55-60, suitable for medium and low-speed production with a life of about 8-9 million running meters

Ra15-20 after spraying WC Ra2.5μm after polishing with lapping film Ra1.6μm after polishing with coating

Tungsten carbide rollers

Hardness greater than HV1100, suitable for high-speed production with a life of about 20-50 million running meters

After polishing, the surface roughness achieves Ra2.5μm.

Ceramic Anilox Roller polishing

Ceramic anilox roller

The anilox roller is a special ink transfer roller for flexographic printing machines. Its surface is made with countless ink holes of the same size, shape and depth. It can be used in various types of flexographic printing systems such as label flexographic printing machines, medium and wide flexographic printing machines, and corrugated paper box ink printing slotting machines. According to the different surface coating materials, it can be divided into chrome-plated anilox rollers and laser-engraved ceramic anilox rollers.

Compared with chrome-plated anilox rollers, ceramic anilox rollers have the advantages of good chemical stability, low friction coefficient, and corrosion resistance, and have a wide range of applications.

Ceramic anilox roller production process

Using high-energy plasma thermal spraying processing, a layer of metal oxide CrO; ceramic material is sprayed on the surface of the metal wheel, and then precision grinding and polishing processes are used to make the roller surface ceramic layer reach a mirror effect, and then the high energy of the laser beam is used to vaporize the ceramic layer to complete the engraving of the anilox shape.

Ceramic anilox roller production process

Roller body pre-processing – sandblasting – spraying ceramic powder – polishing – laser engraving – anilox roller

Generally diamond sand-planted grinding belt and diamond polishing belt are used, Ra<0.05.

The thickness of the chrome plating layer is 12-18um, and the thickness of the sprayed ceramic layer is 25-30um.

| Anilox Roller Type | Range of application | Hardness | Life |

| Chrome roller | <400 lines | HRC55-60/HV600-750 | 10 million times – 30 million times |

| Ceramic anilox roller | ≤2000 lines | HV1250 | 50 million times – 100 million times |

| Type of polishing film | Application |

| Alumina precision polishing film | Automobile engine, metal roller, plate making, etc. |

| Siliconcarbide polishing film | Rollers, rubber rollers (papermaking), automobile engines, etc. |

| Diamond polishing film | Tungsten carbide corrugated rollers, ceramic anilox rollers, etc. |

Speciation of electrostatic silicon carbide film belt

| Micron Grade | Color |

| 3 | Gray |

| 5 | Gray |

| 9 | Gray |

| 15 | Gray |

| 30 | Green |

Speciation of electrostatic diamond film belt:

| Micron Grade | Color |

| 0.5 | White |

| 1 | Lavender |

| 3 | Pink |

| 6 | Brown |

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.