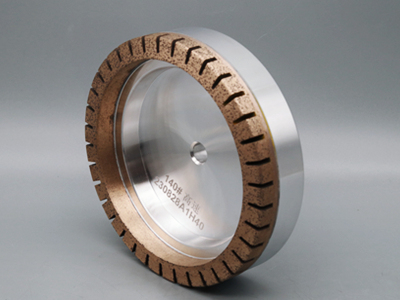

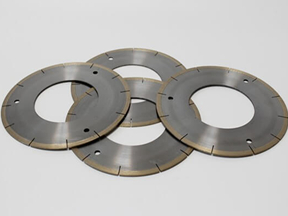

Metal bond segmented diamond cup wheel

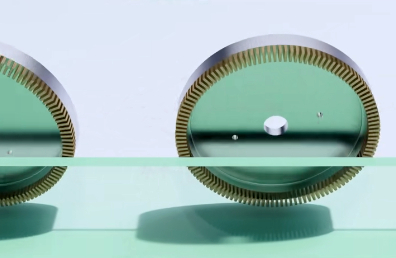

Half and full Segmental cup wheels

Type: metal

For edging machine and double edging machine,straight-line edger, beveling machine

Full Segmented/ Segmented dense teeth/ Outer Segmental/Half Segmened

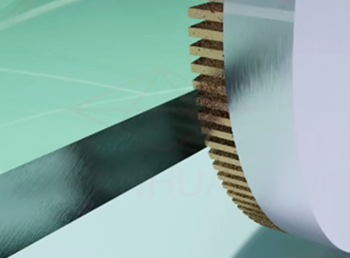

Metal bond segmented diamond cup wheel sintering by high-quality sharp diamond material and scientific sintering process, specially designed and developed adhesives and shapes perfect match of metal bonds, provide excellent removal capabilities at high speeds. The uniform toothed type abrasive layer full heat dissipation during grinding, which can provide space, Enhanced cooling during edging, rapid removal of glass chip, reduce the temperature of the working surface, and protect the glass burns or explosions.

Moresuperhard Metal bond segmented diamond cup wheel consists of slotted shape metal grinding wheels to ensure excellent performance on all types of glass. The shape combined with the adhesive, enables a good flat edge surface finish in order to prepare for the final polishing of all types of glass.

Applicable machine of Metal bond segmented diamond cup wheel:

Metal bond segmented diamond cup wheel for edging machine and double edging machine,straight-line edger, beveling machine, etc…

Moresuperhard can make half and full Segmental cup wheels as follows:

-Full Segmented metal diamond cup wheel

-Segmented dense teeth metal diamond cup wheel

-Outer Segmental metal diamond cup wheel

-Half Segmened metal diamond cup wheel

Difference between half inner teeth and half outer teeth:

Half inner teeth

The teeth of the half inner tooth diamond wheel are in the inner part, when the grinding wheel rotates, the tooth shape will play a transverse cutting role, its transverse cutting force is half or less of the full tooth, the cutting point is after the outer ring enters, under the action of centrifugal force, water will be hidden in the teeth, play a rapid cooling and smooth wear chips away. Prevent the temperature of the cutting surface from overheating and effective cutting surface.

Half outer teeth

When the longitudinal cutting, the cutting point on the external surface, the tooth profile of the half external tooth, each tooth like each tools and the space in the tooth will take the chip away.

So, the half inner tooth is suitable for transverse cutting, the half outer tooth is suitable for longitudinal cutting, the half inner tooth is suitable for straight edge machine or double side machine, and the half outer tooth is suitable for bevel machine or shaped bevel machine.

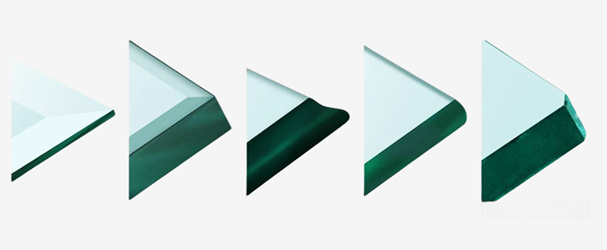

Application of metal diamond cup wheel:

Metal bond segmented diamond cup wheel is suitable for rough grinding of similar glass plates such as architectural glass and furniture glass. Use on straight/double edge grinding machine, bevel edge machine, etc.

Advantages of metal diamond cup wheel:

1. High speed, flexible.

2. Optimized edge surface processing.

3. Long service life.

4. Glass edge does not break, no smooth surface texture after processing.

Half and full Segmental cup wheels both have resin bond and metal bond, Which have external sharp segments for optimal glass edging. Selecting the suitable wheel depends on processing internal or external edging glass.

Technical parameters:

| Speed | 4800r/min |

| Feed rate | 0.5-1mm |

| Glass Bevel width | 0.5-3.5mm |

| Location | Position 2 |

| Machine | For double-sided machine; straight beveling machine, special-shaped bevel edge machine. |

| Full Segmented | ||||

|

D(mm) | H(mm) | Diamond Layer(mm) | Grit |

| 150 | 12,22,25,50 | 15×10 | 80,100,120,140 | |

| 175 | 12,50 | 15×10 | 80,100,120,140 | |

| For edging machine and double edging machine as position 1.

Good grinding effect for Laminated Glass Processing. |

||||

| Segmented dense teeth | ||||

|

D(mm) | H(mm) | Diamond Layer(mm) | Grit |

| 150 | 12,22,50 | 15×10 | 100,120,140 | |

| 175 | 12,22,50 | 15×10 | 100,120,140 | |

| With high Feeding Speed. (8M/min~18M/min)on High Speed Duouble Edger. | ||||

| Outer Segmental | ||||

|

D(mm) | H(mm) | Diamond Layer(mm) | Grit |

| 150 | 12,22,25,50 | 13×10 | 100,140,180 | |

| 175 | 12,50 | 13×10 | 100,140,180 | |

| 1.Used as position 2 for straight-line edger and double edger

2. Specical for laminated glass as position 1& 2 position |

||||

| Half Segmened | ||||

|

D(mm) | H(mm) | Diamond Layer(mm) | Grit |

| 150 | 12,22 | 7×12 | 80.100.120.140 | |

| Used for beveling machine | ||||

Related Products

-

Metal Bond Diamond Cutting disc for Quartz Glass

Metal Bond Diamond Cutting disc for Quartz GlassMetal Bond Diamond Cutting disc for Quartz Glass

-

Diamond Pencil Edge Grinding Wheel for Auto Glass

Diamond Pencil Edge Grinding Wheel for Auto GlassDiamond Pencil Edge Grinding Wheel for Auto Glass

-

Metal Diamond Cup Grinding Wheel for Architectural And Furniture Glass

Metal Diamond Cup Grinding Wheel for Architectural And Furniture GlassMetal Diamond Cup Grinding Wheel for Architectural And Furniture Glass

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.