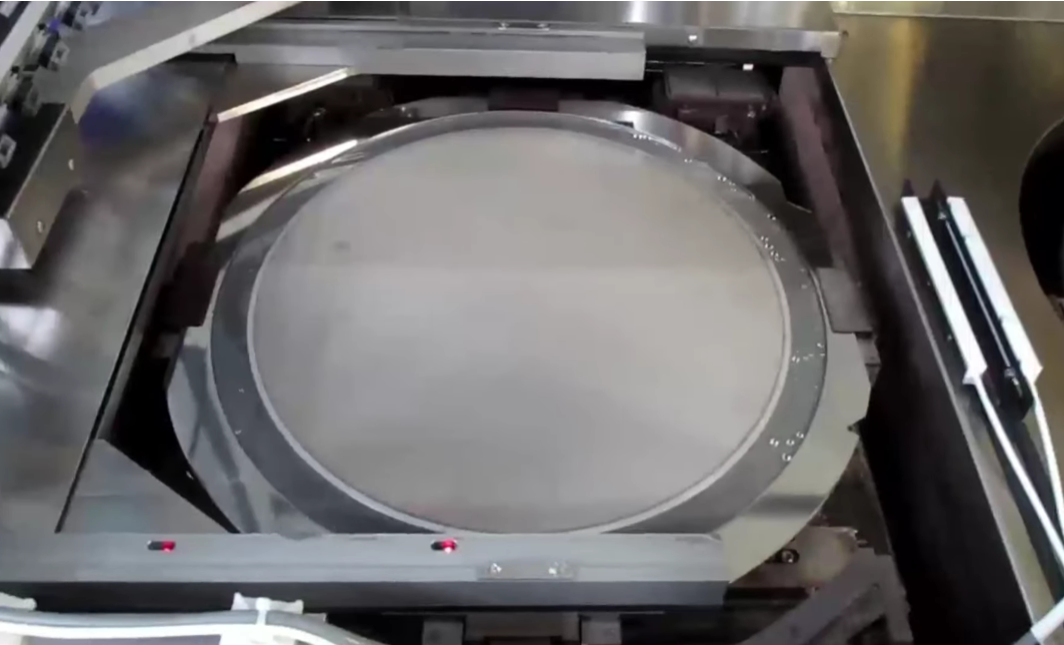

Porous ceramic vacuum chuck

Size range: 4″–12″

Micropore size: 5μm-100μm

Shape: Circular, Square, Rectangular

Flatness: 3μm, 5μm, 10μm

Suitable devices: Wafer grinder, dicing machine cleaning machine, etc

Porous ceramic vacuum chucks are made of porous ceramic materials with uniform pore size distribution and interconnected pores. After grinding, the surface is smooth and delicate with good flatness. They are widely used in the manufacturing of semiconductor wafers such as silicon, sapphire, and gallium arsenide.

Working Principle of Porous ceramic vacuum chuck

Porous Ceramic Vacuum Chuck is a bearing platform that uses the principle of vacuum adsorption to fix the workpiece. The part of the vacuum chuck that transmits vacuum is a porous ceramic plate. The porous ceramic plate is assembled in the countersunk hole of the base, and its periphery is bonded and sealed with the base. The base is made of precision ceramic or metal materials. By combining the metal or ceramic base and the special porous ceramic, and the design of the internal precision airway, the workpiece can be smoothly and firmly adsorbed on the vacuum chuck when negative pressure is applied.

Because the holes of porous ceramics are very fine, when the surface of the workpiece is attached to the vacuum chuck, the surface will not be scratched or dented due to negative pressure.

Ceramic vacuum chuck is a tool for clamping and carrying in the production of semiconductor wafers. Ceramic vacuum chuck is suitable for thinning, cutting, grinding, cleaning and processing processes in semiconductor wafer manufacturing, and has achieved extremely high processing quality of semiconductor wafers in practical applications.

Different types of Vacuum Chuck Table:

(1)Thinning Chucks

(2)Dicing Chucks

(3)Cleaning Chucks

(4)Transportation Chucks

(5)Printing Chucks

(6)Custom is available

Characteristics of Porous ceramic vacuum chuck

1. High flatness and parallelism

2. Compact and uniform microstructure with high strength

3. Good permeability and uniform adsorption affinity

4. Long life

5. Dressing easily

| Shape | Size |

| Round | 4″, 5″,6″,8,”9”, 12″ |

| Squre | 4″,5″,6″, 8″, 12″, 20″ |

| Rectangle | 2*4, 4*6, 6*8, 6*12 |

| Optional material for base and frame | Aluminum Alloy /Stainless Steel/ Ceramics. |

| Porosity | 30-40% |

| Permeability uniformity | 10 x 10 mm pressure difference(±3 Kpa) |

| Can design and make nonstandard chuck tables according to customers’ requirement | |

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.