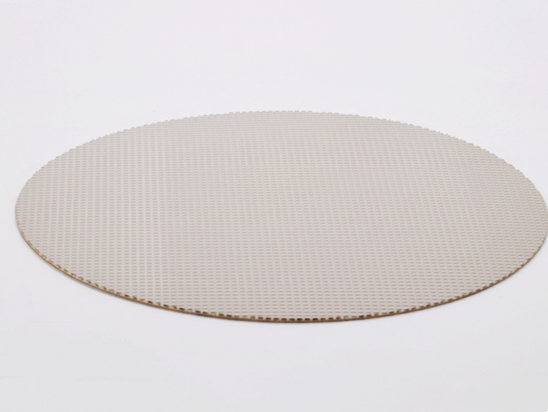

Polyurethane polishing pads for polishing sapphire

Polishing pad type: MSH-57, MSH-87

Workpiece: Sapphire, Steel

Size: D762xT1.27mm

Sapphire polishing

Sapphire is widely used in high-end applications such as optical lenses, LED substrates, watch crystals, and semiconductor wafers due to its superior hardness and transparency.

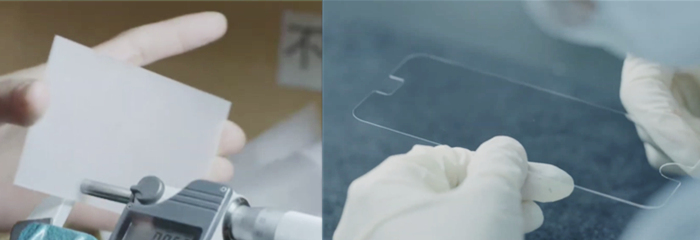

Sapphire needs to go through multiple processes before being made into a finished product, the most common of which are cutting, grinding and polishing. Surface processing is a crucial procedure. To meet the required surface roughness, smoothness and flatness of the workpiece, polishing treatment is necessary.

Achieving a flawless surface finish on sapphire requires precision polishing tools, and the PU (Polyurethane) polishing pad is the ideal chioce for both lapping and final polishing.

PU Polishing Pad for Sapphire Lapping and Polishing

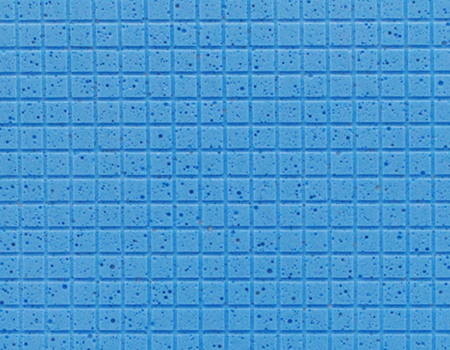

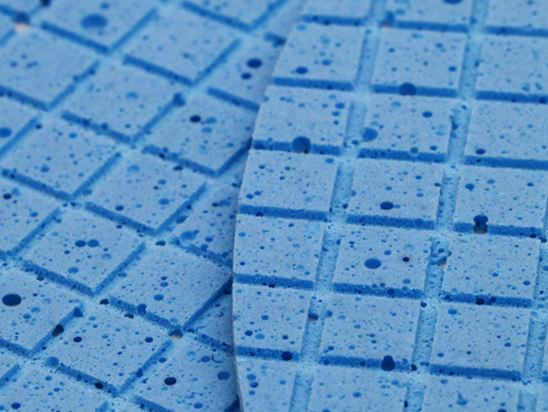

PU (Polyurethane) polishing pad is a specially formulated pad designed for precision polishing of sapphire. It is made of polyurethane material, often filled with abrasive fillers (such as silica or alumina) to provide a balanced cutting action and surface smoothness.

Sapphire is highly hard and wear-resistant, and the requirements for polishing pads are also extremely high. MORESUPERHARD can customize specific hardness to polish sapphire.

CMP polishing for polishing sapphire

CMP polishing is a process where a polishing pad and polishing liquid work together to remove the microscopic unevenness on the surface of sapphire through a combination of chemical reactions and mechanical friction, achieving extremely high surface flatness and smoothness, etc. Polyurethane polishing pads have excellent elasticity and wear resistance, and can maintain relatively stable performance under continuous abrasive action.

Application of PU polishing pad

* LCD, Glass, Glass Disk, Precision Optics

* Fiber Optics, Quartz, Sapphire, Silicon

* Stainless Steel, Alumina, Silicon Carbide, Ophthalmics

Key properties:

* Uniform Microstructure: Ensures consistent contact between pad and workpiece.

* Controlled Hardness: Prevents scratches while maintaining stable removal rates.

* High Durability: Resistant to wear and chemicals used in polishing slurries.

* Excellent Planarity: Helps achieve high flatness and mirror-like finishes on sapphire wafers and substrates.

* These pads are typically used with diamond slurry or colloidal silica slurry for final polishing steps, ensuring low surface roughness (Ra < 5 nm).

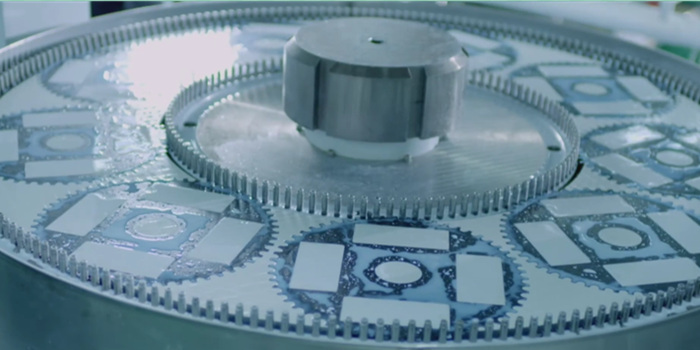

Machines Compatible with PU Polishing Pads

* Double-Side Lapping and Polishing Machines (for wafer-level polishing, e.g., Logitech, Engis, SpeedFam, and other industry machines).

* Single-Side Polishing Machines (for precision optical lenses and watch crystals).

* CNC Precision Polishers (for custom sapphire components with complex shapes).

* High-Throughput Wafer Polishers (semiconductor and LED industry production lines).

| Pad Diameter (mm) | Pad Thickness (mm) | Application |

| 150 | 1.0 – 2.0 | Small wafer polishing, R&D labs |

| 200 | 1.0 – 2.5 | Optical components, lenses |

| 300 | 1.0 – 3.0 | Sapphire LED substrates |

| 350 | 1.5 – 3.0 | Semiconductor wafers |

| 400 | 2.0 – 3.0 | High-volume sapphire wafer polishing |

| 450 | 2.0 – 3.5 | Large substrate/lens polishing |

| Custom sizes | Up to 600 mm | Tailored to the customer’s machine |

Related Products

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.