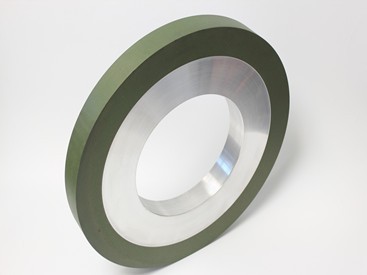

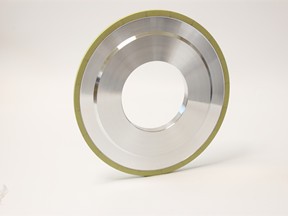

OD Cylindrical Peel Grinding Wheel

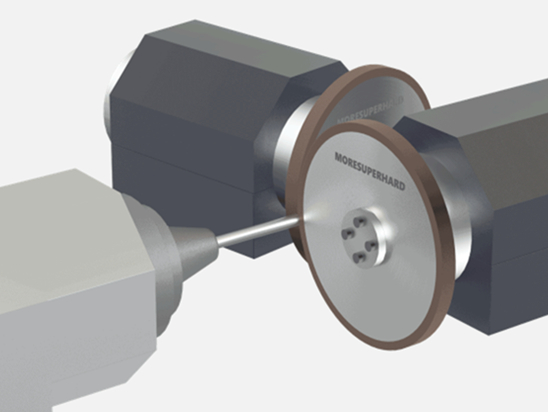

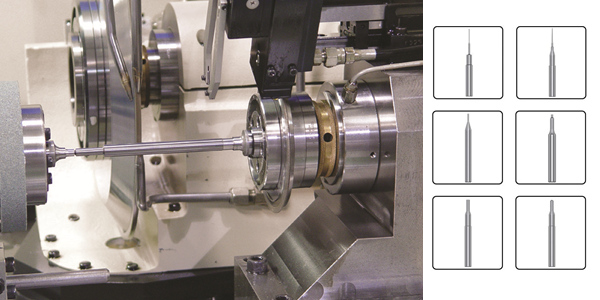

Pinch and Peel grinding on CNC tool grinder

► Bond: Vitrified CBN wheel , electroplated plated CBN wheel

► Application: external cylindrical grinding of milling cutters, drills and wiretapping, grooves, flats, threads and chamfers, etc

OD Peel Cylindrical Grinding

Peel grinding operations of a variety of diameters, grooves, thrust faces and forms using one set-up. It is suitable for external cylindrical grinding of milling cutters, drills and wire tapping, grooves, flats, threads and chamfers, etc

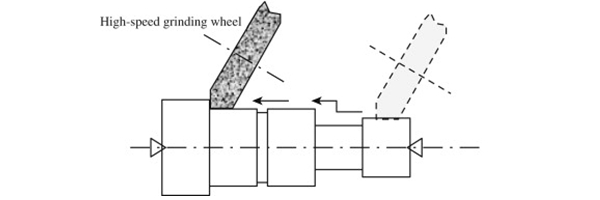

What is Peel grinding?

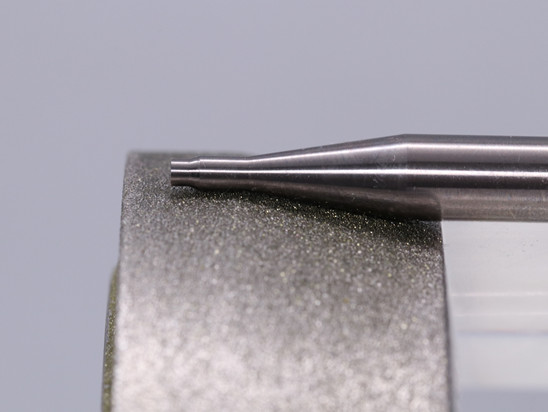

Peel grinding belongs to cylindrical grinding, refers to high speed grinding of cylindrical and non – cylindrical shaft workpieces. When grinding a non-cylindrical workpiece, the grinding wheel rotates at a high speed (usually 90-150 m/s) and moves axially at a certain grinding cut depth to achieve axial feed (>100mm/min) and peel the material from the workpiece surface. Because the grinding wheel is very thin, the workpiece speed in the grinding process needs to be large enough to avoid the occurrence of spiral lines.

The precision of cylindrical peel grinding is high, which is suitable for hard materials that can not be processed by traditional processing. peel grinding is a kind of grinding method similar to traditional turning, which is the main competitor of hard turning. It has good flexibility and high grinding efficiency. Peel grinding ensures polished surface finish and unmatched performance to micron level accuracy.

Application of peel grinding

– For high precision CNC cylindrical peel grinding machine, widely used for profile cylindrical peel grionding former working procedure of milling cutter, drill bit, tapping, non – standard carbide rotary tools.

– Automotive industry: Transmission, drive shaft, gear grinding, etc.

– The two main markets for peel (and squeeze) grinding are grinding parts and cutting tool blanks. Suitable for grinding precision punch, micro pin, die parts and other products.

– It is not only suitable for the preparation of cylindrical blanks, but also for non-circular applications. Especially suitable for flat, threaded and non-circular punch applications.

Features of Peel Grinding

— High-precision, high-efficiency

— Center-going, step-difference forming external cylindrical grinding

— The punches and needles are rough and finely ground at one time, and the finish is high

— With less frequent dressing in the case of vitrified CBN wheels or without dressing in the case of plated CBN wheels

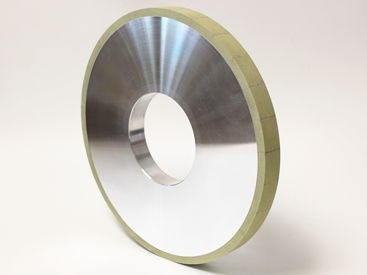

Rough Grinding: Vitrified bond grinding wheel (has better efficiency than resin grinding wheels) or electroplated grinding wheels

Finish Grinding: Metal grinding wheel

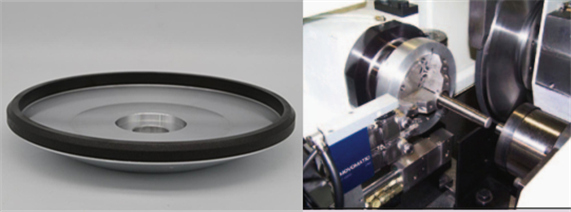

Case 1 peel grinding Tapered Bolt with vitrified CBN grinding wheel

| Application for Tapered Bolt (Inconel 718) | |

| Configuration | Straight wheel, CBN (vitrified) |

| Process | High-speed “peel” grind: multi-pass. Grinds head-end shoulder, fillet radius, tapered body diameter, transition angle, thread-roll diameter and nose-end angle |

| Attributes | Diameter tolerance +/- .0002” |

| Surface finish | Ra16 |

| Dressing | Rotary diamond dresser |

| Peel Rough Grinding | ||

| Size | Grinding Wheel | 3v1 250D * 20T * 31.75H * 6X |

| Workpiece | Φ6.0mm | |

| CNC Machine | Rollomatic | |

| Speed of grinding wheel | 70 m/s | |

| Feed rate | 1.25mm | |

| Feed speed | 18mm /min | |

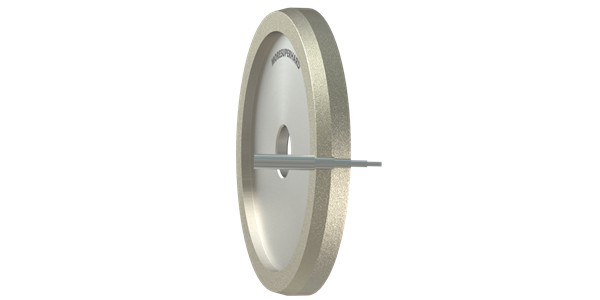

Case 2 12bt9 grinding wheel for peel fine grinding

| Peel Fine Grinding | ||

| Size | Grinding Wheel | 12BT9 150D * 25T * 31.75H * 6X |

| Workpiece | Φ6.0mm | |

| CNC Machine | Rollomatic | |

| Speed of grinding wheel | 42 m/s | |

| Feed rate | 0.02mm | |

| Feed speed | 12mm /min | |

Related Products

-

Diamond Cylindrical Wheel for Precision Ceramic Grinding

Diamond Cylindrical Wheel for Precision Ceramic Grinding

-

Diamond Cylindrical Grinding Wheel for HVOF Thermal Spraying Coatings

Diamond Cylindrical Grinding Wheel for HVOF Thermal Spraying Coatings

-

Diamond Wheels for Silicon Ingot, Cylindrical Grinding/ OD Grinding

Diamond Wheels for Silicon Ingot, Cylindrical Grinding/ OD Grinding

-

Vitrified diamond Cylindrical Grinding wheel for PDC Cutter Chamfer grinding

Vitrified diamond Cylindrical Grinding wheel for PDC Cutter Chamfer grinding

-

peel and pinch grinding wheel for external cylindrical grinding of milling cutters, drills and wiretapping, grooves, flats, threads and chamfers, etc

OD Cylindrical Peel Grinding Wheel

-

Cylindrical vitrified diamond grinding wheel is used for PCD tools grinding with large cylindrical grinding machines.

Cylindrical Diamond Wheel for PCD Reamer Grinding

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.