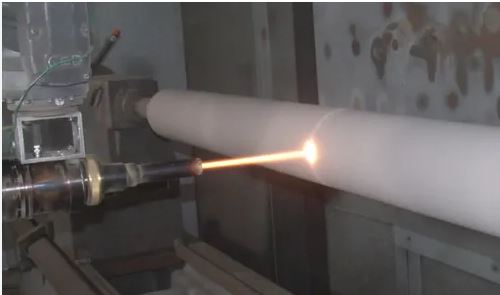

Case of electroplated diamond abrasive belts for processing ceramic coating and cast iron rollers

What are the characteristics of ceramics thermal spray coating?

The life of the roll mainly depends on the intrinsic performance and working force of the roll. The intrinsic performance includes strength and hardness. To make the roll have sufficient strength, we mainly consider the roll material; hardness usually refers to the hardness of the working surface of the roll, which determines the wear resistance of the roll and, to a certain extent, also determines the service life of the roll. Through reasonable material selection And the heat treatment method can meet the hardness requirements of the roll.

Rolls must be able to withstand corrosion under high temperature reducing conditions and withstand multiple thermal cycles without failure. The surface is wear-resistant and can maintain the required minimum surface roughness to avoid sliding or extrusion of the steel plate on the surface of the roller. Due to the improvement of production efficiency and the increase of strip running speed, the control of strip movement is becoming more and more important. Finally, the roller must be able to resist surface agglomeration due to the adherent accumulation of foreign particles/oxides. When the roll surface is smooth, the average load on the roll surface is relatively low, but when the local load on the roll surface increases due to the formation of adherents, dents and scratches appear on the surface of the heat-softened steel strip. These defects later appear are difficult to eliminate during the smoothing process. Defects such as grooves and wear marks on the surface of the roll will promote the formation of adherents and affect the surface quality of the steel plate.

In a working environment of 1100°C, oxide ceramics or boride cermets are generally used. Typical materials include MCrAlY+Al2O3, NiCrAlY+ 50 % ZrB/CrB/TiB, CoCrAlY+CrB2/Y2O3. The oxidation of high-temperature alloys creates a thin oxide layer, which increases the coating’s resistance to build-up formation.

Ceramic coating materials mainly include oxides, borides, silicides, and carbide ceramics. Their melting points are very high, mostly above 2000°C, and they have good chemical stability.

Among them, oxides are widely used. They have excellent chemical stability in oxidizing atmospheres, high melting points, and good wear resistance and electrical insulation properties. Therefore, it is mostly used as a high-temperature-resistant, heat-insulating, insulating, wear-resistant, and corrosion-resistant coating. The most commonly used oxide ceramics include alumina, magnesium oxide, titanium oxide, chromium oxide, zirconium oxide, etc.

Characteristics of electroplated diamond abrasive belt:

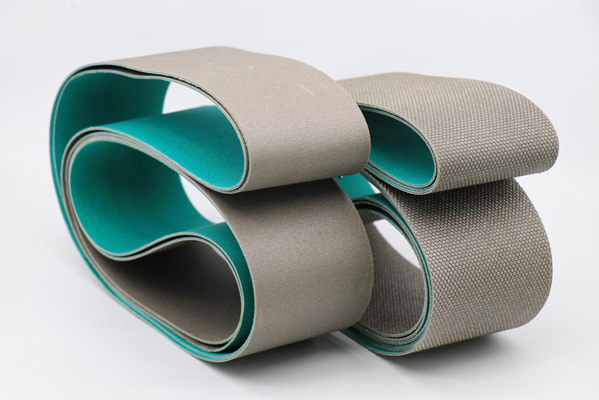

The electroplated diamond abrasive belt is mainly composed of diamond abrasive grains, coating metal (nickel) and base material. The diamond abrasive grains are attached to the base material through electroplating of nickel to form a diamond abrasive grinding layer wrapped with coated metal. The nickel plating layer Diamond abrasive grains are firmly fixed on the substrate and have the advantages of high hardness, strength, and long belt life.

Electroplated diamond abrasive belt grinding is a composite processing technology that uses flexible grinding tools to carry out grinding, grinding and polishing. It has a “cold” effect and is especially suitable for hard and brittle non-metallic materials and non-ferrous metals.

CBN abrasive belts can be used for grinding and polishing difficult-to-machine materials containing iron group elements such as steel and ferroalloys, especially high-hardness steels such as high-carbon steel, alloy steel, and quenched steel.

Recently, Moresuperhard had one customer, who wanted polishing ceramic and cust iron roll, suggested electroplated diamond sanding belt for him. Let’s see the process together:

Feedback from our customers:

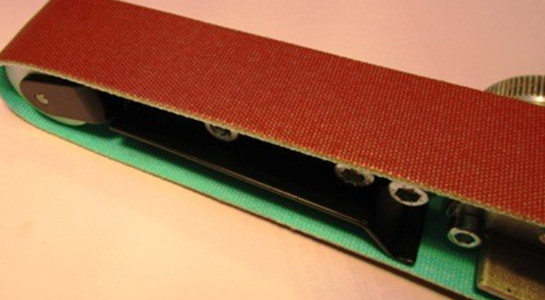

Regarding complaint of diamond belt. Customer said they used to grind roll only 3 rolls then it cracked off from the backing.

The roll material is ceramic and cast iron. Hardness 500-1000 HV.

Parameter using is roll speed 20-25 m/min, travel speed 400-700 mm, feed rate 0.01-0.05 mm

Specifications of electroplated diamond sanding belt:

| Abrasive | Electroplated diamond sanding belt | |

| Size of diamond sanding belt | Width | 100m |

| Length | 2400mm | |

| Grit of diamond sanding belt | 100# | |

Solutions:

No problem just compensate them with new one. No matter if the life time short. Just one time compensate I had promised customer to given replacement for free of charge.

Moresuperhard will continue to follow up on customer usage and look forward to our subsequent updates.