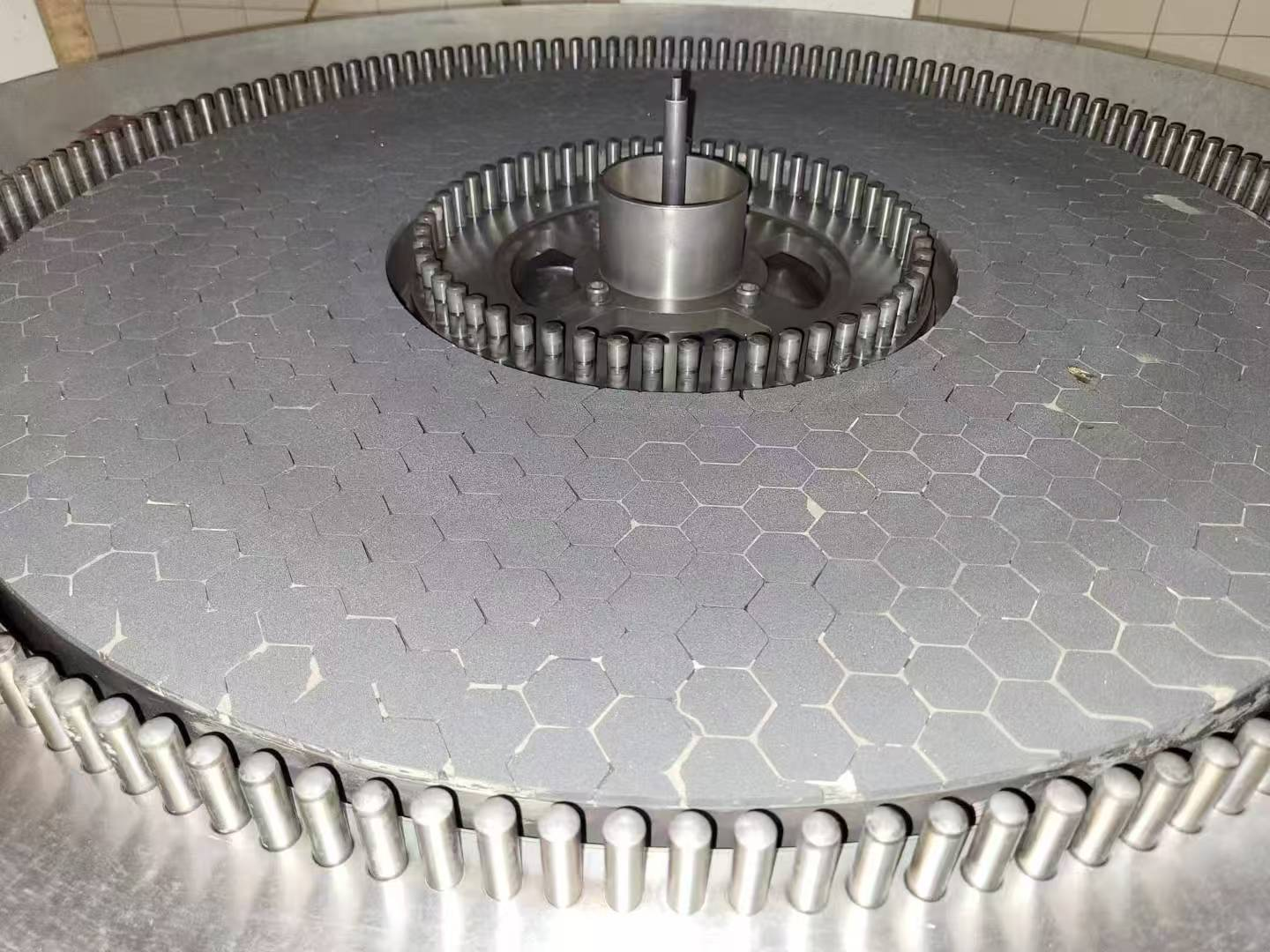

Case of Vitrified CBN Double Disc Grinding Wheel for Lapping Hydraulic Valve Plate

In the field of precision engineering, hydraulic valve plates play a crucial role in ensuring the proper functioning of hydraulic systems. These plates are integral components in hydraulic valves, providing regulation and control for the flow of fluids under pressure. Given their importance, the grinding and lapping of hydraulic valve plates must be performed with high precision to guarantee the proper functionality of the entire hydraulic system.

Vitrified CBN double disc grinding wheels have proven to be one of the most effective tools for grinding and lapping hydraulic valve plates. This article will delve into the nature of hydraulic valve plates, their applications, the grinding process, and the advantages of using vitrified CBN double disc grinding wheels for hydraulic valve plate lapping.

What is a Hydraulic Valve Plate?

A hydraulic valve plate is a component of a hydraulic valve used to control the flow of fluid in hydraulic systems. It consists of a metal plate with precision machined openings that act as flow control passages for hydraulic fluid. Hydraulic valve plates are typically made of high-strength steel or cast iron to withstand the pressure exerted by the fluid while ensuring the system’s optimal performance.

Key Features of Hydraulic Valve Plates:

-

Precision Machining: The hydraulic valve plate features micrometer-level precision in the design and machining of the flow passages. The accuracy of these openings is essential to maintaining fluid flow control and pressure regulation.

-

High Durability: Valve plates are built to handle high-pressure environments, making them an essential component in hydraulic systems used in industrial machinery, construction equipment, and automotive applications.

-

High Tolerance: The flatness, parallelism, and surface finish of the hydraulic valve plate are critical for the proper functioning of the hydraulic valve. Even slight deviations in these aspects can cause issues such as leakage, poor flow control, and system failure.

Common Materials Used:

-

High-strength Steel: Steel is commonly used for valve plates because of its strength, wear resistance, and ability to withstand the high pressure generated in hydraulic systems.

-

Cast Iron: Some valve plates are made from cast iron, which offers durability and is often chosen for its lower cost compared to steel.

- Copper Alloys: In certain cases, copper alloys are used for their corrosion resistance, especially in systems that involve corrosive fluids.

Application of Hydraulic Valve Plates

Hydraulic valve plates are essential components in hydraulic systems, found in a wide range of industries. Their primary function is to regulate the flow of hydraulic fluid within a hydraulic valve, which controls the direction, pressure, and volume of fluid in the system.

Industries and Applications:

-

Automotive Industry:

-

Hydraulic valve plates are used in automotive transmissions, power steering systems, and braking systems. They ensure that fluid is directed to the correct components under the right pressure for smooth and safe operation.

-

-

Construction and Mining:

-

In heavy machinery, such as excavators, loaders, and pumps, hydraulic valve plates regulate the fluid flow for efficient power transmission, offering superior control and performance under tough working conditions.

-

-

Aerospace and Aviation:

-

Hydraulic systems in aircraft rely on high-performance valve plates to maintain precise fluid flow control, ensuring the safe operation of flight control systems, landing gear, and hydraulic braking systems.

-

-

Industrial Manufacturing:

-

Hydraulic valve plates are used in hydraulic presses and machining tools, where precision in fluid flow is critical for consistent, high-quality output.

-

-

Oil and Gas:

-

In the oil and gas sector, hydraulic systems require precise regulation of fluids for the operation of drills, pumps, and safety systems.

-

Given the critical role of hydraulic valve plates in various industrial systems, their precision manufacturing and maintenance are vital for the overall efficiency and safety of these systems.

How to Grind Hydraulic Valve Plates?

Grinding hydraulic valve plates requires careful attention to their flatness, parallelism, and surface finish. Even minor deviations from the correct geometry can compromise the functioning of the valve, causing issues such as leakage or poor fluid flow regulation.

1. Preparing the Valve Plate

-

Inspection: Before grinding, inspect the hydraulic valve plate for any signs of damage, wear, or deviations from the required specifications. This includes measuring the flatness, thickness, and the quality of the flow passages.

-

Mounting: The valve plate should be securely mounted on the grinding machine to ensure stability and accuracy during the grinding process.

2. Selecting the Grinding Wheel

-

Grinding Wheel Selection: The vitrified CBN grinding wheel is the ideal choice for grinding hard materials like steel and cast iron, which are commonly used for hydraulic valve plates. CBN (Cubic Boron Nitride) offers superior hardness, allowing for precise and efficient grinding without excessive wear on the wheel.

-

Grit Size: Coarse grit is typically used for rough grinding, while finer grit is used for finishing to achieve the desired surface quality.

3. Grinding Process

-

Rough Grinding: Start with rough grinding to remove material and shape the hydraulic valve plate. The vitrified CBN wheel will efficiently remove material without causing excessive heat buildup or damage to the plate.

-

Fine Grinding: After rough grinding, switch to a finer grinding wheel to improve the surface finish and achieve the desired geometry. The grinding process should be carried out in multiple passes to ensure an even cut and reduce the risk of overheating or material distortion.

-

Lapping: After grinding, lapping is often used to achieve the desired surface finish. Lapping is a fine grinding process that removes minute surface imperfections and improves the flatness of the valve plate.

4. Cooling and Lubrication

-

During the grinding process, use a coolant to dissipate heat and prevent the formation of cracks or distortion. The coolant also helps to prolong the life of the grinding wheel and ensures the grinding process is carried out efficiently.

5. Final Inspection

-

Once grinding and lapping are completed, perform a final inspection to ensure that the valve plate meets the required specifications. This includes measuring flatness, parallelism, and the quality of the surface finish.

Double Disc Grinding of Hydraulic Valve Plates

Double disc grinding is a high-precision method used to grind both sides of a workpiece simultaneously. This process offers several advantages when it comes to grinding hydraulic valve plates, as it ensures uniform thickness, flatness, and parallelism across both sides of the plate.

Advantages of Double Disc Grinding:

-

High Precision: Double disc grinding ensures that both surfaces of the hydraulic valve plate are ground simultaneously, ensuring that they are parallel and flat to extremely tight tolerances.

-

Increased Efficiency: Grinding both sides at once significantly reduces the time required for processing, making it ideal for high-volume production.

-

Uniform Surface Finish: This process provides a consistent surface finish across both sides of the valve plate, improving the overall quality of the final product.

Advantages of Vitrified CBN Double Disc Grinding Wheel for Hydraulic Valve Plate

The vitrified CBN double disc grinding wheel is one of the most effective tools for grinding and lapping hydraulic valve plates due to its unique properties. Here are the key advantages:

1. Superior Hardness

-

CBN (Cubic Boron Nitride) is one of the hardest materials, second only to diamond. This makes it ideal for grinding hard materials like steel, cast iron, and other alloys commonly used in hydraulic valve plates. The hardness of CBN ensures that the grinding wheel remains sharp for longer periods, reducing wear and increasing efficiency.

2. High Precision and Consistency

-

Vitrified CBN grinding wheels offer excellent form retention and precision. This is critical when grinding hydraulic valve plates, where even small deviations in flatness, parallelism, or surface finish can result in malfunctioning hydraulic systems. The grinding process is highly controlled, ensuring that the final product meets exact specifications.

3. Reduced Heat Generation

-

One of the key benefits of vitrified bond grinding wheels is their ability to dissipate heat effectively. This reduces the risk of thermal damage to the hydraulic valve plate, which could cause distortion or cracking. Proper heat management is crucial when grinding high-performance materials like those used in hydraulic valve plates.

4. Longer Tool Life

-

Vitrified CBN grinding wheels have a longer lifespan compared to traditional abrasive wheels. The durability of these wheels allows them to maintain their grinding performance over extended periods, reducing the frequency of wheel replacements and maintenance costs.

5. Improved Surface Finish

-

The high grinding efficiency and smooth cutting action of CBN grinding wheels result in superior surface finishes. This is particularly important for hydraulic valve plates, as a smooth, polished finish is necessary to ensure optimal fluid flow and prevent leakage.

6. Increased Productivity

-

-

Double disc grinding with vitrified CBN wheels allows for high-speed material removal while maintaining precision. This leads to increased productivity and reduced cycle times, which is essential in high-volume manufacturing environments.

-

Customer cases

| Lapping disc | Vitrified CBN double disc grinding wheel | Diameter | 700mm |

| Grit | 200/230# | ||

| Grinding machine | Stähli DLM 705 double face grinding machine | ||

—EDITOR: Doris Hu, Alan Wang

–POST: Doris Hu