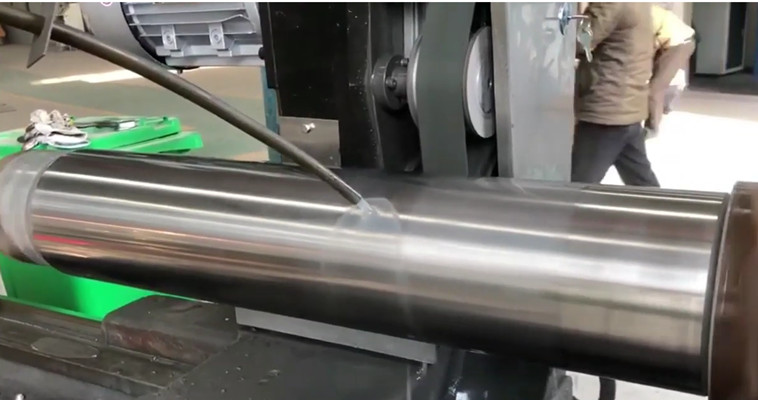

Case of resin diamond sanding belt for polishing tungsten carbide coating

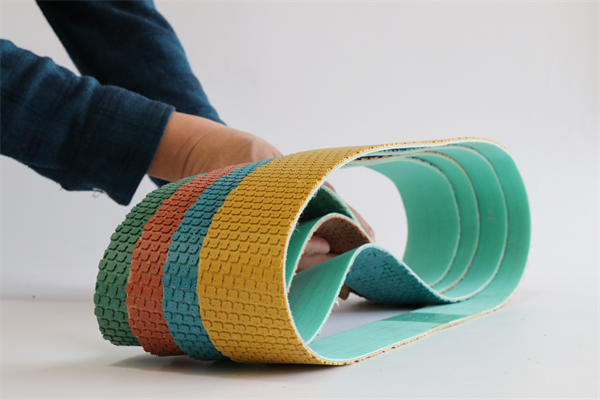

The abrasive belt is a coated abrasive, which is a kind of abrasive made by bonding the abrasive to the bendable substrate with a binder. Because of its safety and processing efficiency, the abrasive belt is a fixed abrasive. The grinding wheel has high grinding speed. At the same time, it is flexible grinding, which can easily fit the surface shape of the workpiece, has small steel impact, low heat generation, and convenient replacement. It has been used more and more.

Resin abrasive belts use resin as a binder, and also have the dual advantages of softness of traditional coated abrasives and high hardness of diamond. However, during the grinding process, heat accumulates next to the diamond. If it cannot be exported or discharged immediately, the temperature here will rise immediately, causing the binder to melt, and the diamond will fall off before it can fully function, and the service life will be short. Therefore, the diamond resin abrasive belt must be cooled with water for grinding.

What are the characteristics of abrasive belt grinding?

1 Strong and efficient, long life

2 High grinding production efficiency

3 good grinding quality

4 Wide range of applications

5 Low production cost and good economic benefits

6 Very good flexibility and flexibility, adapt to various shapes of parts

Resin diamond sanding belt moderate in hardness and softness, and is used for grinding and polishing glass, stone, ceramics, hard alloy, thermal spraying surface, metal surface oxide layer, etc. It has the advantages of excellent performance and high polishing efficiency.

In general, resin diamond abrasive belts are used for polishing tungsten carbide. The choice of abrasive belt size is related to the smoothness of the polished object and the required removal rate.

Common particle sizes of abrasive belts are 40#, 60#, 120#, 400#, 800#, 1500# and 3000#. , and its corresponding smoothness (Ra).

| Grit | Surface Roughness(Ra) |

| 40 | 2.50 |

| 60 | 2.10 |

| 120 | 1.60 |

| 200 | 0.60 |

| 400 | 0.20 |

| 800 | 0.10 |

| 1500 | 0.05 |

| 3000 | 0.02 |