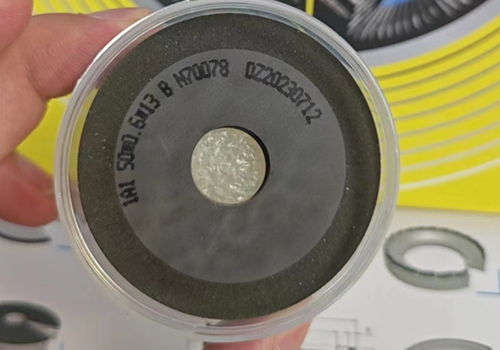

Case of resin diamond cutting disc for spring collet

What is a spring collet?

Spring collets is a cylindrical fixture used to install a drill bit or a milling cutter on a milling machine. Spring collets is a fixing device used to fix and strengthen parts that need to be modified.

The collet fits into the lock nut, and the lock nut with the collet mounted is lightly threaded onto the tool holder, adapter or spindle. Relying on the elasticity of the spring steel for tightening, it is easy to loosen the clamp, and is mostly used for clamping cutting tools with light and medium loads. It is often used for clamping cutting tools such as end mills, drills, taps, reamers, and center drills. Change the clamping range by changing different collets.

When clamping, clean the threaded part, positioning surface and cone surface of the spring collet and lock nut. During the installation process of the collet and the lock nut, the collet and the lock nut must be inclined at a certain angle, and then put into the locking groove of the lock nut. Do not use an extended strong wrench to tighten the torque too much to prevent damage to the tool and fixture.

Moresuperhard resin diamond cutting disc for the collet has the characteristics of high sharpness, high precision, small burr and long life.

Case of resin diamond cutting disc for spring collet

| Workpiece | Spring collet |

| Material | Die steel |

| Requirements of customer | Grooving on the side, requiring high efficiency, long life, and avoiding burns |

| Testing result | For the first time, the resin diamond cutting disc was broken as a whole (the reason is that the speed is too low, 800 rpm, it is recommended to increase the speed) |

| The second time the workpiece is burned (the reason is that the speed is 8000 rpm, the speed is too low, let it increase the speed and try again, and then cool down and balance.) | |

| The third time the resin diamond cutting disc cracked and collapsed (the binder formula is not good enough for high temperature treatment, and some binder areas are prone to deformation due to high temperature, resulting in cracking, and the high temperature resistance formula needs to be improved) |

Although the third test still failed, Moresuperhard will continue to make adjustments, formulate a suitable formula, and continue to provide after-sales services to this customer. We will continue to send him new resin diamond cutting discs for free, looking forward to Moresupehard’s new formula cutting Sheet cutting collet final effect bar.

—EDITOR: Doris Hu, Shang feng, Niu

—POST: Doris