Case of Resin Diamond Cutting Disc for Cutting C799 Al2O3 Ceramic Pipe

In the world of advanced ceramic materials, C799 Al2O3 (Aluminum Oxide) ceramic pipes are widely utilized for their excellent mechanical strength, chemical resistance, and high thermal stability. These attributes make them suitable for a range of demanding applications, including in the chemical industry, aerospace, and medical fields. However, working with C799 Al2O3 ceramic pipes presents specific challenges due to the material’s hardness and brittleness.

To efficiently cut through such tough ceramic pipes, resin diamond cutting discs offer a reliable solution. This article explores the properties of C799 Al2O3 ceramic pipe, its applications, and why resin diamond cutting discs are ideal for cutting this material.

What is C799 Al2O3 Ceramic Pipe?

C799 Al2O3 ceramic is a high-purity aluminum oxide ceramic material that is commonly used for its remarkable properties such as hardness, wear resistance, and high-temperature stability. It is often utilized in industries where durability and resistance to corrosion and abrasion are crucial.

Key Characteristics of C799 Al2O3 Ceramic:

* High Hardness: Al2O3 has a Mohs hardness of around 9, making it second only to diamond in terms of hardness.

* Thermal Resistance: C799 Al2O3 ceramic can withstand temperatures upwards of 1700°C, making it suitable for high-temperature environments.

* Chemical Resistance: It is highly resistant to corrosive substances, which makes it ideal for applications in chemically aggressive environments.

* Electrical Insulation: C799 Al2O3 ceramic also has excellent electrical insulating properties, making it useful for electrical and electronic applications.

* Brittleness: While tough in compression, aluminum oxide is a brittle material under tension, which can make cutting and machining it more challenging.

Challenges in Cutting C799 Al2O3 Ceramic Pipe:

Despite its many advantages, C799 Al2O3 ceramic is difficult to cut due to its brittleness and hardness. Traditional cutting methods often result in cracking or chipping. As a result, special tools are needed for accurate, clean cuts, and this is where diamond cutting tools, particularly resin diamond cutting discs, come into play.

Applications of C799 Al2O3 Ceramic Pipe

C799 Al2O3 ceramic pipes are used in a variety of industrial and scientific applications. Some of the most common include:

* Chemical Processing:

Pumps, valves, and pipes in the chemical and pharmaceutical industries. The material’s chemical resistance ensures that it will not corrode when exposed to harsh chemicals.

* Aerospace Industry:

-

C799 Al2O3 ceramic is used in aerospace components due to its high-temperature tolerance and mechanical strength. Ceramic pipes are used in engine components, nozzles, and insulating parts.

* Medical Equipment:

-

-

Due to its biocompatibility and chemical stability, C799 Al2O3 ceramic is also used in medical devices such as surgical tools, implants, and biochemical analysis equipment.

-

* Electrical Insulation:

-

-

The insulating properties of C799 Al2O3 ceramic make it ideal for high-voltage applications such as electrical insulators, capacitors, and resistors.

-

* Wear-Resistant Components:

-

-

Used for abrasive-resistant components like lining materials for equipment that deal with high wear and tear, such as mining equipment or pipe linings in slurry transportation.

-

Given the wide range of applications, precision cutting of C799 Al2O3 ceramic pipes is critical to ensure the pieces fit the required specifications without compromising the integrity of the material.

How to Choose Diamond Cutting Disc for Cutting C799 Al2O3 Ceramic Pipe?

Choosing the right diamond cutting disc for cutting C799 Al2O3 ceramic pipes is crucial to achieving precise, clean cuts without damaging the material. Here are the key factors to consider:

1. Abrasive Material:

-

Diamond abrasives are the best choice for cutting hard ceramic materials. Diamond is the hardest material known to man and can effectively cut through high-purity ceramic materials like C799 Al2O3 without damaging the pipe.

2. Bond Type:

-

Resin Bond is the preferred option for cutting C799 Al2O3 ceramic pipes. Resin bonds offer a balance between high cutting efficiency and surface finish. The flexibility of resin bond helps prevent excessive cracking and ensures smooth cutting action.

-

Metal Bond wheels can also be used for tougher materials, but they tend to be more rigid and are not as suitable for delicate ceramic materials.

-

Vitrified Bond is another option, which provides a high level of precision and longer wheel life, but may be less efficient in terms of cutting speed for hard ceramics.

3. Grit Size:

-

For ceramic materials like C799 Al2O3, fine-grit diamond cutting discs (ranging from 80 to 600 grit) are usually preferred. A fine grit allows for smooth, controlled cutting while minimizing the risk of cracks and chips in the ceramic.

4. Cutting Speed:

-

The cutting speed should be controlled to avoid overheating the ceramic pipe. Excessive heat can lead to cracks, reduced cutting efficiency, and uneven cuts. Using a slow and steady cutting motion with appropriate cooling (e.g., water or coolant) can enhance the cutting process.

5. Cooling and Lubrication:

-

While resin diamond cutting discs do not typically generate as much heat as metal-bonded wheels, proper cooling and lubrication are still essential to avoid overheating the ceramic material. A steady flow of coolant or water during cutting can also help extend the life of the cutting disc.

6. Size and Thickness of the Cutting Disc:

-

Depending on the size and thickness of the C799 Al2O3 ceramic pipe, the cutting disc size and thickness should be selected. Typically, a thinner cutting disc is ideal for precise, clean cuts in thinner pipes, while thicker discs are used for larger, heavier-duty cutting tasks.

Advantages of Resin Diamond Cutting Disc for Cutting C799 Al2O3 Ceramic Pipe

Using a resin diamond cutting disc for cutting C799 Al2O3 ceramic pipes offers several advantages, making it the tool of choice in the industry:

1. Superior Cutting Efficiency:

- Resin diamond cutting discs provide fast cutting speeds while maintaining precision. They can easily cut through the tough material without the need for excessive pressure, which helps maintain the integrity of the pipe.

2. Clean and Smooth Cuts:

- The combination of diamond abrasives and resin bonding creates a smooth cutting surface. This is important for cutting C799 Al2O3 ceramic pipes to precise dimensions without creating chips or cracks that could compromise their function.

3. Reduced Risk of Cracking:

- Resin bond discs are less rigid than metal-bonded discs, making them more forgiving when working with brittle materials like ceramics. This flexibility helps minimize the risk of causing cracks in the ceramic during cutting.

4. Long Tool Life:

- The durability of diamond abrasives ensures that the cutting discs last longer, reducing the frequency of disc replacement and improving overall cost-efficiency in the production process.

5. Minimal Heat Generation:

- The resin bond helps dissipate heat more effectively than other bond types, reducing the risk of thermal damage to the ceramic. This is crucial for materials like C799 Al2O3, which can crack or become weakened by excessive heat.

6. Reduced Material Loss:

- Resin diamond cutting discs are designed to minimize material waste, allowing for more precise cuts and reducing the need for post-cutting finishing or rework.

7. Versatility:

- Resin diamond cutting discs can be used for various cutting tasks, including straight cutting, shaping, and profiling, providing versatile solutions for manufacturers working with C799 Al2O3 ceramic pipes.

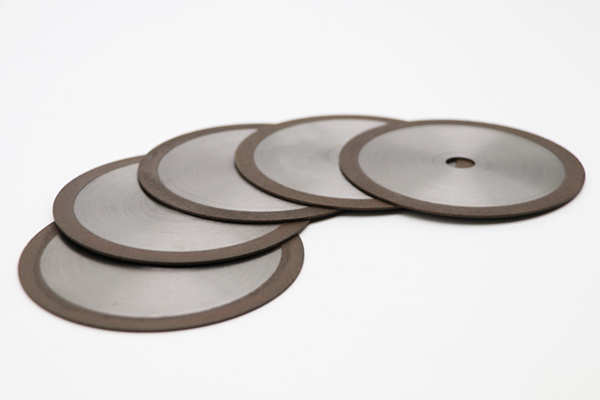

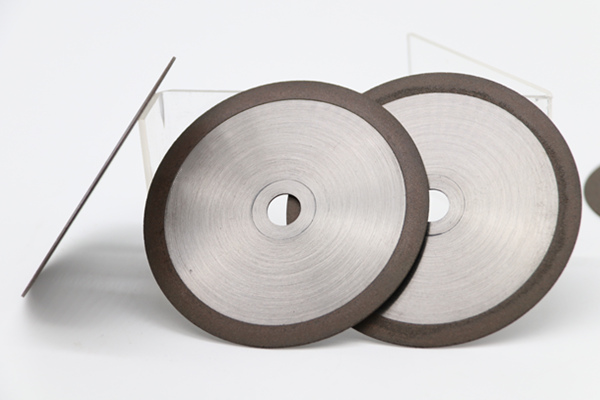

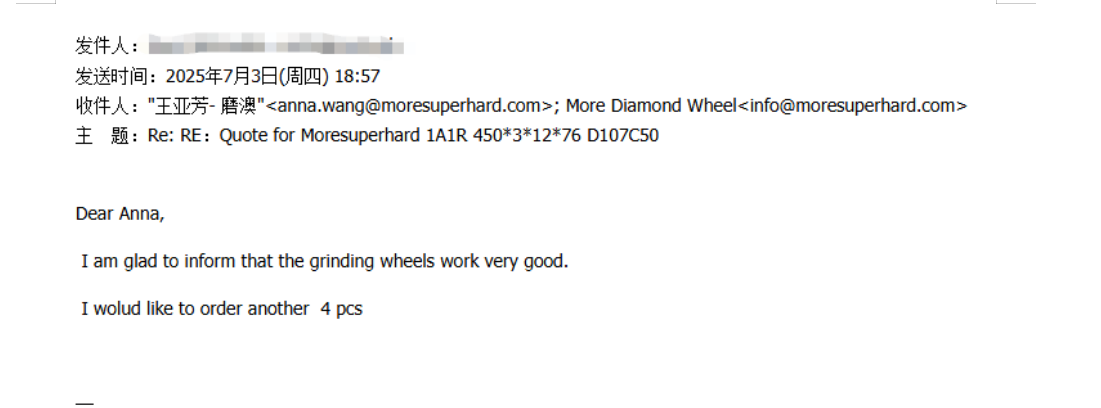

Recently Moresuperhard received one inquiry good feedback about resin diamond cutting disc for cutting C799 Al2O3 Ceramic Pipe,lets see it together:

| Bond of cutting disc | Resin diamond cutting disc |

| Size | 1A1R D450*T3*X10*H76, D107C50, |

| Workpiece | C799 Al2O3 Ceramic Pipe |

—EDITOR: Doris Hu, Anna Wang

—POST: Doris Hu