Case of Resin CBN Grinding Wheel for Grinding Brake disc

The brake disc is a crucial component in modern vehicles, responsible for converting the kinetic energy of the moving vehicle into heat energy through friction when the brake pads make contact with the disc. Given the high performance and safety requirements in the automotive industry, the manufacturing process of brake discs demands precision, consistency, and durability. To meet these requirements, Resin CBN (Cubic Boron Nitride) grinding wheels have emerged as a preferred solution for grinding brake discs.

What is a Brake Disc?

A brake disc (also known as a brake rotor) is a key component in a vehicle’s braking system. It is typically a circular metal disc that is mounted on the wheel hub and works in tandem with the brake pads to slow down or stop the vehicle.

There are two main types of brake discs:

* Vented Brake Discs: These discs have internal air vents to help dissipate heat generated during braking, preventing overheating.

* Solid Brake Discs: These are one-piece solid discs, often used in simpler braking systems.

Brake discs are made of high-performance materials such as cast iron, carbon composites, and high-alloy steel, which are durable enough to withstand the heat, friction, and stress of braking.

Manufacturing Process of Brake Discs

The manufacturing process of brake discs involves several key steps to ensure that the final product has the required strength, durability, and precision. The process is typically as follows:

1. Material Selection

The material chosen for brake discs must possess high thermal conductivity, wear resistance, and the ability to withstand high temperatures. Common materials used in brake disc manufacturing include:

-

Cast iron: Most commonly used for passenger vehicles due to its strength, cost-effectiveness, and ease of machining.

-

Carbon composite: Used for high-performance applications, such as racing or performance vehicles, due to its lightweight and high heat tolerance.

-

High-alloy steel: Used for high-performance and heavy-duty applications because of its superior strength and durability.

2. Casting/Forging

Brake discs are typically cast or forged depending on the material used:

-

Casting: The selected material is melted and poured into molds, where it solidifies into the brake disc shape.

-

Forging: The material is heated and shaped under pressure to form the brake disc, providing better mechanical properties.

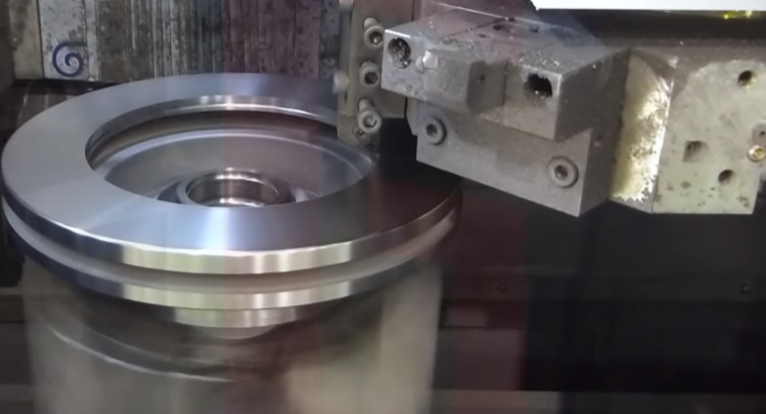

3. Machining

Once the disc has been cast or forged, it undergoes rough machining. The disc’s outer diameter, thickness, and vent holes (if vented) are precisely machined. The disc is also pre-drilled to accommodate the wheel hub and bolts.

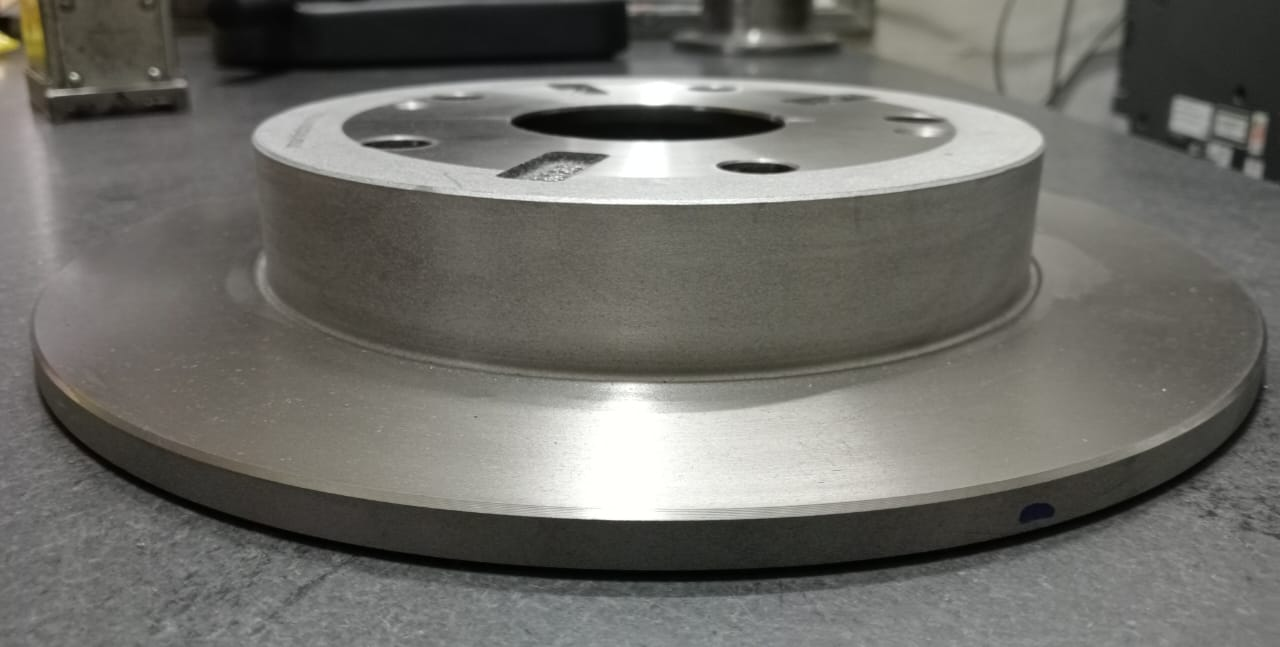

4. Grinding

The grinding process is one of the most critical steps in the brake disc manufacturing process. It is performed to achieve:

-

Precision flatness: Ensures uniformity of thickness across the disc.

-

Surface finish: Achieves a smooth surface for better contact with brake pads.

-

Dimensional accuracy: Ensures the brake disc meets precise tolerances.

Grinding is typically carried out using superabrasive wheels, such as CBN grinding wheels, which ensure superior performance when grinding hard materials.

5. Final Inspection

After grinding, brake discs undergo strict inspection to ensure they meet quality and safety standards. This includes testing for material defects, flatness, dimensional accuracy, and surface finish. Brake discs that pass the inspection are then ready for further finishing processes such as painting or coating.

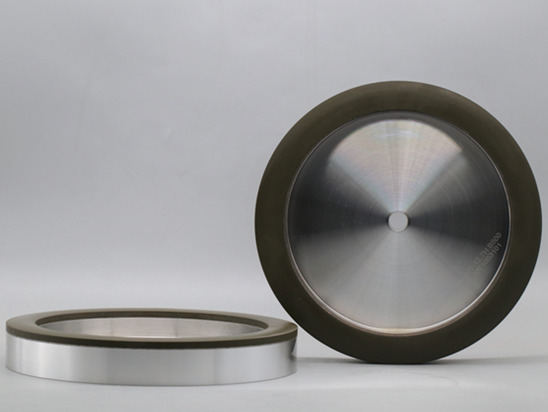

Application of Resin CBN Grinding Wheel for Grinding Brake Discs

Resin CBN grinding wheels are increasingly used for grinding brake discs due to their superior ability to handle the tough materials used in brake disc manufacturing. Here’s how resin CBN wheels fit into the grinding process for brake discs:

1. Grinding Cast Iron Brake Discs

For cast iron brake discs, resin-bonded CBN grinding wheels offer high grinding efficiency, delivering fine surface finishes and accurate dimensions. CBN is highly effective at grinding ferrous materials, such as cast iron, without excessive wear or the generation of high heat that could cause thermal damage to the material.

2. Grinding High-Alloy Steel Brake Discs

High-alloy steel brake discs are often used in high-performance vehicles and heavy-duty applications. Resin CBN grinding wheels are ideal for these applications, offering excellent wear resistance and durability. These wheels maintain their cutting ability even when grinding extremely hard materials, ensuring long-term performance and minimal downtime.

3. Precision Grinding for Performance Brake Discs

For performance brake discs, such as carbon-carbon discs used in high-end sports cars or racing vehicles, resin CBN wheels provide the necessary precision. These wheels are designed to maintain sharp edges for high-precision grinding, achieving smooth finishes and tight tolerances required for performance and safety.

Advantages of Resin CBN Grinding Wheel for Grinding Brake Discs

The use of resin CBN grinding wheels in the grinding of brake discs offers several advantages:

1. High Grinding Efficiency

Resin-bonded CBN grinding wheels are known for their superior material removal rates, meaning that they can grind faster and more efficiently compared to conventional abrasives. This increases overall productivity and reduces cycle times.

2. Longer Tool Life

CBN (Cubic Boron Nitride) is one of the hardest known materials, second only to diamond. This gives resin CBN grinding wheels a longer tool life, allowing them to last much longer than traditional abrasive wheels, thereby reducing maintenance costs and downtime.

3. Superior Surface Finish

One of the most critical factors in the performance of brake discs is the surface finish. Resin CBN grinding wheels are capable of achieving superior surface finishes with low surface roughness (Ra) values, ensuring smooth contact between the brake pads and the disc. This leads to better braking performance and reduced wear on the brake pads.

4. Precision and Dimensional Accuracy

Resin CBN wheels maintain consistent dimensional accuracy, ensuring that brake discs meet the required specifications for performance. These wheels are capable of achieving tight tolerances, which is essential for ensuring the safety and performance of the braking system.

5. Reduced Thermal Damage

Thermal damage, such as disc warping or discoloration, is a major concern when grinding hard materials. Resin CBN wheels generate less heat during grinding compared to other abrasives, helping to minimize thermal damage and preserve the material integrity of the brake disc.

6. Versatility

Resin CBN grinding wheels can be used in a variety of grinding processes, including surface grinding, cylindrical grinding, and centerless grinding. This versatility makes them suitable for a wide range of brake disc applications, from standard to high-performance discs.

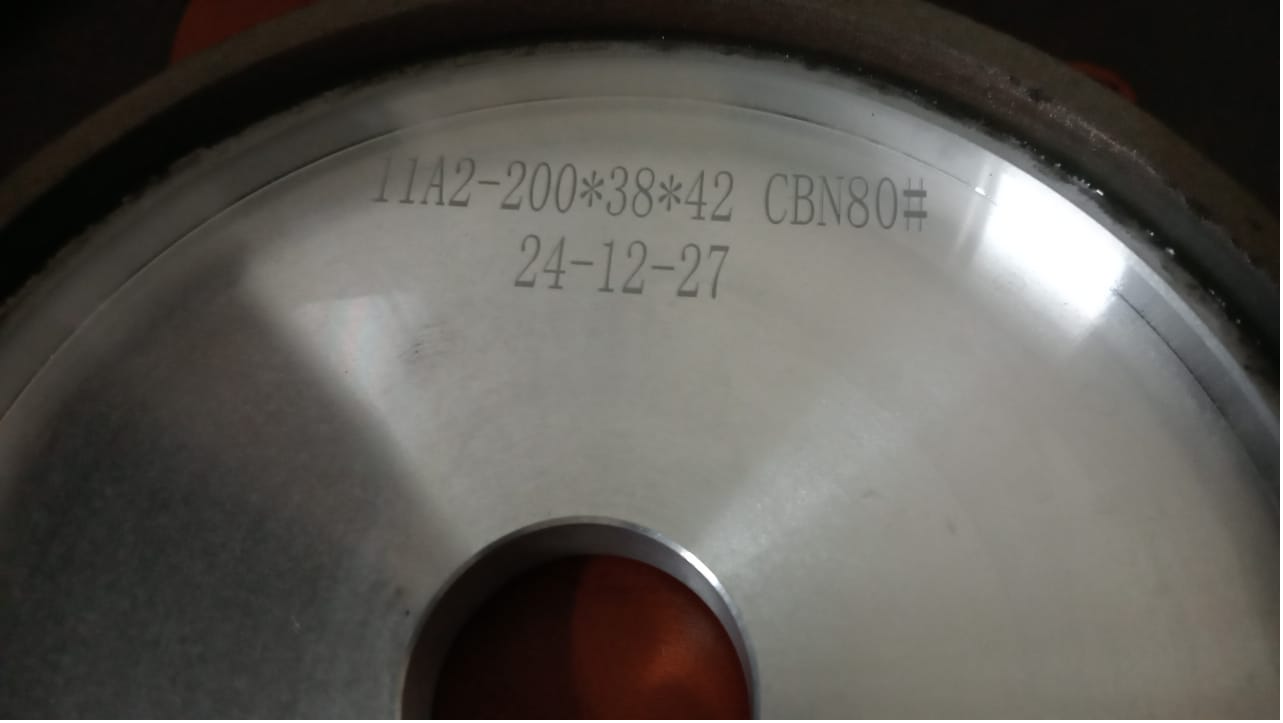

Recently, Moresuperhard has received one inquiry about grinding brake disc, lets see it together:

| Grinding wheel | Resin bond CBN wheel | 11A2 220-36-38-6U-10X |

| workpiece | Brake pads FG260 gray cast iron castings | |

| Surface roughness | Ra1.2-1.5 | |

| Particle size | 80# | |

| Feedback | customer said the cbn wheel with good performance | |